All the parts are off to anodizing. All the components for assembly have arrived. So assembly starts when the parts get back!

Results 61 to 80 of 99

-

09-15-2019, 03:17 AM #61

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

-

09-15-2019, 10:21 PM #62

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

-

09-24-2019, 05:19 AM #63

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Parts are back from anodizing..... BLING!

-

09-25-2019, 05:09 AM #64

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

Re: CRP4896 Standard to Linear Rail Conversion

Bling indeed. Very nice. The texturing looks great!

Gary

-

09-25-2019, 05:39 AM #65

-

09-29-2019, 01:41 AM #66

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Disassembly complete!

Before -

After -

-

10-05-2019, 01:31 AM #67

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

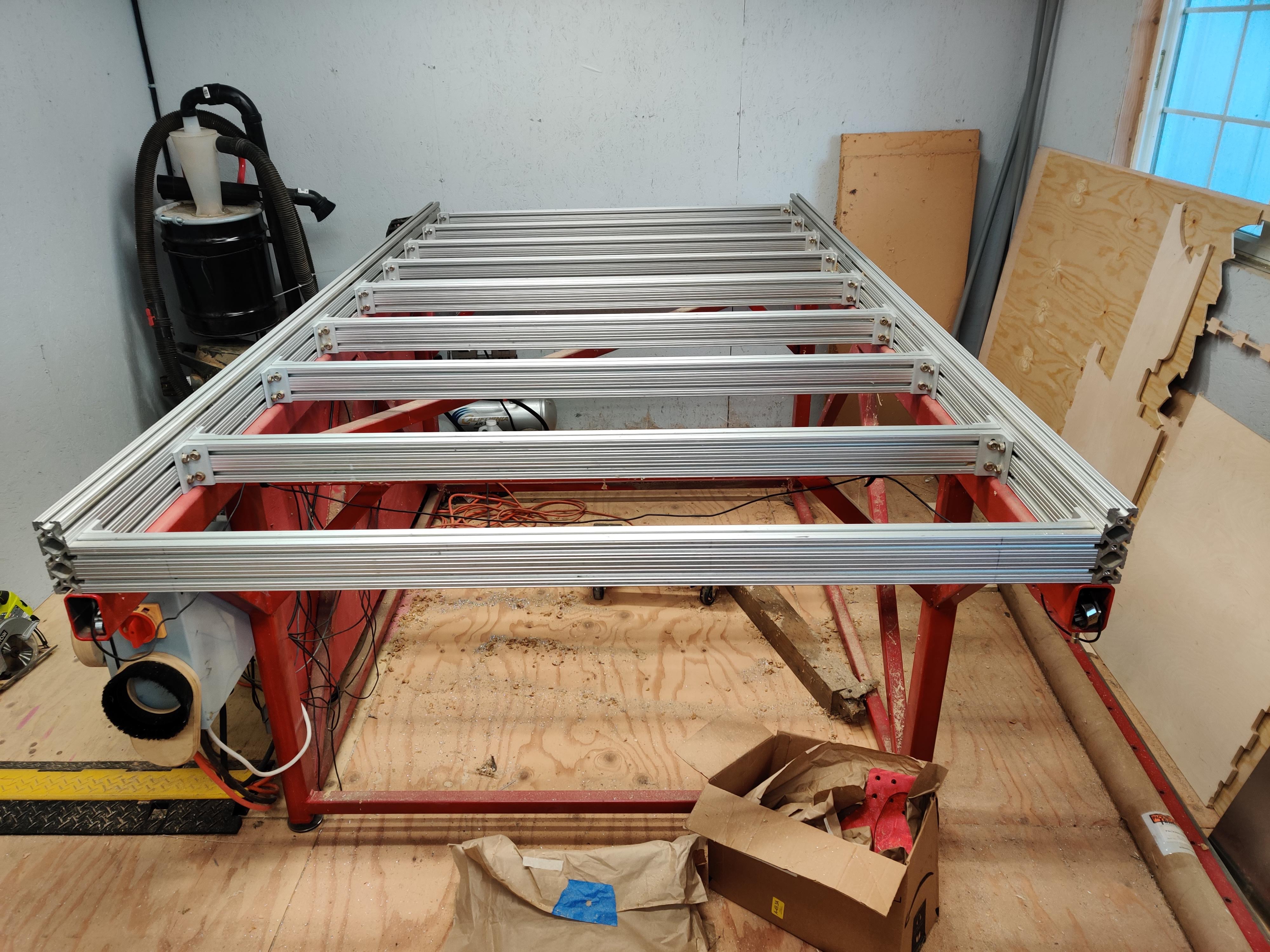

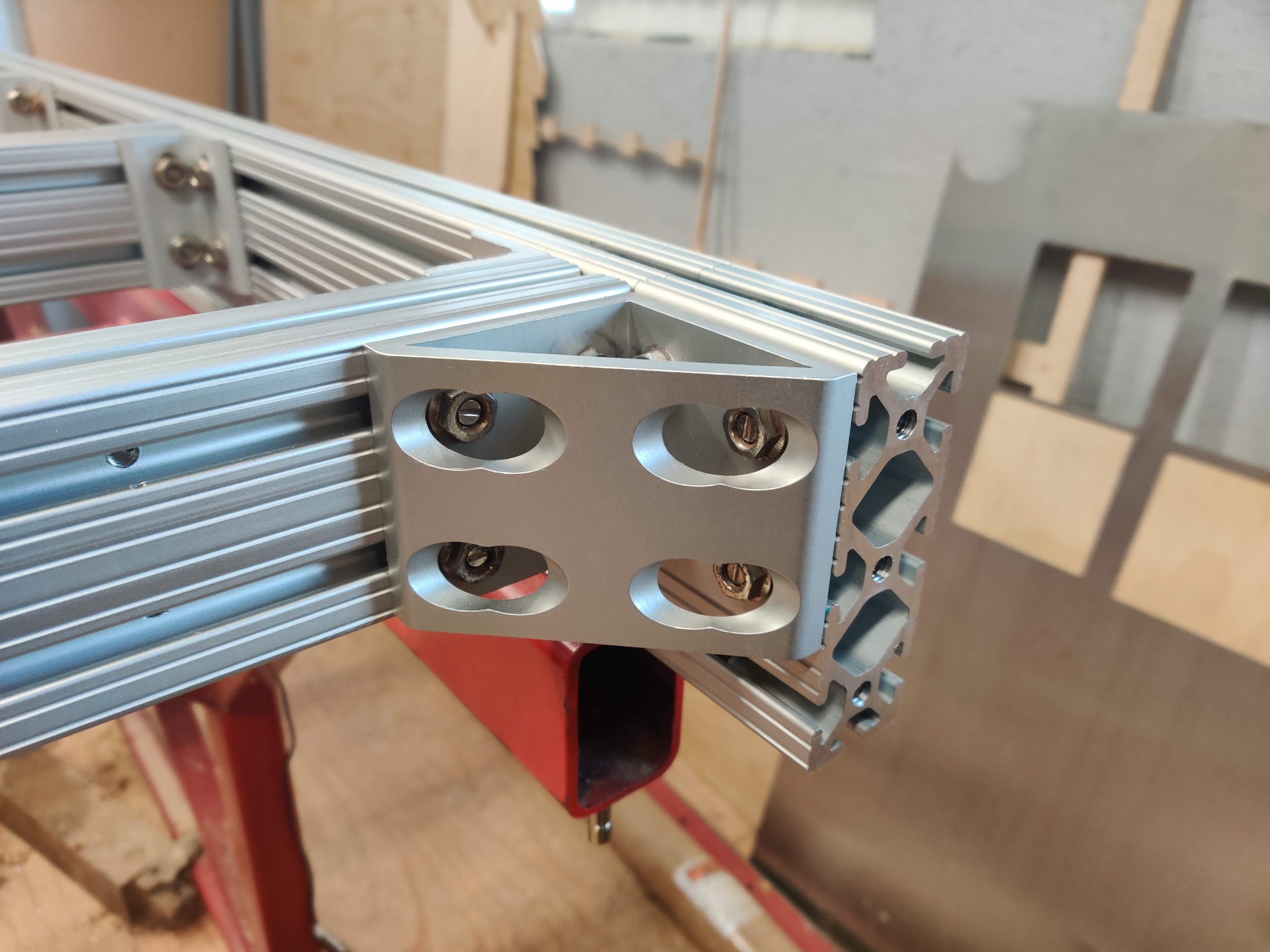

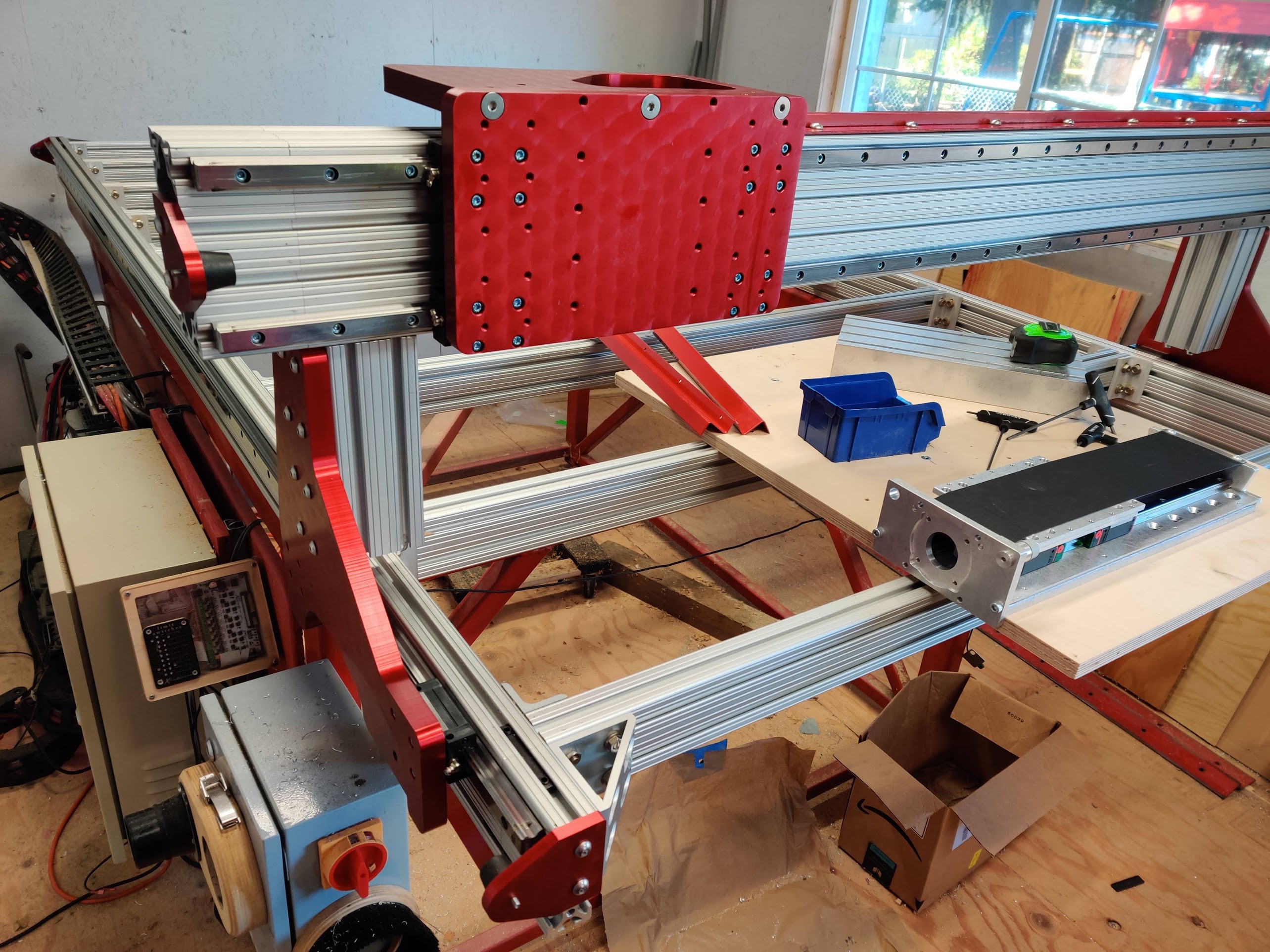

started reassembly today.

Flipped the extrusion table over, so that all the beams are level at the top.

Installed the extrusion extensions, these are on all 4 corners to get me a 12 inches of separation on the linear carriages on the y-axis.

