I read through a couple of the DIY Tormach Stand threads on this site. Good stuff. I didn't see anything about the DIY plans that tormach has on their website for an 1100 stand.

http://www.tormach.com/uploads/426/T...1212A-zip.html

Anyone built one of these? Thoughts? Its made of wood...wondering how well that would hold up. My thinking is if I save money by building my own stand I can use that savings to buy the power drawbar.

Thread: DIY Tormach Stand

Results 1 to 20 of 63

-

01-06-2016, 12:12 AM #1

Registered

Registered

- Join Date

- Aug 2015

- Posts

- 58

DIY Tormach Stand

-

01-06-2016, 01:05 AM #2

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 328

Re: DIY Tormach Stand

Wood is for sheds don't make that mistake it will not make you happy. these machines are very heavy if you are worried about budget check your local welding shops they should have no problem at all making a heavy duty stand. i built mine but it still cost me 650 for materials and some bending work. Mine is way over kill so I will guess you can have a shop do one around 400-600 out of tubing with a top plate just don't forget to add leveling adjusters.

-

01-06-2016, 04:59 PM #3

Registered

Registered

- Join Date

- Aug 2015

- Posts

- 58

Re: DIY Tormach Stand

You're probably right. I wouldn't worry about the wood if it weren't for the fact that its going to be moist/wet. 1000lbs isn't that much for a solid wood frame, but with moisture and movement I think your assessment is probably correct I would end up unhappy.

Thanks for the thoughts.

-

01-06-2016, 06:08 PM #4

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1943

Re: DIY Tormach Stand

I don't have a Tormach, but my father had an RF-40 size machine on a wood table for about 20 years without any problem. Construction was 4x4 legs, 2x6 skirt under the 3/4" plywood top, with 2 2x6's running right under the machine base. 1/4" plywood around 3 sides and a lower shelf with 2x4 skirt to support. Had a scrap of formica from a cabinet shop on the top to make it easier to clean. He had that machine on that table for probably 20 years with absolutely no problems. He ran mist coolant and it was a manual machine for what its worth.

I had an RF-25 size machine on a similar wood stand myself. Design was similar to my father's. That machine made a move from Texas to Illinois in a trailer while still mounted to the stand without any problem. Was on that table for 15 or so years and left still mounted to it when I sold it.

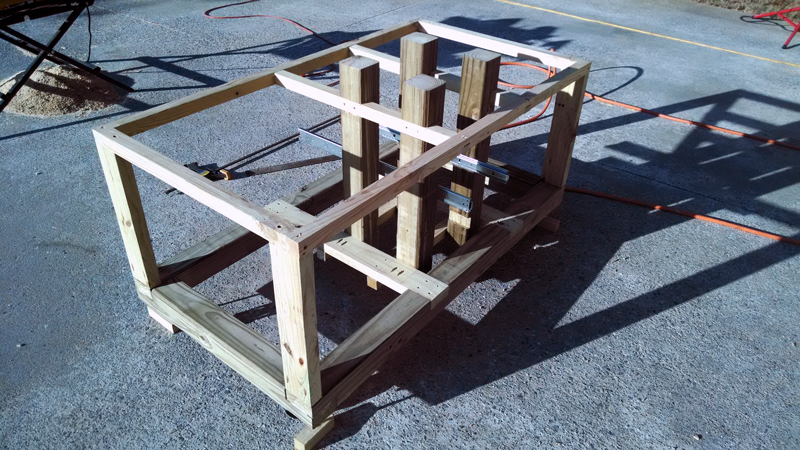

Coincidentally, I am currently building a wood stand that is somewhat similar to the one in your link that is for my G0704 CNC Mill. I know it is a much smaller mill (~300 lbs), but I will be doing both mist and flood coolant and have no problem thinking wood will work just fine. The tub will be fiberglassed. I do a lot of welding and happen to have enough square tubing on hand that I could make my stand structure out of steel, but I chose wood for a few reasons. First it is very fast to build. Second, with steel, I would have to pay to have things like the pan fabricated (I'm cheap and this is a hobby for me). Third, like the linked plans I will have 3 compartments and in at least one of them I will put a bank of drawers in. Making the drawers and case from wood is a lot easier than fitting slides to a metal frame. Then I would probably have to go with metal drawer pans that I don't have the tools to make myself to be consistent. Fourth, Its cheap and materials are easier for me to get. Fifth, If I don't like the design and decide to re-do it, disposing of the old stand only takes a match in the back yard (I have 2-1/2 acres in the country). I just happened to take this approach with a rolling wood workbench that I no longer needed. Attached is a picture of what I have so far. Still have to fiberglass, paint, and start mounting the mill and stuff.

