Hey folks!

Been a long-time fan of this forum, and I have learned a ton browsing through the various sub-forums, and researching all the knowledge that this group provides. I rebuild custom, vintage motorcycles and always have the need to make quick, custom parts for the builds (mostly in aluminum). To fill this need, awhile back I built a small CNC router, based on parts and open source designs from OpenBuilds. I got bit by the bug bad, and while the parts I was able to make were satisfying and functional, the limitations of the machine (and open source cloud-based software) pushed me toward researching a larger, more rigid machine. I briefly flirted with the idea of a tormach, but the price felt expensive for a work area that's somewhat limiting for the type of parts I wanted to make. Also, I wanted to keep the footprint of the machine fairly compact.

So after a massive amount of research over the course of a year, I found myself returning often to a machine built by a member here (@katran) named Gabriel. He built a meticulous machine based on aluminum profile and aluminum tooling plate. While nowhere near as rigid and heavy as commercial machines, it fit my footprint needs, and seemed to check the boxes of cutting area, and rigid enough to wok on the small aluminum parts and plate that I most often work with. I can't thank Gabriel enough for detailing his build. I did change a few things in my own design, but I hope that he subscribes to " imitation is the greatest form of flattery," because this build owes a lot to his vision.

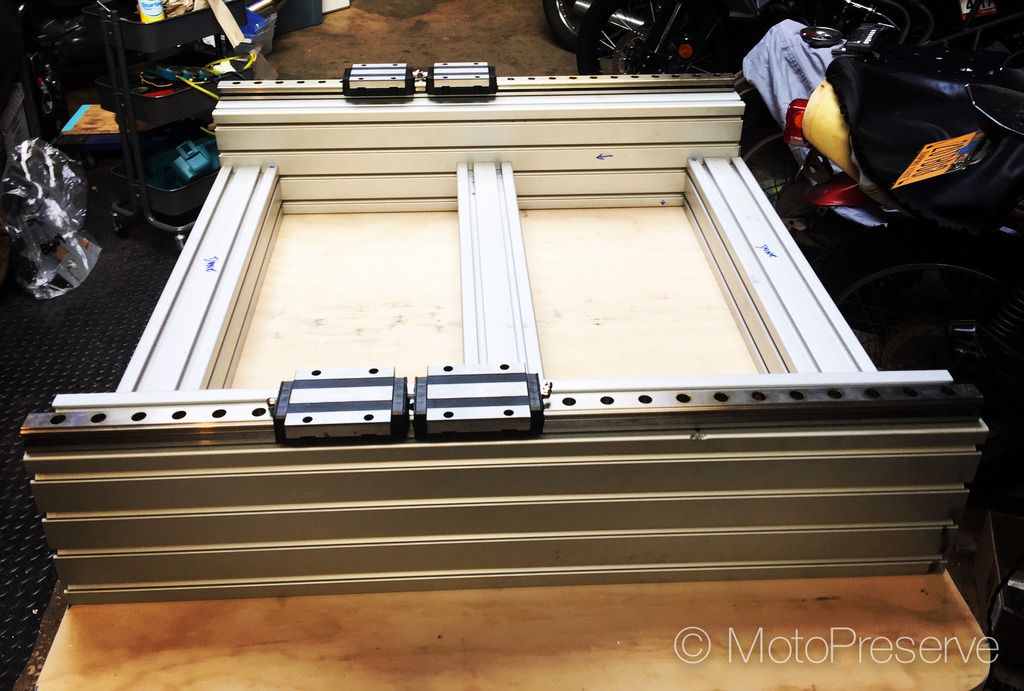

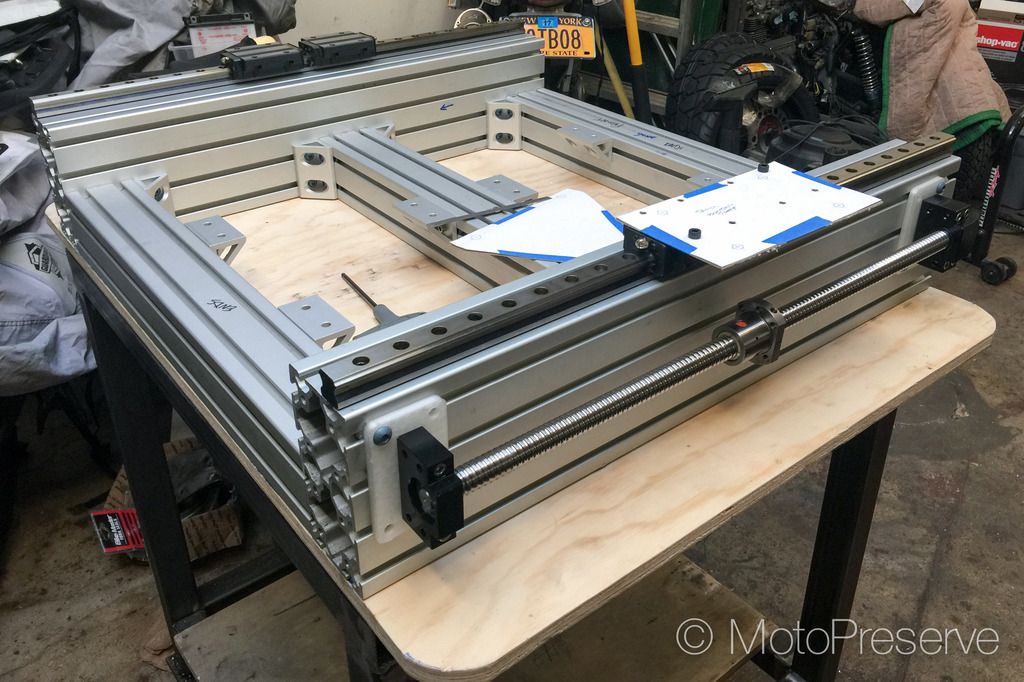

