Thread: THE GRIZZ

Results 281 to 300 of 726

-

06-16-2017, 02:32 AM #281

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

-

06-16-2017, 09:21 PM #282

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

I just need to rant a touch! While Nick does some tin work on the Grizz, I took the opportunity to put the saddle on the big new granite surface plate and test it with a DTI. It's almost .004 out from one end to the other. As I posted earlier, the table is not only banana shaped, the working surface it tweaked up from front to back. I assembled the saddle onto the table, centered it and tightened the gib. This operation pulled the saddle to the banana shape and the whole assembly rocked on the surface plate. With the table fixed to the saddle with a tight gib, and set on the surface plate, the difference from one end of the table to the other is a whopping .018 thousandths.

This makes me ill! :tired:

I'm not an accomplished scraper and there is no local grinder large enough to accommodate the table. I would imagine getting all these pieces scraped into any sort of tolerance would cost more than the original machine. I knew this was Chinese stuff but sure thought they had these things well taken care of...apparently not! Don't know what I'm going to do.

Stuart

-

06-17-2017, 01:43 AM #283

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: THE GRIZZ

Your going to put it together and run it because the size parts that will be coming off of it most of the time will be unaffected by it. This will only last until you linear rail the table and slide later any way.

-

06-17-2017, 02:16 AM #284

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

Kenny,

You're probably correct..and we thought about putting rails on the other axis to solve the problem but I don't know how much of the work we've already done would have to be junked because of the rail retrofit. I'm just pissed that the thing is so out of whack...damn those Chinese. I don't know what I expected for $1200 dollars.

We might just go ahead and try to level this thing out ourselves. The only daunting thing for me is getting the dove tails of the table straight and true with each other. I think I would need a long camel back straightedge with some type of 60 degree shape to it..I don't know. I just looked in the book case and remembered I have a copy of Connelly's Machine Tool Reconditioning..maybe that will give me strength to do this.

Stuart

-

06-17-2017, 02:25 AM #285

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

And then this happened!!!!! Happy Friday :cheers:

- Nick

(fresh off the press... for your viewing pleasure!)

https://youtu.be/0DV2wHS1C84

-

06-17-2017, 08:05 AM #286

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1526

Re: THE GRIZZ

The time spent scrapping in dovetails would be better spent on full linear rail conversion.

7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

06-17-2017, 05:06 PM #287

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: THE GRIZZ

It looks like we all make the same mistake on occasion. If you start adding up all the labor, materials and time in this already you likely won't end up very far from a used HAAS or something similar that someone else has already put the time, materials and labor into when it was manufactured.

-

06-17-2017, 05:19 PM #288

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

Kenny,

I see what you're saying and I am surprised at the cost of this thing so far but I can't really look at it in that regard. It was suppose to be a father & son project and it has worked well for that. I'm not going to add up my time on the project because it wasn't a 'job' per se, and the small size of the machine fits the available space left in the shop. This was a 'get your feet' wet kind of thing so maybe later down the road there may be a full size, factory machine in the mix, but not now.

Having said that, let me ask this. The linear rail thing on the X axis could be viable. I used 15mm Hiwin's on the Z axis and they worked well and the relative geometry of the column and spindle housing remained the same. I could use 15mm units on the X axis too but I want the location of table and saddle to stay the same and I'm not sure the 15mm Hiwins are compact enough to pull this off.

Has anyone put X linear rails on their G0704? Is there one style that is more compact than another and allows the table to stay pretty close to stock height? I have some 15mm rail but no car so I can't readily test this out...maybe I should order a car and see how this all fits together.

Thanks,

Stuart (and Nick)

-

06-17-2017, 05:53 PM #289

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: THE GRIZZ

Father son projects are priceless. No cost assessment required for those and it looks like you two are having a good time.

-

06-17-2017, 09:43 PM #290

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 220

Re: THE GRIZZ

Based on the linear rail conversion I have been working on I would go from 12.50 inches of travel to 11.86 inches of travel in the z-axis. I think it is worth it and will hopefully fix the issues I have with the machine; however the machine is not worth the money I have invested into it, but maybe I can make some money with it that will start to offset the cost.