Before anyone blasts me, I did not say wood was better. I only say that wood can work and work well. It also has some pretty good vibration dampening characteristics.

Attachment 303034

-

01-06-2016, 08:47 PM #5

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1538

Re: DIY Tormach Stand

Wood under load will slowly keep sagging, maybe only a tiny amount, but if the changing stresses affect the base seating, it can affect the machine accuracy.

Because of this, if using wood for the stand I would advise using a base connection that isolates sag, eg 3 point contact. Steel sags also - but it reaches its elastic limit and stops.

This video covers some of this.

Keen

https://www.youtube.com/watch?v=z_Cz3DSwA1E

-

01-06-2016, 10:04 PM #6

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: DIY Tormach Stand

That's why if you are going to use wood for the stand the 3 to 4 points that the mill sits on should be vertical and not a span of lumber. Sitting the mill on the tops of 3 to 4 posts that have contact points on the concrete below should result in something that does not change much other than with temperature.

-

01-06-2016, 11:51 PM #7

Registered

Registered

- Join Date

- Aug 2015

- Posts

- 58

Re: DIY Tormach Stand

Its funny you posted that video. I just ran across it yesterday.

All good points. Thanks you guys. If I go with the plans from the tormach site I'll update on how its working out. Right now I'm leaning slightly towards a steel frame. I'm a bit of a woodworker though so there is a very core part of me that really wants to build it from wood.

Kenny I think you are right, if the actually support is all end grain there would be very little movement. I just don't know that I can quantify how much "sag" there could be. And if I could identify that, I'm not sure I know how much sag is acceptable. Maybe if I re-level and tram the machine every 6 months? I don't know, I hate to create a nightmare maintenance situation for myself. I'm probably overthinking this.

-

01-06-2016, 11:57 PM #8

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

-

01-07-2016, 05:45 PM #9

Registered

Registered

- Join Date

- Aug 2015

- Posts

- 58

Re: DIY Tormach Stand

-

01-07-2016, 07:48 PM #10

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

-

01-07-2016, 08:11 PM #11

Member

Member

- Join Date

- Feb 2009

- Posts

- 152

-

01-09-2016, 10:40 AM #12

Registered

Registered

- Join Date

- Apr 2015

- Posts

- 93

Re: DIY Tormach Stand

Lets just face reality, steel is a better material to build stands for heavy precision CNC machines.

To the OP,

Forget about a wood stand! You bought an $8500 mill that deserves a steel stand. Just buy the stand and don't look back unless you intend to build steel stand or enclosure that will be better than the Tormach setup. Believe me when that mill is delivered and you get it all setup you wont regret it one bit. It's designed for the mill and it looks much more professional too. You can make much better money doing a CNC job in the time you will take to fabricate an equivalent stand with chip trays.

-

01-09-2016, 04:05 PM #13

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 2151

Re: DIY Tormach Stand

+1 on the Tormach stand, it is worth every penny. Helps keep the mill stable, level and in tram providing long term precision setup.

If I was to build one to save money it would be a fixed cmu block base filled with quickcrete and steel plate embeds to bolt mill to .

.

Could do that for few hundred dollars and have a very solid but fixed base. There are threads around here on epoxy granite machines , no reason this concept could not be applied to base!

-

01-09-2016, 06:22 PM #14

Registered

Registered

- Join Date

- Sep 2009

- Posts

- 624

Re: DIY Tormach Stand

Don't do it. I built one from the Tormach plans when I first got my 1100. It went together just as Tormach said...and it's just not adequate. Biggest issue is that it's incompatible with most coolant- especially flood. It will leak, it will get spongy. And it's a major woodworking project-I've got a complete wood shop, and it was still a pain to build. I put up with it for six months and junked it, bought the deluxe stand. Those plans were from a time when Tormach was trying to give home shops a low-cost entry point; a cheap way out of spending another 500 bucks (back then). There have been some decent home-brew stands documented here (along with some not-so-obvious problems), but the wooden stand just isn't a good choice.

SDM has a good (and approved) alternative to the PDB that one can build for about half the price of the Tormach option. It's manual, won't work with the ATC, but for many purposes is acceptable. If you poke around this and other CNCzone forums, you'll find a lot of drawbar options, some that should work with the ATC.

