I know that servos are better at higher RPMs which when doing THC while cutting is NOT going to be high RPMs.

But most steppers are 2 phase and that is not very conducive to making .002" adjustments.

Not that money doesn't matter, but without taking costs into consideration which is preferred?

And can you connect shaft directly to a 5mm pitch ballscrew without a gearhead with either for this purpose?

Or have to at least rig up some type of pully system?

Results 1 to 9 of 9

-

09-18-2017, 11:39 PM #1

Registered

Registered

- Join Date

- Sep 2017

- Posts

- 5

Servo or Stepper for Torch Height?

-

09-19-2017, 01:48 AM #2

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 2415

Re: Servo or Stepper for Torch Height?

Most of that question is dependant on the THC you pick . You can easily get steps of .001 with a stepper and 5mm pitch leadscrew. 200 steps / 5 = 1000 steps per inch (not counting microstepping) You can get well over 100 IPM vertical motion IF your THC will handle that speed in the feedback loop. The other issue is the resolution of the THC . .002 change in height is only about ,2 volts change A lot of inexpensive THC's cannot hit more than 20 to 30 IPM without serious overshoot problems so having a fast servo is not going to help much.

-

09-19-2017, 02:04 AM #3

Registered

Registered

- Join Date

- Sep 2017

- Posts

- 5

-

09-19-2017, 10:30 AM #4

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Servo or Stepper for Torch Height?

With a light Z axis stage, 5mm ballscrew and a direct drive 269 Oz NEMA 23 stepper, I am getting over 250 ipm using Mesa hardware and LinuxCNC. In tests with a dial indicator, I got the acceleration up to about 100 inches/sec/sec without loosing steps (0.25 G's). However, in the real world I got a few crashes due to missing steps. I think the short, sharp acceleration movements stressed the motor more than the 50mm movements I made in my testing so I had to back off a bit. It is clear that acceleration is a key LinuxCNC THC tuning variable and upwards travel (when the weight is on the drive) is when steps are lost.

So in answer to your question, yes a stepper can do the job but...

