Full Re-Retrofit On My Blog...

I Somehow Obtained a Actual Tormach Lathe BOB for My Retrofit...

Everything is Going Well I Have Full Accurate Movement, I had to Change Some Proximity Sensors From PNP to NPN homing and limits e-stop all working as they should..

My goal "almost there" is that with Path Pilot just a couple small edits to the INI File and updating should be simple when the Tormach updates roll out as well as adding a Turret in the future.

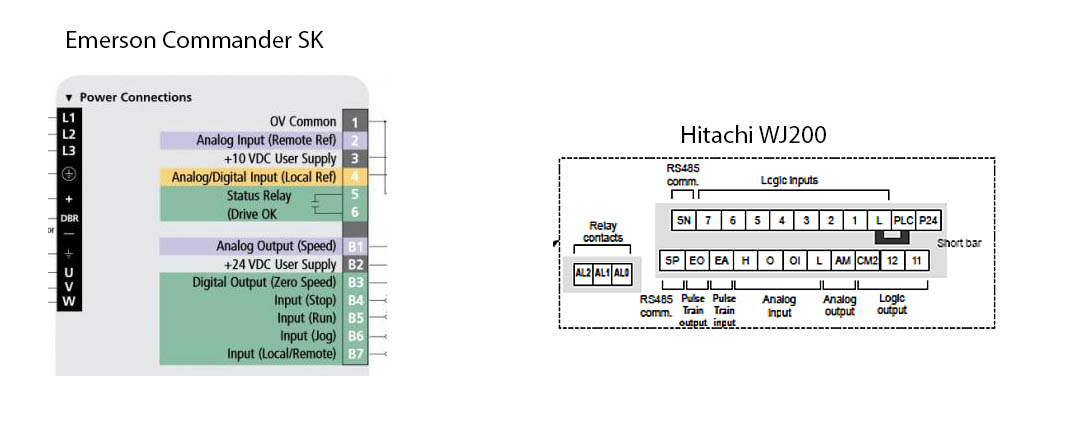

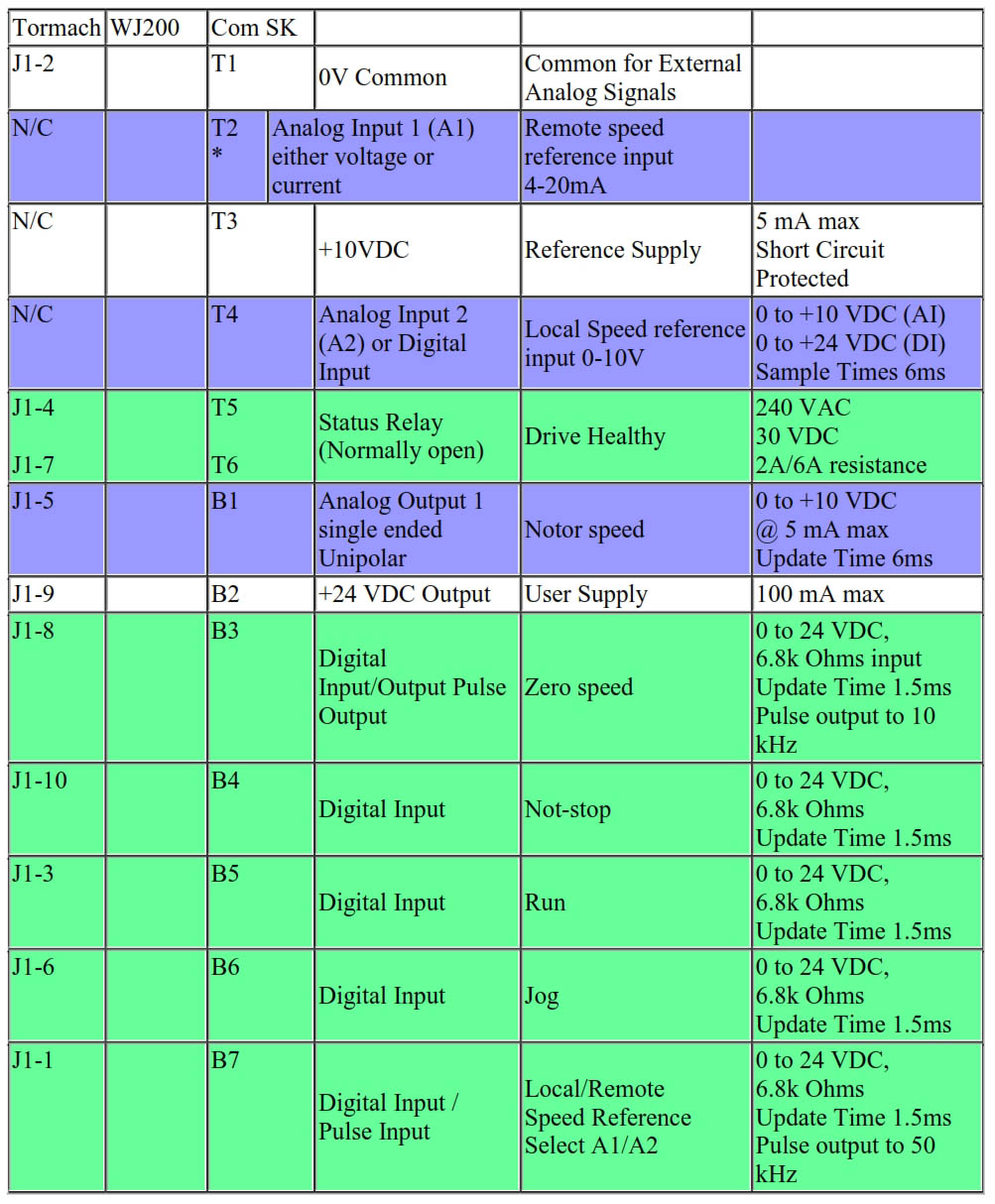

My Issue Right now is I Trying to Figure Out the VFD Configuration and Adapt to the Hitachi WJ200 to the Tormach BOB, Tormach Uses An Emerson Commander SK VFD.

The VFD Configuration is the next to the Last thing on my list for the Electrical Side.. Then after little over 3 years and multiple configurations I can Finally get things finished up.

Most the Connections Are Self Explanatory Hooking to the BOB Hitachi. Just trying to Figure How They are Using the Emerson I.O. for the Speed Control. (do not really want to assume and let the magic smoke out) It is hooked up on the lathe differently then the Mill or I would just go to my 1100 and pull the settings.

B1, B3, B7, On the Emerson Are In Question.

Ideal Help Would be to have someone with a Slant Lathe Pull Their Settings From The Emerson VFD for the I.O. (Thank You rdsi)

Manuals: SK Reference | SK Advanced | WJ200

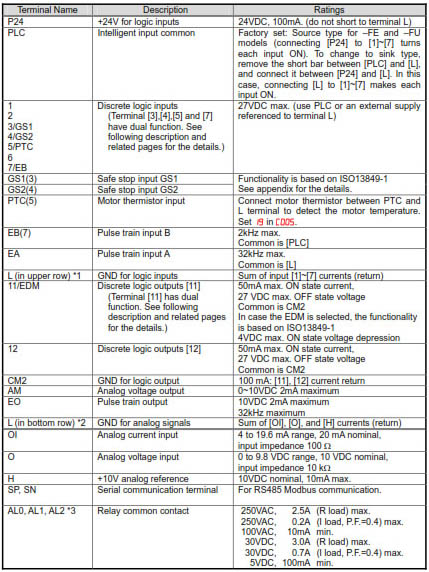