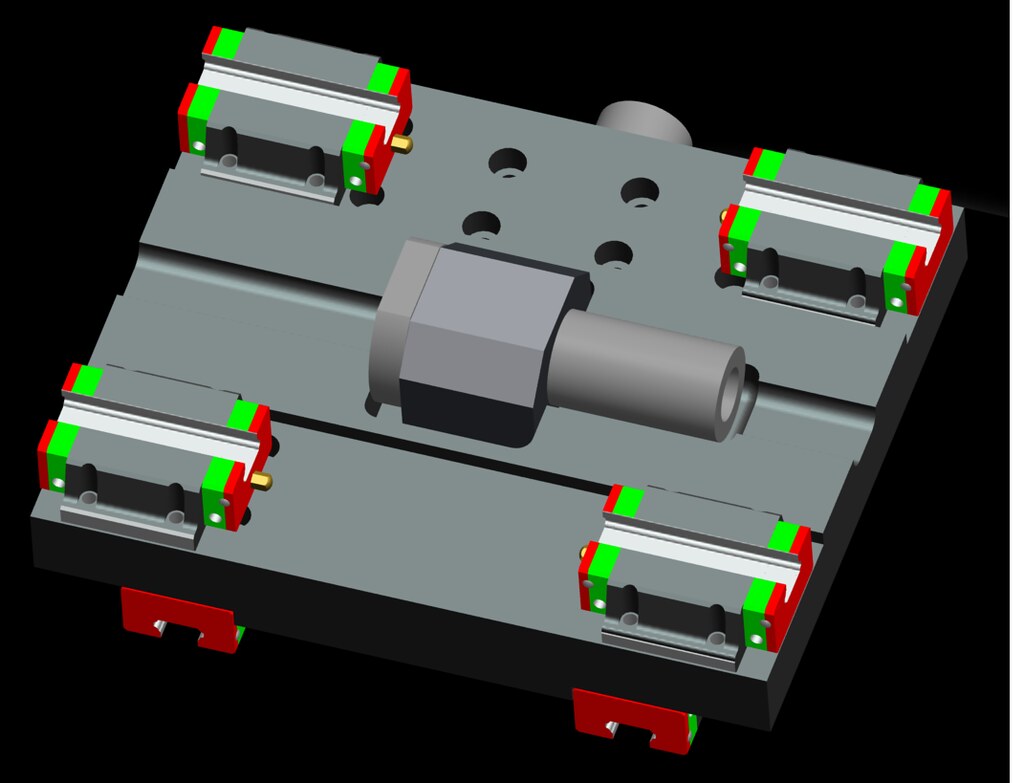

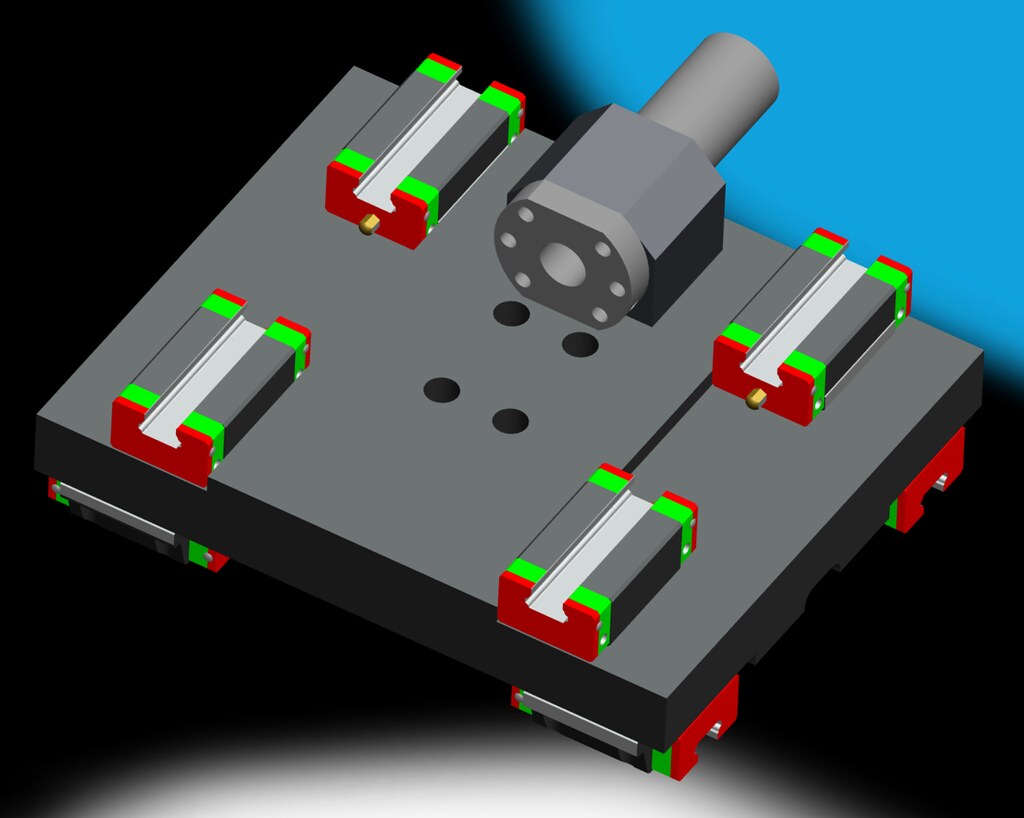

Here is a picture of the saddle I have designed and if you would like I can send you the model, but it still needs some work.