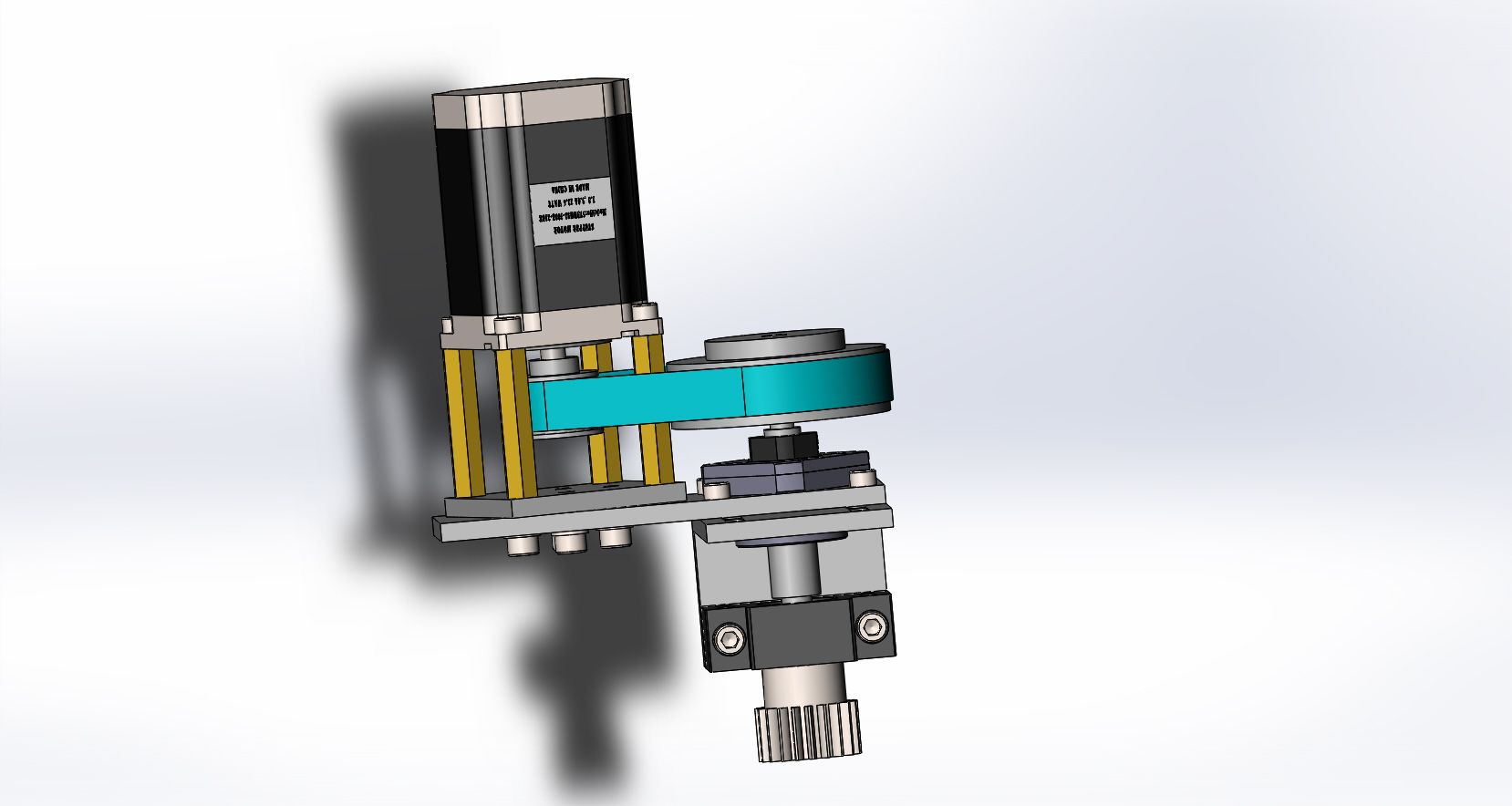

A little birdie told me that you might be using a 600 amp torch. If that is the case, your Z axis stage is probably quite a bit heavier than mine. I think that therefore the scales are tipped in favour of servos. I think this means that you will need a reduction drive. These are not hard to make if you have a lathe to make the shaft..This 3:1 design of mine works well for me and just bolts on where a NEMA 23 would and uses readily available bearing blocks. You might need 5:1 or better for a servo.

Rod Webster

Rod Webster

www.vehiclemods.net.au

-

09-19-2017, 03:17 PM #5

Registered

Registered

- Join Date

- Sep 2017

- Posts

- 5

Wow impressive! But... For the price of gearheads on eBay I think I would just go that route and not have the belt I need to worry about shielding. I need two though... But right now they have new 23s with 100:1 for $200... that might actually be too slow, and question how small the sprockets have to be inside there.

-

09-19-2017, 03:59 PM #6

Registered

Registered

- Join Date

- Mar 2017

- Posts

- 6

Re: Servo or Stepper for Torch Height?

I'm a oxy fuel cnc cutter operator. And the machine I'm using does just use ordinary dc motors connected to a ballscrew for torch heigth.

I can't see any advantage using anything more complex for torch heigth.. or am I missing something here?

-

09-19-2017, 07:49 PM #7

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 2415

Re: Servo or Stepper for Torch Height?

Yes, quite a bit. Plasma cutting is done at high feedrates (up to 350 IPM or more) and the Arc Gap (distance between the tip of the nozzle and the material needs to stay within .01 of the .06 cut height. Thinner metal warps and needs a fast Z response to avoid crashing the torch. A THC has to be able to pick less than a volt of change out of a signal that is over 100 Volts and rapidly changing. It forms a "servo" loop based on the fact the longer the arc the higher the voltage and the THC has to adjust the height mechanically fast enough to be able to close the loop and not have excessive overshoot. Compare that to cutting at 35 IPM and with a flame gap that can be 1/4" or more and has NO voltage for any feedback.

-

09-19-2017, 08:08 PM #8

Registered

Registered

- Join Date

- Mar 2017

- Posts

- 6

Re: Servo or Stepper for Torch Height?

My bad.. didn't catch that you are discussing a plasma torch... wish my company would upgrade to a plasma if you are getting 350ipm out of it, that's surprisingly fast! Must be on thin material tho..anyway, thanks for the information on plasma torch heigth control, interesting to know 😊

-

09-19-2017, 09:00 PM #9

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Servo or Stepper for Torch Height?

The drive is 3:1 (pulleys are 15:60 I think from memory). Will backlash on your gearboxes be a problem?

You may get away with the slower speed in your application. I'm guessing that you will be cutting thicker plate.

The other thing against you though will be acceleration.Rod Webster

www.vehiclemods.net.au

Similar Threads

-

Which Torch Height Controller for use with Ethernet Smooth Stepper

By Andrewcole in forum Plasma, EDM / Other similar machine Project LogReplies: 2Last Post: 11-25-2014, 10:56 AM -

How to set zero for torch height

By kxkid in forum CNC Plasma / Oxy Fuel Cutting MachinesReplies: 15Last Post: 08-10-2013, 01:41 PM -

Torch Height ?

By rtsplace in forum Hypertherm PlasmaReplies: 5Last Post: 04-03-2011, 09:09 PM -

torch height help

By marcmnrsports in forum Plasma, EDM / Other similar machine Project LogReplies: 0Last Post: 09-01-2008, 07:45 PM -

Building a plasma table...servo's or stepper's? (Torch head?)

By carbidecraters in forum Waterjet General TopicsReplies: 12Last Post: 06-23-2008, 06:11 PM

Reply With Quote

Reply With Quote