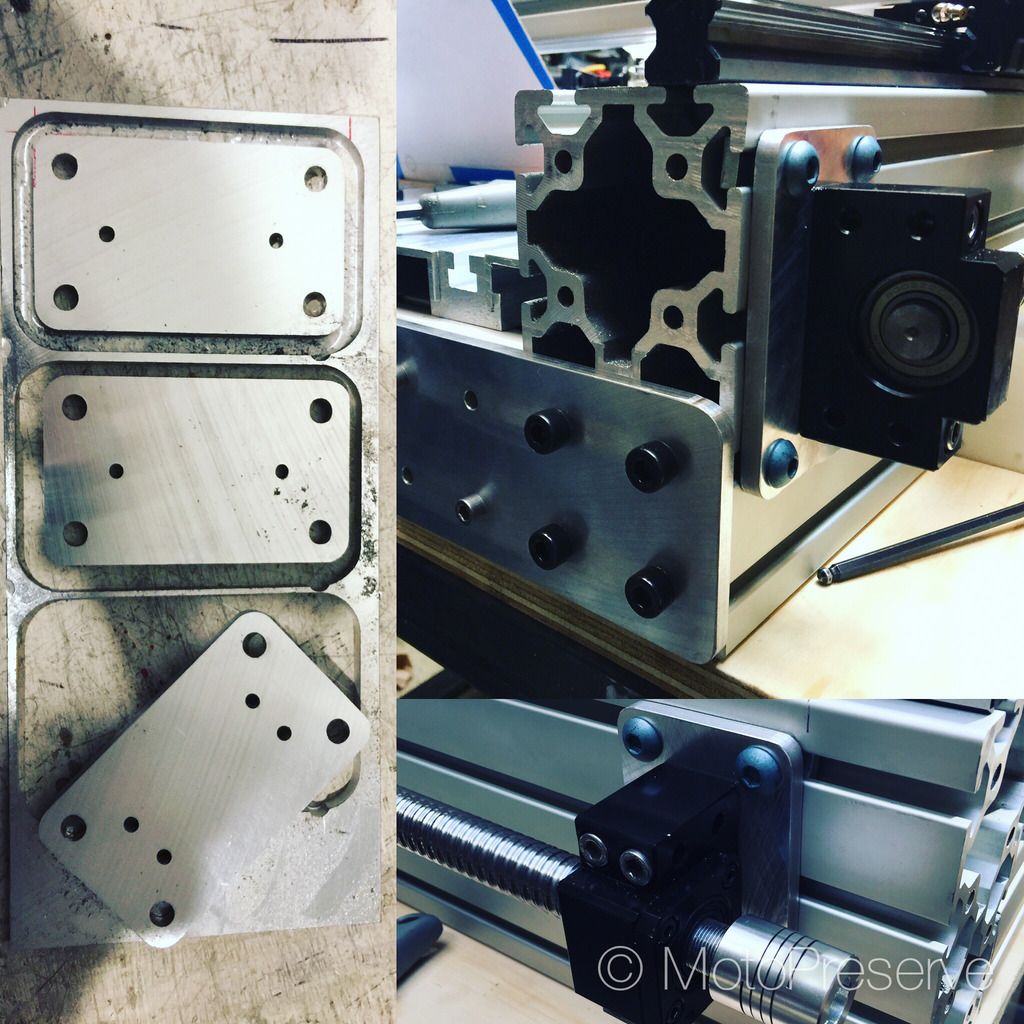

In addition to the aluminum profile and tooling plate, I went with Chinese ballscrews (dual drive on the longer axis), THK linear rails and trucks patiently purchased used on eBay (2 rails/4 trucks per axis), a Chinese water cooled spindle, Mach3 and Nema 23/600 oz size motors.

I never started a thread while I was designing and building it - but I thought I'd post up, since I am now making chips, having a ball and already producing parts from this new machine. Below is a photo of the CNC once I began initial testing - although I have added some features and will be continuing to improve in areas that I find lacking. More photos are included as attachments. Thanks for all the inspiration! Hope you enjoy...

Scott

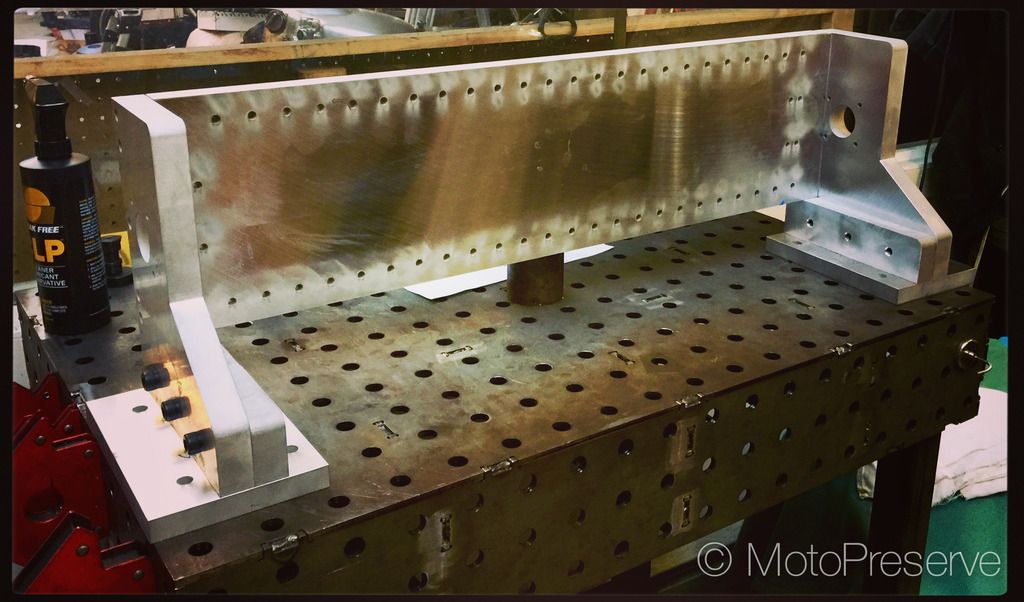

Frame coming together...

