This would be my first attempt at building/designing any kind of cnc machine.

I'm building my macnine based on what i want it to do, but i'm using alot of ideas of Greolt's ideas from his "another aussie router". Pretty much most of design is based of his machine.

Macnine will is going to be aluminum with 3" channel frame, Bosch Rexroth rails, Rack and Pinion Drive (dual on x) and normal on y. Z will use lead screw.

I'm expecting to get 28"x20"x6" cutting area. Over all frame size is 1000mm x840mm.

My goal is to spend under $1500. So far everything is looks like i will make it just under that mark.

Gantry will be made of 3/4" aluminum bar. Mostly 6" wide. Some of the aluminum was free, so it saves quite a bit of cost.

Here are few pics of frame welded. Also drilled and tapped holes for one of the rails today.

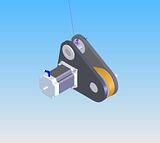

Here are few bits for Z axis:

I still havent decided on what electronics/motors to use, i was thinking keling 4 axis 425 oz-in set, but still not sure. Really would like gecko's but thats too expensive at the moment, maybe on next machine. So any suggestions are welcome.

Gear racks havent been ordered yet, waiting on rails to be mounted, also not sure how i'm going to make the bracket(design wise). Most likely it will be reduced to 5:1. Also suggestion are welcome on this.

Here is quick sketch of what i want it to look like:

Thread: Started new project

Results 1 to 20 of 56

-

04-05-2007, 04:05 AM #1

Started new project

-

04-05-2007, 04:10 AM #2

i also need suggestion on what spindle to use for aluminum cutting. I was planing on getting Hitachi router for wood, but wasnt sure how aluminum liked it. I would like to desice now so i can start looking for deal and have it by the time machine is finished(hopully two weeks

)

)

-

04-05-2007, 11:39 PM #3

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1673

Hi,

I like your design; nice clean and simple; looks like it will work real nice.

Could I ask why you have decided on dual Rack and Pinion on your X axis? Would it not be far simpler to use a screw or pair of screws? I have never looked in to rack and pinion myself and am wondering what kind of resolution you will get?

As for 425 oz in motors; they will be plenty for a small machine especially if you use reduction. I would think around 250 oz in would give you as much power as you needed but get more opinions on that. Will the drives give you full torque using them bipolar parallel (twice the Amps rating of the motor)? You may need the extra speed if you are going to cut wood.

As for a spindle for aluminium; you may be fine with the Hitachi and cutters designed for cutting aluminium to be used in a router spindle. How many Watts/horse power is the Hitachi? I have very nearly finished my new machine and will be having a go milling aluminium also. Will be doing research on cutter and methods here so maybe we can share what we learn.

Hopefully there will be more input into your thread regarding machining aluminium with a router spindle and we can both save just using a router instead. If any one passes through and knows any good links to threads discussing milling aluminium with a router could you please post them here?

Best of luck (we all need some sometimes) with the rest of your build and I hope you keep posting here to let me/us know how you get on.

John

-

04-08-2007, 01:14 AM #4

Here are few more pic's of progress. Got the aluminum for gantry yeasterday, had it milled square and parallel this morning, and started on drilling/tapping the main big peice. Finished tapping all the holes for rails. Will order gear rack and pulleys on monday.

As for the reason i decided on R&P, no real reason, i just really like greolts design, and seen some videos of R&P routers, and really liked it, so thats what i'm doing.

-

04-09-2007, 04:55 AM #5

I'm getting ready to order some gear rack, but I'm not familiar with all the terms/dim. Could anyone recoment what to order? I was looking to order from these guys: stdsteel.com Any suggestions would be very welcome.

Also picked up Hitachi router at lowes today, got it for $108 with tax. More work will be done tommorow(Monday).

Also going to order timing belt/pulleys, need to do some calculations about that as well...