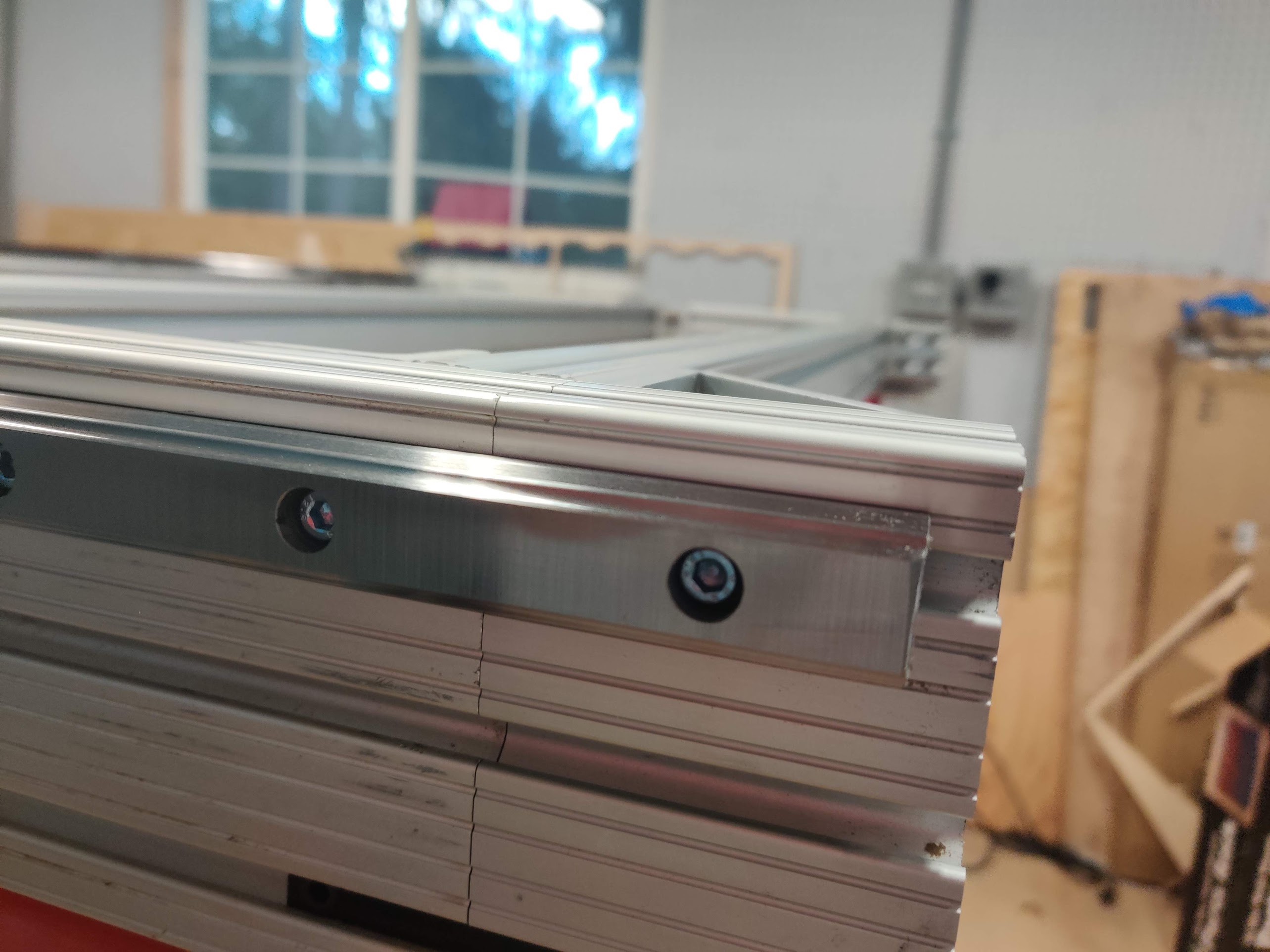

Installed both y-axis linear rails, these are BLH linear rail from automation overstock, they do appear to be ground quite nicely on the actual ball surfaces. But the top and bottom surfaces do have what appears to be a very course sanding/grinding applied to them, smooth to the touch but with noticeable lines in it. I did temporarily install one carriage and it ran smooth with no grinding or even making very much noise either.