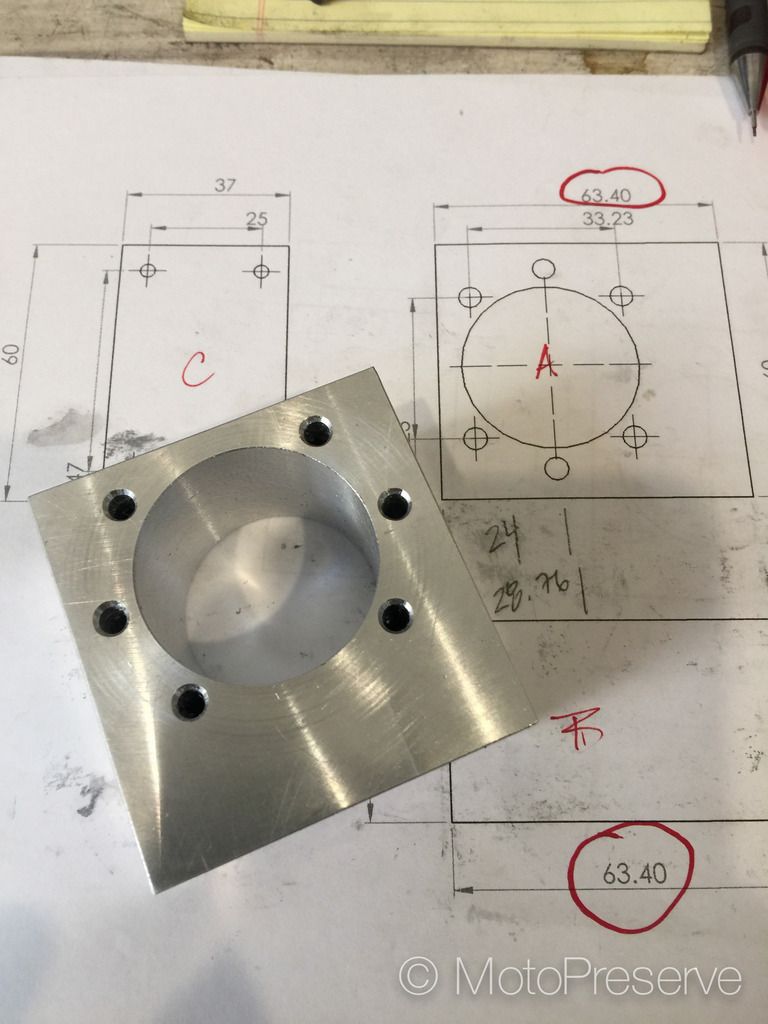

Mock-ups prevent headaches...

