I see a few have installed cable chains on their Z axis, but I am curious if they then never rotate their head ? I'd prefer to keep the option for rotation, but maybe I shouldn't bother. On my other mill, I always had the tendency to position the part on the angle I needed rather than re- align the head all the time.

There does not seem to be a good way to use cable chain if your ever going to rotate the head. Anyone one come up with a nice solution ?

Thanks !

Results 1 to 12 of 12

-

02-09-2017, 01:59 AM #1

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 413

G0704 and Z Axis Cable Chain opinions ?

Chris L

-

02-09-2017, 06:33 AM #2

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

-

02-09-2017, 02:36 PM #3

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: G0704 and Z Axis Cable Chain opinions ?

It's simple, connect the cable chain to the Z slide not the head that is what I did and I just made sure I left enough slack in the motor wires to allow it to be rotated. I attached aluminum L brackets to the top of the z slide to connect the cable chains too and made a hole for the GiB adjusting screw. My coolant line also has enough slack to allow for rotating. See video below.

https://youtu.be/QucGaWH7fQI

And i will try and find some pictures of the cable chains on the machine to post up as well.

Chris

Sent from my XT1585 using Tapatalk

-

02-09-2017, 02:48 PM #4

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 413

Re: G0704 and Z Axis Cable Chain opinions ?

Well, thank you for jogging my thought process !

The conversion of this machine is a now and then event, so sometimes I forget what's left to do. One thing I was not remembering is that I will be required to put a spacer between the head and saddle yet.

The chain I have here did not have a tight enough radius to fit the way your photo shows because I have a 1/4" vertical aluminum "back wall" that stands about an inch and a half behind the saddle on each side of the column.... But, when the spacer is in place, your method should work fine for me because the spacer does not have to rotate.

A short loop between what you show and the head should not be a problem. Thanks !Chris L

-

02-09-2017, 03:19 PM #5

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: G0704 and Z Axis Cable Chain opinions ?

Hard to picture what you described, but I understand the bend radius. May have to adjust where it mounts behind the machine maybe? Mine is bending from the back plane of the column to the Z slide and the spacer doesn't come in to play. If you are looking at a newer picture it's different than because I went straight to the motor on one side. I will snap some pictures of the other side which is a pretty tight radius direct to the Z slide top and it is fine. Actually run my coolant line in that side which has the biggest bend radius requirement and it has no issues. Maybe you need a different cable chain? Mine were cheapies off eBay, this I got them for $12-14/meter shipped, will look for link, they have a really tight bend radius and worked awesome.

Sent from my XT1585 using Tapatalk

-

02-09-2017, 03:21 PM #6

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1186

Re: G0704 and Z Axis Cable Chain opinions ?

Here's the eBay link and a screen shot Incase future readers can't access link..

R38 18mm x 25mm Black Plastic Semi Closed Cable Drag Chain Wire Carrier 1M Long | eBay

Sent from my QTAIR7 using Tapatalk

-

02-09-2017, 07:20 PM #7

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 413

Re: G0704 and Z Axis Cable Chain opinions ?