Kelling 4 axis kit is on order as well, hopefully will be here tommorow or tuesday, so i can play around with it before put it on the machine :wee:

-

04-09-2007, 04:58 AM #6

Here are the specs on Hitachi router:

Horsepower: 2-1/4

Amps: 11

No-Load Speed (RPM): 8,000 - 24,000

Depth Capability: 2.6"

Type: Fixed

Max Collet Capacity: 1/2" and 1/4"

Weight: 7.3 lbs.

-

04-10-2007, 11:35 PM #7

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

G'day Russ

Looking good so far.

In your sketch where is your table going?

Using the flat plate as your main section on the gantry I am concerned about how far your cutting tool is going to hang below the gantry.

Cutting forces will have a greater twisting action (engineers have proper names ) on the gantry, the further the tool extends down.

) on the gantry, the further the tool extends down.

My idea is to design the Z axis so that the longest tool will raise to the level of the lowest part of the gantry.

Combined with keeping the gantry as low as possible to give the clearance you desire.

Hope that makes sense. Keep up the good work

Greg

-

04-10-2007, 11:52 PM #8

How much flex do you think I would get with 19mm plate? Would it be very significant?

-

04-11-2007, 12:55 AM #9

-

04-11-2007, 01:08 AM #10

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Russ I'm not smart enough to work that out.

Just know the more leverage the cutting forces have the more it must flex.

Hence my penchant for keeping things close.

I'm not suggesting making a Z axis travel you are not happy with.

Only to make the tool no further from the gantry than it needs to be to get that travel.

Keep it close = keep it rigid.

Greg

-

04-11-2007, 08:09 PM #11

-

06-18-2007, 12:23 AM #12

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Hey Rustamd. How's it going?

Any progress to show? How about some more pics.

Greg

-

06-18-2007, 04:02 AM #13

I have been meaning to update this thread, thank you for making me do it

.

.

My original gantry design changed as I messed up the side peices of the gantry, so I just used the shorter peices that I had laying around(by 2"). This should make it sturdier(sp?), at least a little bit. After i bolted the gantry together everything was very firm and solid, didnt feel any play, or wasnt able to fell any racking, but have not measure anything yet either.

Here is gantry sitting on frame, without rails:

-

06-18-2007, 04:03 AM #14

-

06-18-2007, 04:09 AM #15

than i mounted the gantry to the rails on X axis. Also surfaced the frame becouse it was slightly 'toe in"(not sure how to explain this better) No picture of gantry on rails

. But i ran in into slight problem that I didnt realise that i had, i was not able to bold liniar truck to the gantry, it interfered with other bolts. Few minutes on the mill fixed that

. But i ran in into slight problem that I didnt realise that i had, i was not able to bold liniar truck to the gantry, it interfered with other bolts. Few minutes on the mill fixed that  .

.

-

06-18-2007, 04:12 AM #16

also mounted the Y axis rails on the gantry that same day, no clear pictures of this, but you can see it slightly in first picture up there:withstupi

-

06-18-2007, 04:16 AM #17

-

06-18-2007, 04:18 AM #18

-

06-18-2007, 04:22 AM #19

-

06-18-2007, 04:28 AM #20

Similar Threads

-

getting started

By richaevans in forum CNC Wood Router Project LogReplies: 2Last Post: 08-21-2006, 04:34 PM -

getting started

By richaevans in forum CNC Wood Router Project LogReplies: 1Last Post: 08-18-2006, 08:20 PM -

Finally Started My Router Project

By Ozinus in forum CNC Wood Router Project LogReplies: 19Last Post: 07-18-2005, 11:46 PM -

Getting Started

By PaulSwany in forum DIY CNC Router Table MachinesReplies: 8Last Post: 04-13-2004, 10:25 PM -

If you were to just get started.

By rustranch in forum DIY CNC Router Table MachinesReplies: 6Last Post: 09-24-2003, 03:11 PM

Reply With Quote

Reply With Quote