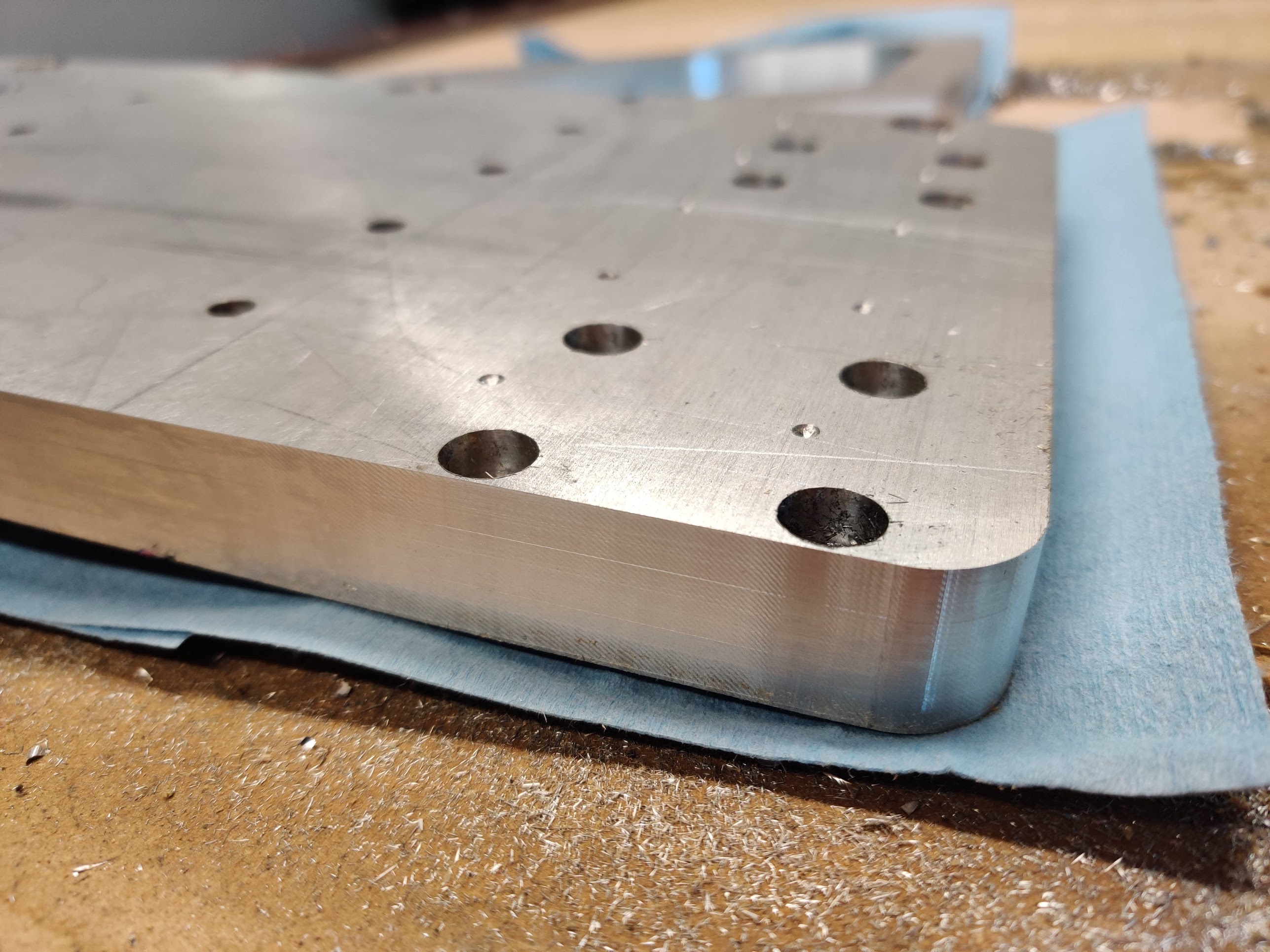

here is what I was cutting today and the basic setup I used.

Don't be deceived by the finish on the side, it is smooth to the touch. And the cut edges are razor sharp, just need to deburr all of them.

Results 21 to 40 of 99

-

08-04-2019, 10:52 PM #21

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

-

08-04-2019, 11:44 PM #22

Member

Member

- Join Date

- Sep 2005

- Posts

- 1740

Re: CRP4896 Standard to Linear Rail Conversion

I don't know if you have a Goodwill store or the like, or even new it would be cheaper than $300. Buy an aluminum cookie sheet (with lips) and screw down at the edges with sheet metal screws and silicone sealer. Place your work piece inside that and go for it. When done either toss toss the sheet or save, you decide. Not perfect but Fast and cheap.