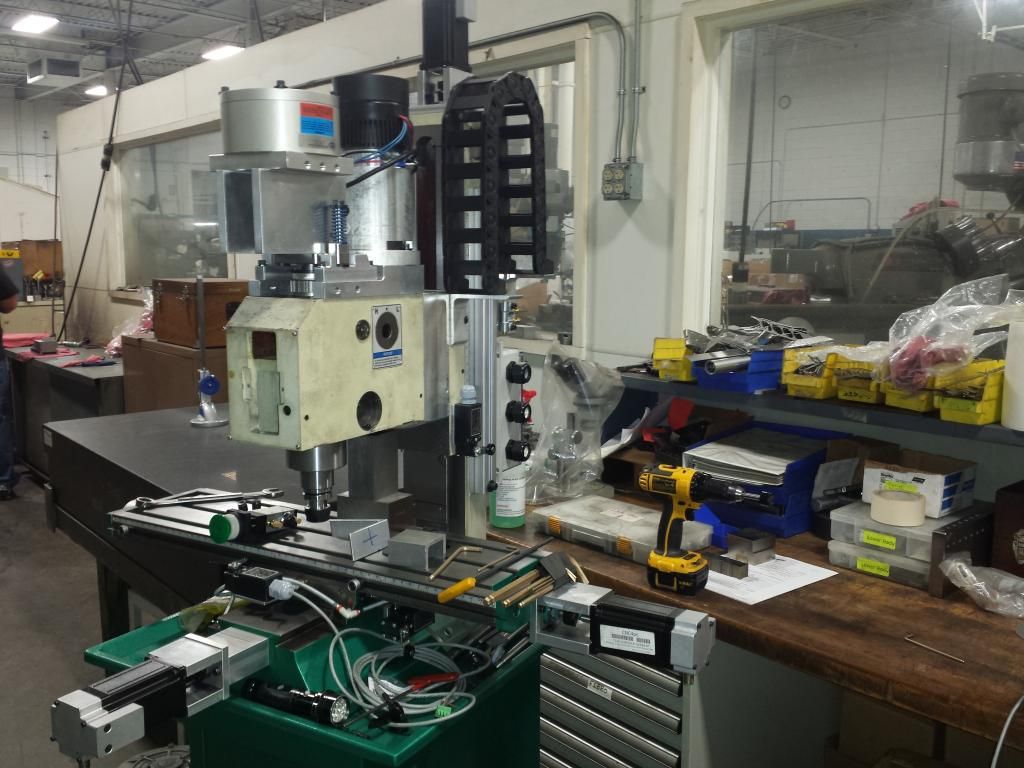

I have included some photos that show this back wall. It will eventually become part of the enclosure. The rest of the enclosure will be clear safety glass in an 80/20 framework. I did the back plane primarily to give me a spot near the top to install some longish set screws that can push from each side on the top of the column to aid in perpendicular truing.

I do plan to remove the original control box, but I figured I should run the original DC motor until it croaks, THEN spend the time for that type of rewire event, with a VFD in the control cabinet where it belongs.

I think my cable chain will be able to easily fit and work if I run behind that wall. My only issue will be maximum height as this is in a basement workshop. I've include a photo of how I did lubrication on the XY saddle, as well as the chip tray I simply fiberglassed 3 passed of glass mat over a cardboard base.Chris L

-

02-10-2017, 01:09 AM #8

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: G0704 and Z Axis Cable Chain opinions ?

I like your fiberglass over cardboard chip tray...well done sir!

Stuart

-

02-10-2017, 02:59 AM #9

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 413

Re: G0704 and Z Axis Cable Chain opinions ?

Thanks !

Now with it shiny, I wish I would have spent a little more time on making the angled sides straighter, but because I had to do the bulk of it in the basement, I used Durhams water putty as filler so as not to fill the house with Bondo smell. Everything is tapered in all the right places so that I do not get puddles. It was a fun project.

I got a break with the weather warming up just enough that I could lay up the resin in the garage over a weekend. It's a pretty large area for one guy to lay mat, but the cool weather kept things from getting tight for about an hours time.Chris L

-

02-10-2017, 03:10 AM #10

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: G0704 and Z Axis Cable Chain opinions ?

Chris,

It was planned very well. The machine sits on a platform above the coolant lake and the drainage looks perfect. I like your plumbing too..the banjo fittings look like they work well. Good work..keep those pix coming.

Stuart

-

02-10-2017, 04:57 AM #11

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 413

Re: G0704 and Z Axis Cable Chain opinions ?

For those interested in giving this a try, here is a pic of its scary looking start ! Loctite Power Grab adhesive lets you stick things together quickly. Once the shape was in place, running a bead in the corners and running your finger down them makes for a quick fillet. Because I failed to use really straight cardboard to start with, I decided to fill various spots with Durhams, but the cardboard was too flimsy to accomplish much.

To build things up a bit and add rigidity, I used plain old burlap and some old latex paint to act as a shell similar to what fiberglass would do, but give the Durhams something to grab. Before I burlapped the bottom, I put 1/8" hardboard across the large flats so there was more there than just cardboard and 3 layers of mat.

I have a large Novakon at the shop and HATE the way crap can run under that machine, so I cut some more hardboard in the footprint of the mill to go on the topside so that the mill was sitting up just that little additional bit. Yet, I know there will be coolant that will get under the machine, and did not want it to have no where to go, so I tapered a center drain area to take care of that.

I thought the resin was going to tighten up too quickly for one guy and planned on spraying it, but I did a test batch and found that with the 40 degree temps, I could just roll it on. The drains are off the shelf bar sink drains. I will be running screens in them, and the will both be plumbed to a slide out tank that will reside in the middle section of that cabinet. Unlike some other tanks I have used this one will allow me to have good DEPTH and plenty of space in the bottom before I have to clean it out (I Hope).

Finally, the machine itself is bolted down to 3/4" thick aluminum plate, but there are rigid spacers so it does not pinch the pan. The plate sites on top of a space frame I built inside the cabinet.

I sure hope to get it operational before summer as I have plenty of other things to catch up on ! Otherwise it will wait until next winter.Chris L

-

02-10-2017, 08:03 AM #12

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: G0704 and Z Axis Cable Chain opinions ?

Chris,

That is just too cool..you did good Mr. Thanks for sharing those pictures.

Similar Threads

-

Cable, chain, belt drive concept for long axis movement.

By John Hill in forum Linear and Rotary MotionReplies: 8Last Post: 01-09-2015, 08:03 PM -

Cable, chain, belt drive concept for long axis movement.

By John Hill in forum DIY CNC Router Table MachinesReplies: 0Last Post: 12-26-2014, 12:23 AM -

Looking for cable chain

By neurofen in forum DIY CNC Router Table MachinesReplies: 0Last Post: 02-19-2014, 02:03 AM -

Cable Chain

By GAWnCA in forum Mechanical Calculations/Engineering DesignReplies: 9Last Post: 11-15-2012, 05:35 PM

Reply With Quote

Reply With Quote