Hi all,

I'm documenting my build on my website Barber Precision but I thought I'd also have a build thread here so I can get feedback or ask questions.

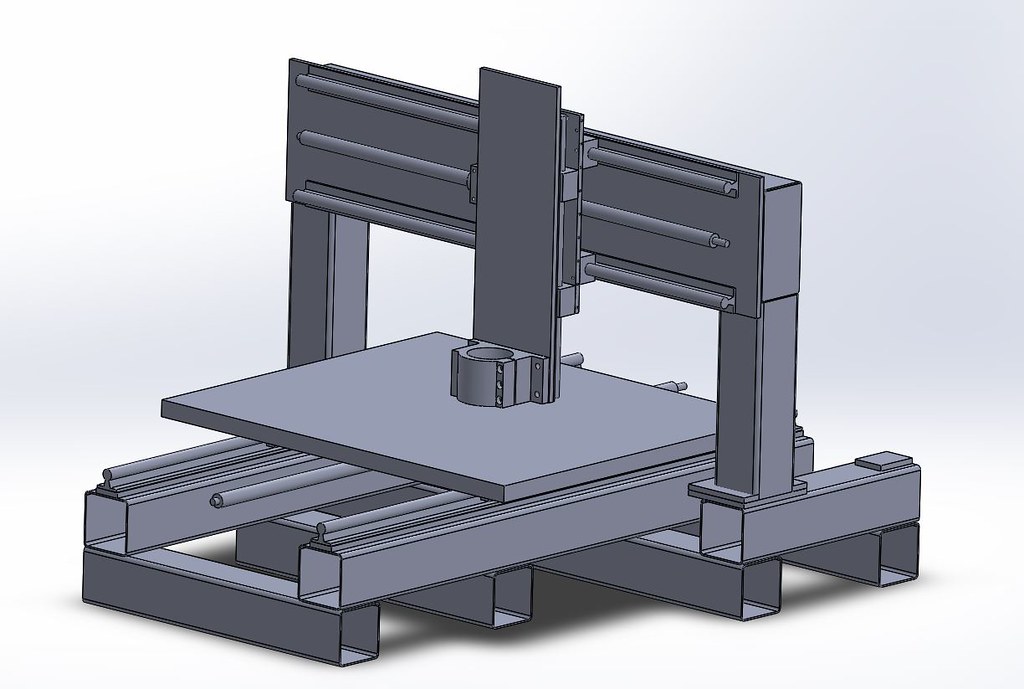

I've built a CNC plasma cutter before which turned out really good but I feel a router capable of machining aluminium will be more useful for the sort of projects I plan on doing.

I've been working on the design on and off for some time and finally got it to the stage where I'm happy to begin construction.

Before anyone mentions it, the gantry IS going to have back stays which go to the plates at the rear of the machine - I just haven't put them in the model yet. The Z axis setup is also slightly modified from this as-well. I'll get a snapshot of the changes tomorrow.

Many of the design choices revolve around ease of manufacture with the tools I have available, and budget constraints (round rail vs profile rail). I've designed the machine to be easily upgradeable to profile rails at a later date, and to have the surfaces on which the rails are mounted easily machined/ground perfectly flat at the same time.

The main frame is 100 x 100 x 3 tubing with 50x10 flatbar welded where the rails go, again so they can be machined flat at a later date if necessary and to provide material to tap threads.

The main gantry piece is 200 x 100 x 6 RHS with a 250 x 10 flatbar welded onto the front face. This will allow easy mounting of any sort of rail, and the 10-16mm material will be plenty for holding strong threads.

I stitch welded the flatbar onto the RHS to minimise warping - I believe it will be fine, but if there are any issues it's a simple matter to fully weld the piece on.

The end caps are welded on

And then the legs were attached.

So far I have about 2 hours work in the gantry and it still needs holes drilled and tapped for the linear rails. Once that's done I can attach the feet and start putting together the y/z axis. I might make the base frame last because it's all going to be pretty heavy once it's all put together. I'd estimate the gantry weighs about 50kg already!

Currently the Y and Z axis pieces are going to be 10mm aluminium plate because that's what i have available. I'll put stiffener plates on either side and possibly in the middle to gain some rigidity, but if I end up upgrading to profile rails I'll go with 16mm or 20mm if I can get it.

Any and all feedback on the design is welcome. If I haven't made it yet I'm happy to modify the design if anyone can spot anything that could be improved!

Thread: Welded steel frame router build

Results 1 to 20 of 95

Threaded View

-

08-30-2018, 12:32 PM #1

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 73

Welded steel frame router build

Similar Threads

-

Steel Frame Router Build

By trailerparkboys in forum CNC Wood Router Project LogReplies: 1Last Post: 03-08-2016, 01:53 PM -

Steel frame Ganrty router build

By matth in forum CNC Wood Router Project LogReplies: 172Last Post: 10-30-2014, 08:32 PM -

My First All Welded Steel Router Design

By widgitmaster in forum CNC Wood Router Project LogReplies: 9Last Post: 10-18-2008, 03:07 PM

Reply With Quote

Reply With Quote