Top:

Bottom:

-

06-17-2017, 11:36 PM #291

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

Graham,

Thanks for the pictures and the offer of files. We have scratched and looked and measured all morning and think we now have a plan. As bizarre as it sounds, I'm going to add linear rails on the X axis but we're not going to fiddle with the Y axis at all..it will stay 'dovetailed'! There are too many things that would have to be modified to change the Y...and dovetails have been around for eons and have worked fine.

I think I'm going to use 15mm Hiwins with the flange bearing block as it's the only realistic way to bolt the block to the saddle..I think. We'll be able to do the machining on the Bridgeport and the position of table and saddle will remain the same, then I'll have the table top ground flat and true to the rails and we should be in business. I'm sure there will be a ton of pictures to chronicle this Chinese fire drill!

Stuart

-

06-18-2017, 02:04 AM #292

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

Some pictures from the X linear rail brain storming session.....

(the black hash would be removed for the car...)

(the last remaining question or doubt....)

-

06-18-2017, 03:25 AM #293

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1943

-

06-18-2017, 03:49 AM #294

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

I'm not Graham but I'll butt in anyway. Four of the blocks are called 'square' blocks and are tapped on the back...they go on first and are bolted from the back of the saddle. Then...the blocks called 'flange' blocks are bolted through their flanges (ears) directly to the saddle. If you look close at the flange style blocks you will see the countersinks for the socket heads that hold the 'square' blocks on underneath them. Clear as mud!

Stuart

-

06-18-2017, 07:21 AM #295

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 220

Re: THE GRIZZ

What Stuart said

I was also planning on drilling two holes through the top of my table to get to the mounting screws on the inside flanges.

Man am I excited for this! Everything you guys have done so far has been topnotch :cheers:

I am curious to see how you plan to lube the rail trucks and ball nuts...I have been struggling with that one a little.

-

06-18-2017, 05:53 PM #296

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

Well...hell! I have done a whole bunch of searches on installing linear rails on the X axis of a G0704 and haven't found one person that has actually done it, or done it and documented. Maybe I am searching incorrectly? As Nick pointed out in the pictures, we can pull this off, but the table is starting to look pretty skinny to me..yikes.

Has anyone actually done this...not just CAD drawings, but actually done it.

Graham,

The oiling for the ball nuts has already been figured out and installed...see earlier posts for that. The bearing blocks have allowances for Zerks on either end of the block so it won't be a problem to grease them..we're only dealing with the X axis so I think the outboard ends of the blocks will be accessible.

Stuart

-

06-18-2017, 08:09 PM #297

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: THE GRIZZ

I don't think so at this time. You could be a pioneer.

-

06-18-2017, 08:34 PM #298

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 220

Re: THE GRIZZ

I don’t think you have anything to lose. The table is no good as is. If it doesn’t work just use a piece of MIC-6 to replace it and reuse the rails.

-

06-18-2017, 09:03 PM #299

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: THE GRIZZ

Thanks fellas, I'm going to give it a go.

Brain storming with Nick all morning, looking at different linear rails and learning a lot. Even with a reduced 'car' height, or 'low' bearing block, too much material has to be removed from the saddle and table to make sense, from a strength standpoint..IMHO. It now becomes obvious that the answer may be to actually raise the height of the table on the saddle a bit. In our case this isn't too bad as all the bellows and tin work will stay with the saddle height and only a simple actuator for the limit switch will have to be changed.

Raising the table on the saddle allows a 28mm combined rail/block height sandwich to fit without snarfing out a ton of material from saddle or under side of table, although that isn't how much the table will be raised.

Too much info but pictures will probably follow that may make more sense. I'm amazed that this doesn't seem to have been done before..or I just can't find the thread describing it.

Stuart

-

06-19-2017, 08:32 AM #300

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1306

Re: THE GRIZZ

What about hogging a new saddle out of durabar cast iron. It is not a huge chuck of iron, and there are not that many features on it.

MarkRegards,

Mark

Similar Threads

-

enough yapping---grizz x3 //ordered// RECEIVED

By project5k in forum Benchtop MachinesReplies: 95Last Post: 01-09-2008, 11:50 AM

Reply With Quote

Reply With Quote