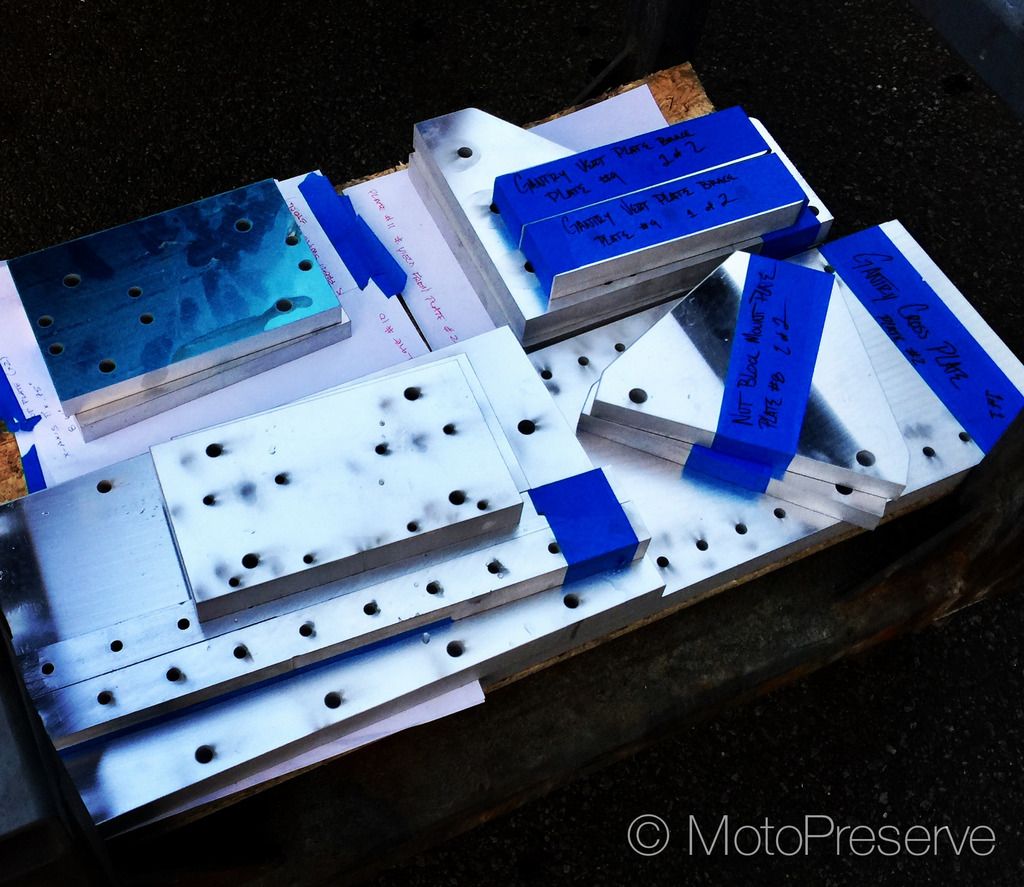

Tooling plate back from water-jetting...

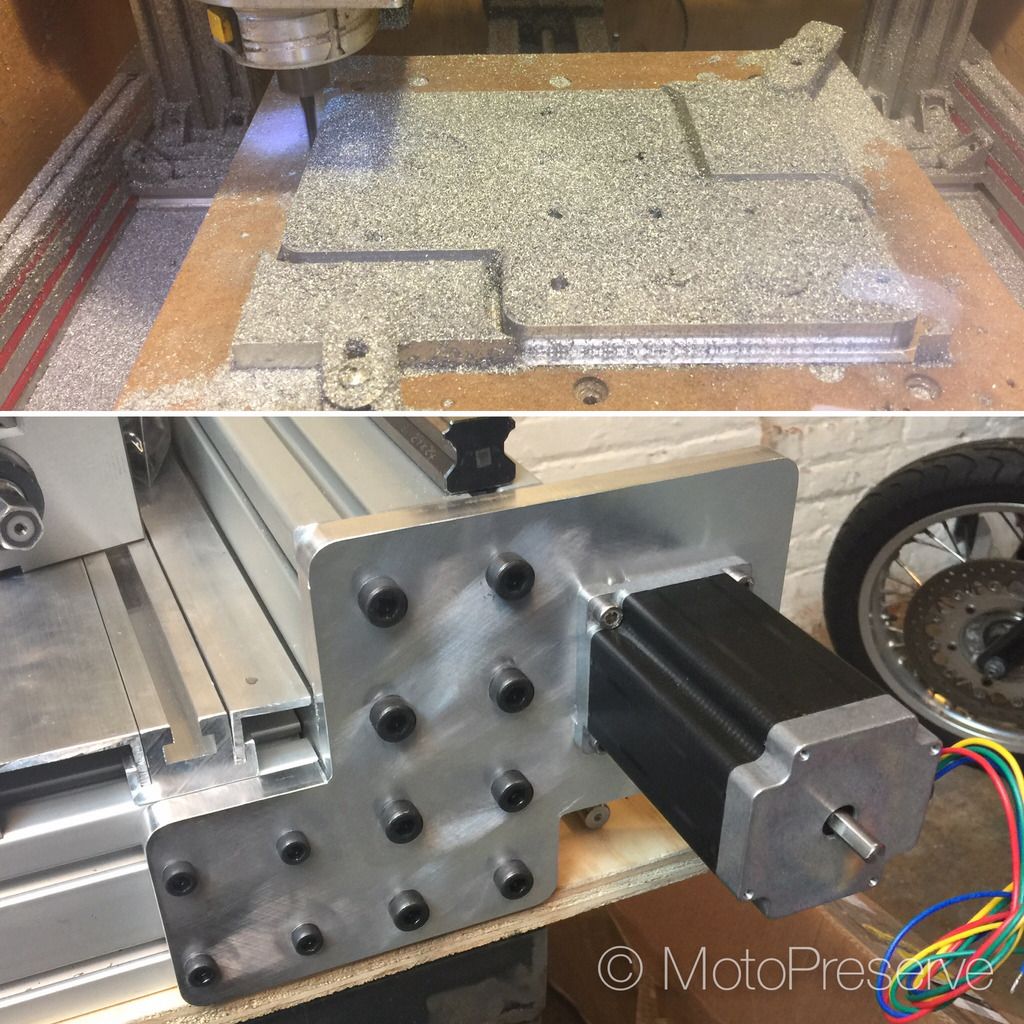

The gantry...