The MDF could be easily sealed.Retired Master Electrician, HVAC/R Commercial. FLA Saturn 2 4x4 CNC Router Mach4 Kimber 1911 45ACP

-

08-04-2019, 11:51 PM #23

Member

Member

- Join Date

- Sep 2005

- Posts

- 1740

-

08-05-2019, 12:36 AM #24

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

wmgeorge the cookie sheet is a good idea!

-

08-05-2019, 12:47 AM #25

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

Re: CRP4896 Standard to Linear Rail Conversion

Thank you for sharing. Given the sizes of the pieces you milled vs the size of the MDF, I'm surprised to see the moisture contained so well. On my mill, wet chips seem to go everywhere. But then, what I cut on my mill is elevated above the table in a vise. I'm sure the elevation ensures chips get thrown farther.

Nothing deceiving about the edge. It looks smooth to me. No obvious chatter.

I recognize the lower plate. It's the plate that mounts on the X axis linear rails to which the Z axis mounts. The upper plate looks like the horizontal one that mounts to the lower plate in your photo and is the one the stepper driver mounts on.

Just curious, but what linear rails are you using? I used Hiwin 25mm (Avid uses 20mm) for the Y axis and Hiwin 20mm for the X. The Hiwin bearing blocks for the 20mm rails have the same mounting hole spacing as the ones Avid uses. I used a medium preload vs Avid's light preload, which I'm very happy with. Medium is hard to find in the Hiwin copies, but are readily available in Hiwin. If you haven't purchased your linear rails yet, you might take a look at this company. https://motionconstrained.com/ The prices are as good as I've found for Hiwin, and the service is great. The parts arrived in perfect condition.

I'm thinking HDPE or UHMW might be a reasonable substitute for MDF, being waterproof and all. However, given the cost, zeroing the cutter to the surface of the HDPE would be essential. Seeing your setup stimulated some ideas.

Thank you again.

Gary

-

08-05-2019, 12:54 AM #26

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

So I do not notice the chips that get sent flying having a noticable amount of liquid on them. The coolant seems to stay confined to the surface of the part, I only had so much water flow off because I was having some issues with air bubbles and had to crank up the coolant to get flow.

The coolant only seems to effect a small area near the surface of the cut MDF, it does not "soak" into the entire MDF.

If I was going to be doing a huge amount of machining of the same part I would totally go for a UHMW or HDPE fixture plat with troughs to catch any coolant.

I would love to find a cheap source of plastic sheet.

I have not yet purchased my rails, I have been considering the automationoverstock BLH rails, Kent at automationoverstock/automation4less says they are very good.

wmgeorge, you are welcome on the picture of the mist coolant system. It works well, in 3 hours of cutting with way to much fluid flow I managed to drain about 1/2 of the coolant compared to the picture I posted here.

-

08-05-2019, 01:24 AM #27

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Prices of what I need.

-

08-05-2019, 03:52 AM #28

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

Re: CRP4896 Standard to Linear Rail Conversion

Me too. The cost of the stuff is almost obscene. Ditto for aluminum plate and cast aluminum.

If they are as good as Hiwin, it's a great buy. I'm impressed by the fact you can get medium preload. As far as I can tell, pretty rare in Chinese built linear motion carriages. I hope the BLH works out for you.

Gary

-

08-05-2019, 04:30 AM #29

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Gary, I am going to give them a try, gamble the $880.....

I bought my .750 6061 thru my work, so got about a 25% savings over retail.

-

08-05-2019, 05:04 AM #30

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

Re: CRP4896 Standard to Linear Rail Conversion

I'm green with envy.

I'm retired now, but never worked anyplace where I could buy metal or plastics through work. I used to be able to buy lots of the good stuff from Boeing Surplus brick & mortar store in the Seattle, WA area. Steel was $.25/pound. Aluminum was around $1/pound. I don't recall about plastics, but the price was similar. Essentially, I was able to buy for scrap price. That was years ago. I spent many Saturdays there. It was an adult's toy store.

I'm retired now, but never worked anyplace where I could buy metal or plastics through work. I used to be able to buy lots of the good stuff from Boeing Surplus brick & mortar store in the Seattle, WA area. Steel was $.25/pound. Aluminum was around $1/pound. I don't recall about plastics, but the price was similar. Essentially, I was able to buy for scrap price. That was years ago. I spent many Saturdays there. It was an adult's toy store.

Boeing closed the store and now has an online presence. Rather than having thousands (sometimes 10s of thousands) of items for sale at any given time, the online store, which operates as an auction, only has a few things at a time, and frequently in larger lots. There are still deals to be had, but you have to keep on top of it. Also, you have to live in the area, unless it's worth coming to the Seattle area to pick up. They don't ship.