Emerson = Hitachi

T1 = L Lower

T5 & T6 = N/A (This is an E=Stop if Closed Prob Will set it to Normally Open Alarm Relay AL0-AL1 on the Hitachi.)

B1 = ? See Below (Will Assume Will Go to O on the Hitachi but could be EA also)

B2 = P24

B3 = ? See Below

B4 = N/A (Drive Enable Tied to B2 24V Pins 9 & 10 on BOB)

B5 = 1 (Forward)

B6 = 2 (Reverse)

B7 = ? See Below (Solved EA) Set WJ200 A001 Frequency Source to 06 Pulse.

From the Emerson Manual

B1 Analog Voltage Output - Motor speed

Voltage Output 0 to +10V

Scaling 0V represents 0Hz/rpm output +10V represents the value in Pr 02 Maximum set speed

Maximum output current 5mA

Resolution 0.1%

B1 Tormach Setting

A Voltage proportional to output current again not sure how to translate that to Hitachi WJ200 settings .

B3 Digital Output - Zero Speed (or Digital Input)

Voltage Range 0 to +24V

Maximum Output Current 50mA at +24V (current source)

B3 Function Tormach Settings

N=0 Zero Speed ??? How does that Translate to Hitachi WJ200 settings.

B7 Digital Input - Local/Remote Speed Reference

Logic Positive

Voltage range 0 to +24V

Nominal threshold voltage +10V

B7 Function Tormach Settings

Fr Frequency input Using Pulse Train Setting and EA On Hitachi WJ200

BOB to Emerson VFD

WJ200

Results 1 to 8 of 8

-

01-18-2018, 10:11 AM #1

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 234

PP 2.0 Lathe Retrofit V3 Now With a Tormach Lathe BOB. Hitachi WJ200 VFD Assistance.