-

01-10-2016, 05:38 PM #15

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 291

Re: DIY Tormach Stand

I have had mine with deluxe stand for a few years now and would build one myself. Unless you have had the deluxe, or any other mill/stand, you don't know what you want and don't. I need a full enclosure with a much better designed coolant system and room up front. I don't use the compartments underneath for much but stock storage and I can lower my chip tray and make a better drain. For the most part the stand is more than adequate though.

-

01-11-2016, 09:56 PM #16

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 141

Re: DIY Tormach Stand

This post kind of reminds of cars that you see driving around with a piece of plexiglass duct tapped in to replace a window, sure it works, keeps more of the weather out and was cheap but it's not the best fix nor is it the right thing to do. If you are fine with driving around with a piece of plexiglass for a window, go for it but I'll stick with my steel stand.

-

01-12-2016, 02:13 AM #17

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: DIY Tormach Stand

All Plexiglass......

-

01-12-2016, 02:25 AM #18

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: DIY Tormach Stand

Meanwhile...the Tormach 440 stand is bolt together sheet metal. Which do you think is more stable. The sheet metal stand bolted together with 1/4x20 bolts and nuts or the glued and screwed completely bonded structure I posted above wrapped in 1/2" plywood with a bonded in Fiberglass pan? I'll give you a hint. It's not the one made of sheet metal.

Built properly I'll put my inferior wood stand up against the sheet metal rubbish all day long for a machine the size of the G0704.

-

01-12-2016, 06:15 AM #19

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 180

Re: DIY Tormach Stand

Actually, those plans were from back before Tormach offered any other options...

When I bought my mill back in 2005 Tormach didn't have any type of stand for sale. The only thing Greg had to offer was plans for the wooden stand. His suggestions were to use a thin coat of bondo over the entire surface of the wood which would make it appear to be made of steel. I made the mistake of assembling my stand in the basement, so when I later made a mess of the bondo covering I wasn't able to get the stand back outside to sand it down properly. I then coated it with epoxy floor paint sealing in the crappy bondo work... The pitted resulting surface holds chips really well. But the stand itself is a really sturdy design and has no problems holding the mill. I'm sure the wood swells a bit in the humid months though it is in a temperature controlled basement. I've never really run flood coolant either.

When I bought my mill back in 2005 Tormach didn't have any type of stand for sale. The only thing Greg had to offer was plans for the wooden stand. His suggestions were to use a thin coat of bondo over the entire surface of the wood which would make it appear to be made of steel. I made the mistake of assembling my stand in the basement, so when I later made a mess of the bondo covering I wasn't able to get the stand back outside to sand it down properly. I then coated it with epoxy floor paint sealing in the crappy bondo work... The pitted resulting surface holds chips really well. But the stand itself is a really sturdy design and has no problems holding the mill. I'm sure the wood swells a bit in the humid months though it is in a temperature controlled basement. I've never really run flood coolant either.

If I used the mill more, I would definitely purchase a real stand for it now.

Dave

-

01-12-2016, 05:24 PM #20

Registered

Registered

- Join Date

- Oct 2004

- Posts

- 298

Re: DIY Tormach Stand

I'd hold back judgement until you see the stand in person. The 440 stand is sheet metal, BUT it's surprisingly sturdy when it's together. The final product is more than the sum of its parts or something like that :-) However, a glued and screwed wood structure can also be pretty sturdy, but only if the design was done well.

I'm not saying either one is better than the other, but simply that in much the same way you can make wood very sturdy, the sheet metal on the Tormach stand is made very sturdy. Both rely on design to make for a good stand.YouTube Channel: https://www.youtube.com/c/RobertCowanDIY

Similar Threads

-

Tormach Stand or Build your Own?

By KSky in forum Tormach Personal CNC MillReplies: 4Last Post: 07-11-2014, 03:22 PM -

Some Tormach and DIY stand pics

By keen in forum Tormach Personal CNC MillReplies: 17Last Post: 09-10-2007, 09:33 PM -

Tormach DIY Stand

By kentavv in forum Tormach Personal CNC MillReplies: 12Last Post: 04-16-2007, 12:19 AM -

How Do You Like The Deluxe Tormach Stand?

By Willyb in forum Tormach Personal CNC MillReplies: 3Last Post: 01-31-2007, 04:38 PM -

Tormach Stand (Base)

By nutzenboltz in forum Tormach Personal CNC MillReplies: 2Last Post: 10-07-2006, 04:53 AM

Reply With Quote

Reply With Quote