Starting to look like a machine...

- - - Updated - - -

Custom ballnut blocks...

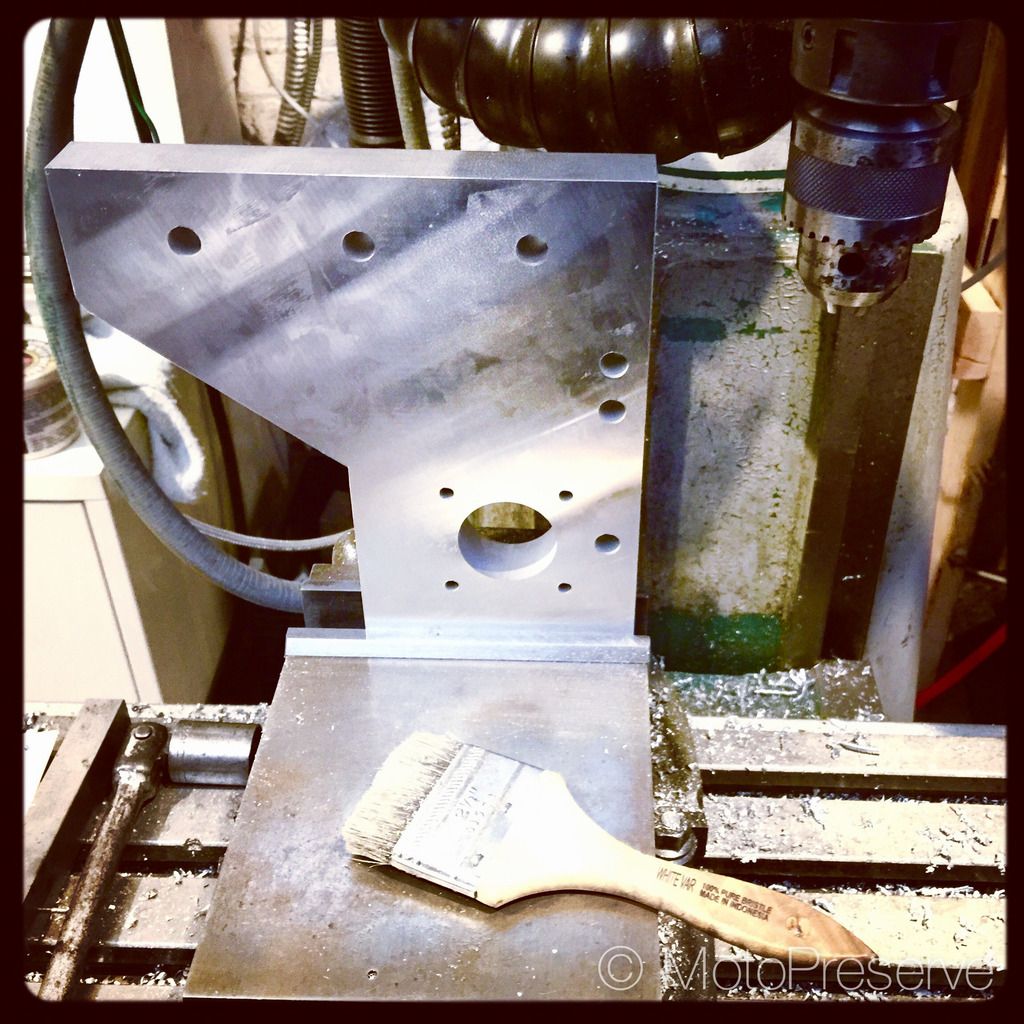

Making parts for the new CNC on the old CNC...

the little CNC worked well, but the vertical mill (Millrite) was priceless...

Results 1 to 19 of 19

-

06-15-2017, 02:27 AM #1

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

DIY Gantry-CNC heavily influenced by CNCzone...

-

06-15-2017, 02:55 AM #2

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

Re: DIY Gantry-CNC heavily influenced by CNCzone...