-

10-06-2019, 11:23 PM #68

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

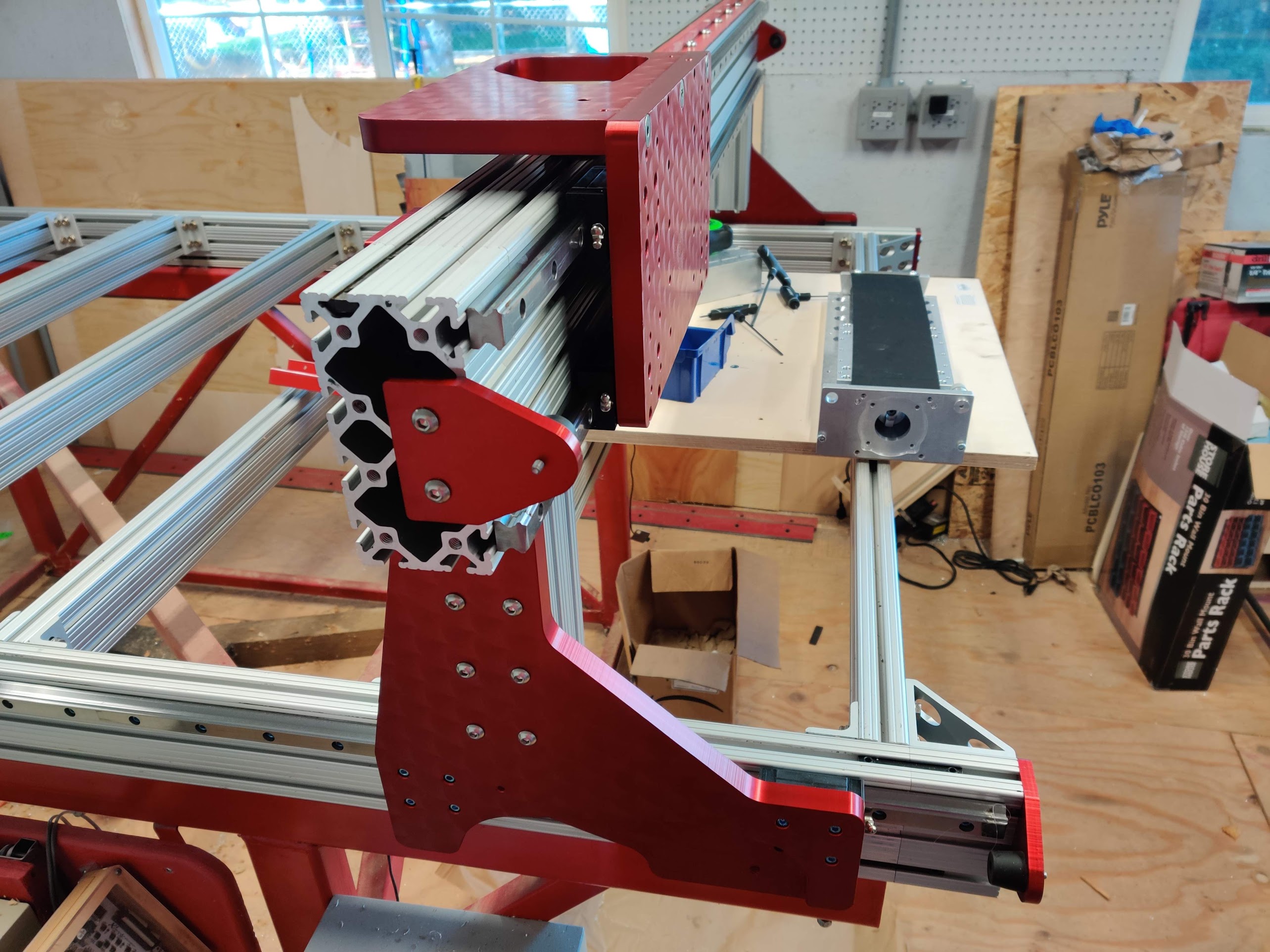

So this weekend got the rails and gantry assembled.

And then ran into a problem, somehow I ended up with my z-axis bolt pattern 5 inches wide, but the actual pattern is only about 4.75inches wide.... no idea how I managed this, working a couple options to fix it.

-

10-07-2019, 05:19 PM #69

-

10-08-2019, 05:12 AM #70

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

the pad holder was just a good flat holder, 1/4 shaft.

Here were the pads I used, https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

-

10-11-2019, 10:13 PM #71

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

An aquaintance helped me mod the z-axis mounting plate. We just drilled new holes and countersunk them apropriately now it mounts up just fine!