Machines: Grizzly G0704 Mill W/ 3-Axis DRO | Birmingham 12X36 Lathe W/ CNC Retrofit PMDX-126/107 W/ESS 3ph W/ WJ200 VFD

-

01-18-2018, 01:49 PM #2

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 257

Re: PP 2.0 Lathe Retrofit V3 Now With a Tormach Lathe BOB. Hitachi WJ200 VFD Assistan

Find attached my notes on the subject...

I went through all the VFD settings & recorded them in the attached spreadsheet.

Also towards the bottom are my notes on wiring connections & motor dynamics.

On my machine the braking resistor was not enabled causing very slow deceleration.

It was so slow using the 3-jaw chuck that during CSS facing operations after retracting for the next cut it was still way over speed.

The highlighted parameters were changed in order to correct this.

I guess I have a column for my mill parameters in there too. Looks like I was going to move them into their own sheet but never go to it.

-

01-18-2018, 02:41 PM #3

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 234

Re: PP 2.0 Lathe Retrofit V3 Now With a Tormach Lathe BOB. Hitachi WJ200 VFD Assistan

rdsi thank you, thank you, this may help a whole bunch. I will check it out. Hope I can translate it to the WJ200.

Machines: Grizzly G0704 Mill W/ 3-Axis DRO | Birmingham 12X36 Lathe W/ CNC Retrofit PMDX-126/107 W/ESS 3ph W/ WJ200 VFD

-

01-18-2018, 05:45 PM #4

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 234

Re: PP 2.0 Lathe Retrofit V3 Now With a Tormach Lathe BOB. Hitachi WJ200 VFD Assistan

I have some spindle control now thanks rdsi.. just a small window about 5HZ will have to dive deeper in to the settings thanks a bunch. Got the ProDriveNext Software up and going now also.

Machines: Grizzly G0704 Mill W/ 3-Axis DRO | Birmingham 12X36 Lathe W/ CNC Retrofit PMDX-126/107 W/ESS 3ph W/ WJ200 VFD

-

01-20-2018, 01:55 AM #5

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 234

Re: PP 2.0 Lathe Retrofit V3 Now With a Tormach Lathe BOB. Hitachi WJ200 VFD Assistan

Still have not connected B1 & B3 due to deciphering language... but Changing Hitachi P055 Pulse Train Freq. Scale from Default 25 to around 2.9 gets me very active spindle movement wi change of spindle speed.. But not what it should be at 1000RPm may be getting 800 or 1200

Machines: Grizzly G0704 Mill W/ 3-Axis DRO | Birmingham 12X36 Lathe W/ CNC Retrofit PMDX-126/107 W/ESS 3ph W/ WJ200 VFD

-

03-30-2019, 11:16 PM #6

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 334

Re: PP 2.0 Lathe Retrofit V3 Now With a Tormach Lathe BOB. Hitachi WJ200 VFD Assistan

Hello Contract_Pilot

Can you identify the Large IC just to the left of PN 32574. Do you by chance have any high resolution images of this board?

Thanks,

Iron-Man

-

03-30-2019, 11:23 PM #7

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 234

Re: PP 2.0 Lathe Retrofit V3 Now With a Tormach Lathe BOB. Hitachi WJ200 VFD Assistan

PIC16F1947

Machines: Grizzly G0704 Mill W/ 3-Axis DRO | Birmingham 12X36 Lathe W/ CNC Retrofit PMDX-126/107 W/ESS 3ph W/ WJ200 VFD

-

03-31-2019, 02:19 AM #8

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 334

Re: PP 2.0 Lathe Retrofit V3 Now With a Tormach Lathe BOB. Hitachi WJ200 VFD Assistan

I noticed that J2 connects to the turret control board. The PIC has signals that terminate at J2.

The PIC has "Capture/Compare/PWM Peripherals 5 Input Capture, 2 CCP, 3 ECCP,"

I am almost certain that the PIC16F1947 is used to decode the PWM signals form PathPilot to control the turret.

Have you by chance tried to download the code on it?

Thanks,

Iron-Man

Similar Threads

-

Need Assistance Victor Lathe Fanuc series 20-TA

By Nweging in forum FanucReplies: 2Last Post: 07-24-2016, 08:05 AM -

Hitachi WJ200 Help

By szavoda in forum Spindles / VFDReplies: 1Last Post: 10-03-2015, 12:05 PM -

New Mill and Lathe purchase assistance needed

By InfernoST in forum Want To Buy...Need help!Replies: 0Last Post: 07-03-2015, 02:08 PM -

New lathe owner .need assistance

By chrisnis in forum Mini LatheReplies: 8Last Post: 10-20-2012, 04:35 PM -

Need Lathe assistance ASAP please

By Sigma1 in forum MastercamReplies: 11Last Post: 08-30-2012, 02:05 AM

Reply With Quote

Reply With Quote