Gary

-

08-05-2019, 06:00 AM #31

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

I once got the chance to go to the Boeing Surplus store in Kent, it was fantastic..... so sad when it closed.

I live down in the Portland area.

-

08-05-2019, 01:44 PM #32

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: CRP4896 Standard to Linear Rail Conversion

Be prepared for a $200 shipping charge.Gary, I am going to give them a try, gamble the $880.....

Shipping on my 3000mm rails was $170 a few years ago.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

08-06-2019, 01:30 AM #33

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Well I would be paying that $200 weather I was getting Hiwin or BLH.

-

08-06-2019, 05:39 AM #34

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

-

08-06-2019, 03:18 PM #35

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Gary, I looked at Motion Constrained, they are more then $200 higher then Automation4less for Hiwin.

But as I said, i am going to take a gamble on the BLH rail from automationoverstock, kent swears they are good and several US equipment manufacturers are using them. He for obvious reasons will not share the name of those OEMs.

-

08-07-2019, 01:15 AM #36

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

Re: CRP4896 Standard to Linear Rail Conversion

How odd. When I bought my stuff, I compared Automation4Less to Motion Constrained. Motion Constrained was hugely cheaper.

I just did a price comparison on my HG 25mm for my Y axis.

Automation4Less

Rails (1660mm)= $297.97 X 2 = $595.94

Bearing Blocks= 4 X $67.64 = $270.56

Total = $866.50

Same from Motion Constrained = $526.22

I stopped there. Just my Y axis was $340 cheaper.

Don't get me wrong. I'm not pushing one brand over another. I'm sure the BLH will work fine. Avid uses generic Chinese rails and has plenty of happy customers. The odds are good that yours will be at least as good as the ones Avid uses, and may even be better.

Gary

-

08-07-2019, 02:00 AM #37

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Gary, I must have been looking in the wrong place. I would also have to cut rail. Let me look again.

Found it, i was in the complete linear guide section, not the rail and blocks section.

But still not as cheap as the BLH rail.

-

08-08-2019, 05:33 AM #38

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Commited now, ordered the BLH rail. Only $52.80 in shipping cost.

-

08-08-2019, 06:03 PM #39

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

Re: CRP4896 Standard to Linear Rail Conversion

Do you plan to use the Avid technique for aligning your new rails, or do you have an alternate plan in mind? I'm anxious to see how it goes. Linear rails have a reputation for being difficult to install on extrusion-based machines. Avid's technique (with the positioning jig) is okay, I suppose, but its success is dependent upon the rails being 100% straight and everything being coplanar. There is no straightness tolerance for rails that I have ever found, so relying on a jig alone may not produce a perfect result. Did you use a machinist level when you constructed your machine to ensure all was level and coplanar? If not, I'm thinking you could have issues. Also, because your Y axis rails are mounted on the sides (versus mine on top} you may have an interesting adventure getting them installed to a fairly exacting tolerance. I'm sure there are a number of folks who will be interested in seeing how you manage it all - myself included.

Good price on shipping. Free is better, but $52.80 is pretty darned good, especially given the length of your Y axis rails. As I understand it, when when the parcel size gets over 108" in length, the shipping cost goes up - at least for UPS shipments. Sounds like you got a good deal all around.

Gary

-

08-09-2019, 01:47 AM #40

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

I did not use a machinist level to level the machine.

As far as I can tell the tops of my rail are as flat as I can possibly make them.

I was going to use a modified version of AvidCNCs install method, but not just from the ends. I was also going to hit a few places in the middle with the clamping fixture before tightening the rest of the screws.

Similar Threads

-

HF 8x14 linear rail conversion....and maybe more...

By CS900 in forum Mini LatheReplies: 99Last Post: 08-10-2022, 02:12 PM -

Standard linear motion conversion to linear rails.

By bobmagnuson in forum Avid CNCReplies: 11Last Post: 03-25-2022, 09:52 PM -

G0704 Linear Rail Conversion

By BTP in forum Benchtop MachinesReplies: 63Last Post: 07-14-2019, 01:59 AM -

Sieg X3/SX3 Linear rail conversion

By DvG4 in forum Benchtop MachinesReplies: 1Last Post: 01-16-2011, 02:17 AM -

Mixing Preloaded&Standard linear trucks on same rail -pros and cons ?

By isvflorin in forum Linear and Rotary MotionReplies: 2Last Post: 01-13-2009, 06:05 PM

Reply With Quote

Reply With Quote