All major mechanical reassembly is complete! Now just need to remount the Steppers, limit switches, spindle and cable chain.

-

10-14-2019, 01:49 AM #72

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

IT'S ALIVE!!

Finished all major mechanical assembly, just need to setup the limit switches, table and tune the machine!

https://youtu.be/iuPB33bhkkM

-

10-15-2019, 05:51 AM #73

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Did interest in this die? Had several people posting, and now that I am getting pictures up.... crickets.

-

10-15-2019, 04:55 PM #74

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

Re: CRP4896 Standard to Linear Rail Conversion

I'm still watching. I'm curious about the technique you used to position the linear rails. The current Avid kits use what they call a "rail alignment jig" to set the rails at each end and at the splice. Apparently, they use the jig at the splice because they use 2 pieces of linear rail for each side of the Y axis. There is a potential problem with the technique: Linear rails have no spec for straightness and may, in fact, not be perfectly straight along the length. Also, it doesn't take much to flex them by several thousands. Add to this the potential for the extrusions not being perfectly level along the length and chance of some degree of misalignment increases. How did you address all the variables?

Gary

-

10-15-2019, 06:35 PM #75

Registered

Registered

- Join Date

- Jan 2015

- Posts

- 194

Re: CRP4896 Standard to Linear Rail Conversion

I’m watching so please continue to share.

And I used their jig in a few places since I have a 10’ machine with no rail splices but my machine is not flat across its length. I should probably adjust at some point but to this point I haven’t. Then again, also not sure of the best way to flatten it as I don’t have a flat reference to work with.

-

10-16-2019, 12:31 AM #76

Member

Member

- Join Date

- Apr 2016

- Posts

- 841

Re: CRP4896 Standard to Linear Rail Conversion

David,

Here's a technique for measuring flatness that mactec54 wrote in one of my threads.

"A simple small roll of piano wire ( .020 Dia or similar can be smaller dia ) and feeler gauge set is all you need, you need to make a fixed block for one end of the piano wire, and the other mounting block so you can tension the wire, both blocks are fixed mounted by bolting or clamping, they must be rigidly mounted, this is simple and can be very accurate within .001 can be achieved

When making your adjustable side for tensioning the piano wire, think of a simple tuner like on a guitar can be just a bolt to wind up the wire"

This would allow you to establish a reference surface.

Maybe you should start a thread and provide detailed information (with pics) on your setup. I'd bet some folks here on the Zone would have some good suggestions.

Gary

-

10-16-2019, 12:51 AM #77

Registered

Registered

- Join Date

- Jan 2015

- Posts

- 194

Re: CRP4896 Standard to Linear Rail Conversion

Thanks Gary! That sounds simple and effective.

-

10-16-2019, 01:34 AM #78

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

GME i used the avidcnc block style, but a screw with jam nut in a threaded hole to set the depth. The linear rail is straight to within .002 over its length to the best of my ability to measure using a machinist straight edge and dial indicator.

-

10-19-2019, 06:54 AM #79

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

All the limit switches are connected, now the tuning can start.

-

10-29-2019, 03:27 AM #80

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: CRP4896 Standard to Linear Rail Conversion

Spent Friday and Saturday installing table and squaring machine up, it is as square as I can make it.

Bored holes in baltic birch subtable, and installed 64 1/4-20 threaded inserts for clamping in the front middle of table.

https://youtu.be/1487keBiCgw

Similar Threads

-

HF 8x14 linear rail conversion....and maybe more...

By CS900 in forum Mini LatheReplies: 99Last Post: 08-10-2022, 02:12 PM -

Standard linear motion conversion to linear rails.

By bobmagnuson in forum Avid CNCReplies: 11Last Post: 03-25-2022, 09:52 PM -

G0704 Linear Rail Conversion

By BTP in forum Benchtop MachinesReplies: 63Last Post: 07-14-2019, 01:59 AM -

Sieg X3/SX3 Linear rail conversion

By DvG4 in forum Benchtop MachinesReplies: 1Last Post: 01-16-2011, 02:17 AM -

Mixing Preloaded&Standard linear trucks on same rail -pros and cons ?

By isvflorin in forum Linear and Rotary MotionReplies: 2Last Post: 01-13-2009, 06:05 PM

Reply With Quote

Reply With Quote