Cutting some of the first parts to roll off the new machine.... Taking it slow!

https://youtu.be/qO_lpGehLJ4

-

06-16-2017, 05:02 PM #3

Registered

Registered

- Join Date

- Aug 2006

- Posts

- 671

Re: DIY Gantry-CNC heavily influenced by CNCzone...

looks VERY sturdy. Well done.

-

06-16-2017, 06:24 PM #4

Registered

Registered

- Join Date

- Jun 2017

- Posts

- 12

Re: DIY Gantry-CNC heavily influenced by CNCzone...

I was looking at making one very similar to this design, do you have the links to where you sourced your parts / any of the CAD files you used to design this, I would love to get some inspiration from your really great machine!

-

06-17-2017, 01:35 AM #5

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

-

06-17-2017, 01:42 AM #6

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

Re: DIY Gantry-CNC heavily influenced by CNCzone...

Brian,

I got the ballscrews from the eBay seller "soloarjean" (many reviews here on the forums) who was really great to to deal with, and very accommodating with custom sizing. I realize that these Chinese screws are not the same quality that can be had with US/Japanese ground ballscrews, but the price for those was not in my budget. The aluminum profile was purchased from 80/20 on their discounted eBay store. All rails were purchased used, so no help there other than the advice to be patient and wait for your size/price to pop up and then pounce.

Let me know which parts you are still needing to source, and i will be happy to help if I can.

I do not have any of the CAD files online - but I may be able to send them to you if they would work with what you are looking to achieve.

Scott

-

06-17-2017, 01:46 AM #7

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

Re: DIY Gantry-CNC heavily influenced by CNCzone...

The machine at work today making a rear rack for a Triumph Tiger 800...

Today saw the addition of a Fogbuster unit. I am using Kool Mist for the cooling (and supposedly the new formula provides some lubrication). It's nice to have something better than just air blowing through Loc-Line, and occasionally spraying some WD-40 in the direction of the end mill - which was what had as a stopgap before this arrived.

https://youtu.be/yoRwas6VKuU

-

06-17-2017, 02:03 AM #8

Registered

Registered

- Join Date

- Jun 2017

- Posts

- 12

Re: DIY Gantry-CNC heavily influenced by CNCzone...

Thanks for the reply and all the info, but sadly I dont think any of these sellers are on Canadian Ebay, luckily I've found some good deals on Rails and Ballscrews on Ebay.ca. Since most my parts will be slightly different, I should probably CAD it on my own, I need some Solidworks experience anyways :P

As for general recommendations, do you recommend a VDF Spindle watercooled / air cooled? I was going to get a standard router such as a Dewalt 611, but after watching videos of how loud they are, Im concerned, and after watching your videos of your machine being very quiet (For a CNC Router) I might switch to a VDF, which is what it seems you have. Another quick question is what size is your build volume, and do you recommend a smaller build space for more rigidity? I dont exactly need more than 500mmx500mm, and if more makes a large rigidity difference than I might just stay there.

-

06-17-2017, 03:21 AM #9

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

Re: DIY Gantry-CNC heavily influenced by CNCzone...

More than anything, it really depends on what you plan to use the machine for cutting. I knew that I would be working almost exclusively on aluminum. While steel framing would have probably been best, aluminum extrusion/tooling plate offers me what I need in this machine.

If you are talking about a VFD with a spindle, then yes, I would recommend that route. My first small CNC ran the exact Dewalt router you mention - and while it was a great learning experience, it did not offer the variable RPM/flexibility that I wanted. And the water cooled versions, while adding complexity/cost (coolant pump) are much quieter.

I built the machine with an actual work area of about 20"x20" which was big enough for the plate I work with (and plenty big for multiple patterned small parts), while still small enough to maintain a level of rigidity. The smaller the better in that regard, except for the lack of mass. So I went the route of small machine/footprint - built as much like a brick sh*thouse as possible .

.

-

06-17-2017, 03:27 AM #10

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

-

01-11-2019, 03:51 PM #11

Registered

Registered

- Join Date

- Mar 2018

- Posts

- 70

Re: DIY Gantry-CNC heavily influenced by CNCzone...

Really nice build. Looks solid.

-

01-11-2019, 03:55 PM #12

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

-

01-11-2019, 05:56 PM #13

Registered

Registered

- Join Date

- Mar 2018

- Posts

- 70

Re: DIY Gantry-CNC heavily influenced by CNCzone...

It pretty much looks like the one I build at the moment:

Guess we both were inspired by this build:

How does your machine handle aluminium?

-

01-11-2019, 06:23 PM #14

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

Re: DIY Gantry-CNC heavily influenced by CNCzone...

Your design looks great! And familiar

Have you built it yet???

Have you built it yet???

That's definitely the build that inspired me most. About a year of researching other builds too - while waiting for decent linear rail prices in the correct sizes to pop up on eBay. But clearly my primary inspiration was his design.

Mine handles aluminum very well. That's basically all I cut with it - since the motorcycle parts I make are all aluminum.

The only issue I have not solved on my build is the bed. But I have been procrastinating a rebuild for a while now - because I have been successfully making parts. I've tried 2 different types of extruded aluminum for the bed and I have never been happy with it. The extruded aluminum seems to have resonant frequencies that I have wrestled with (coupled with the fact that rest of the build is not particularly heavy) - and have never found a way around that. No matter how I've secured it to the steel base, it has always seemed less than ideal.

I have been looking at old cast iron "surface plates" (or a variation usually listed as fixture tables) that typically come as a table. Occasionally they can be found as just the plate itself. They are pricey - but at this point, would be worth the rigidity and alleviating the hassles I've experienced with the extruded aluminum. I just need to source one locally (or close) that is the appropriate size, and then commit to the time to rework the machine to incorporate it.

-

01-11-2019, 06:52 PM #15

Registered

Registered

- Join Date

- Mar 2018

- Posts

- 70

Re: DIY Gantry-CNC heavily influenced by CNCzone...

If I had access to a larger cnc I would build a minimal steel base/bed. Something simple like this one:

Maybe in the future.

The Z and Y Axis with the slides are done. All that's missing is the X axis.

-

01-11-2019, 07:01 PM #16

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

Re: DIY Gantry-CNC heavily influenced by CNCzone...

That actually looks great - similar to what I have in mind. Won't be using a large CNC to do it though - just elbow grease and a healthy dose of frustration

-

01-17-2019, 06:03 PM #17

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 692

Re: DIY Gantry-CNC heavily influenced by CNCzone...

I've found a few cast iron surface plates on Craigslist for well under $1/lb. Typically far from lab grade, but especially if you've got a way to surface them (even if ridiculously slowly with a 1/4" bit,) they're still flat and pretty stout. I picked up an 18x24" recently for $60 or $70.

-

01-17-2019, 06:19 PM #18

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 23

Re: DIY Gantry-CNC heavily influenced by CNCzone...

Awesome machine. Very inspirational.

Where do you guys buy your heavy aluminum plate and then where do you have it cut/machined/drilled and how much does it cost on average, say, for a gantry side?

-

01-17-2019, 06:41 PM #19

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

Re: DIY Gantry-CNC heavily influenced by CNCzone...

I got most of my aluminum plate from an ebay seller called USA Metals Online. Nice guy in New Hampshire who sells off the drops from larger jobs. I just gave him a list of what I was looking for and then waited until he had the pieces to make up the order. I machined much of it myself, and then had some of the really large pieces cut by water jet. That was pricey - even though I was getting a "deal" from my neighbor.

Prices would likely be different now than when I bought it. You'd have to shop around to see what tooling plates are currently going for.

- - - Updated - - -

Unfortunately I have not been finding anything close to those prices. I'll keep looking though - eventually it will happen.

Similar Threads

-

Gantry mill with moving gantry for Z-axis

By rogue-insight in forum Vertical Mill, Lathe Project LogReplies: 25Last Post: 09-07-2020, 01:32 PM -

Heavily CNC converted Opti BF 20 Vario

By JMI80 in forum Benchtop MachinesReplies: 76Last Post: 04-15-2012, 02:34 PM -

Heavily vibrating motors when stationary.

By Gaz. in forum DIY CNC Router Table MachinesReplies: 3Last Post: 03-20-2011, 04:50 PM -

Gantry: planning to design moving open gantry

By rdcd in forum Mechanical Calculations/Engineering DesignReplies: 0Last Post: 11-14-2009, 10:52 PM

Reply With Quote

Reply With Quote