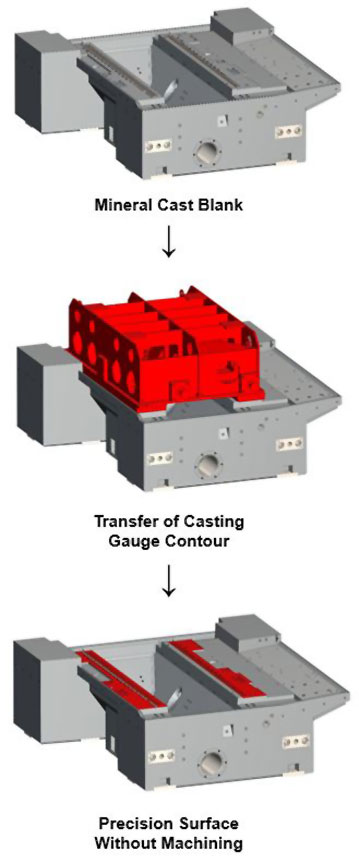

Not sure what this diagram is showing

Normally you make some surfaces (like a steel bar machined for a linear rail) that you precisely mount to the mold frame, and then they get cast in with anchoring devices. No post machining of any kind is involved.

Thread: Milli a new composite mill kit

Results 521 to 540 of 2105

-

01-02-2021, 05:50 PM #521

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

Re: Milli a new composite mill kit

-

01-02-2021, 06:25 PM #522

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Milli a new composite mill kit

Yes this is normal what a lot of the manufactures that do EG type casting do, the steel required is fabricated or cast, stress relived, blasted clean, machined and Ground where needed some may add some coatings on the steel before machining

So all the casting is doing is adding damp and weight to the steel or cast iron structureMactec54

-

01-02-2021, 06:40 PM #523

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

Re: Milli a new composite mill kit

I don't think you looked at the pictures close enough.

There's a precast EG base - no steel necessarily involved, with no precision surface for the rails and ball screw mounting. Then they seem to "recast" a new precision surface on top - probably with a fine AlO3 aggregate. I have seen people do this in the EG thread here.

This is actually similar what is done when reconditioning dovetail machines - recasting with moglice (similar to turcite B) using a form.

My only thought is as I said above, I think the general wisdom is to not directly mount rails and screws onto the EG. You also need to remember with an aluminium oxide surface, you have zero ability to correct anything without sending it to a diamond grinding facility.

-

01-02-2021, 07:47 PM #524

Registered

Registered

- Join Date

- May 2016

- Posts

- 316

-

01-02-2021, 10:15 PM #525

Member

Member

- Join Date

- Jul 2018

- Posts

- 6334

Re: Milli a new composite mill kit

Thanks Ard - Yes a guage or countermould can be used to create the reference surfaces post casting. The registers can be cast in directly as well. Once the concept is firmer manufacturing issues & costings will be brought into the design. Well done Ralph...

Studer cast their bases then recast the ways

https://www.youtube.com/watch?v=RwbY...ature=emb_logo

Peter

-

01-02-2021, 10:25 PM #526

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Milli a new composite mill kit

Don't have to I have been in some of these factory's that cast there machine bases / parts, any of the good one's are doing pre machined parts which are precisely placed into the molds

They insert the red part in there drawings, which is normally all machined Steel or Cast Iron, no finishing to do after casting, they are completely ready for assembly

The pictures are only a rendered drawing they are not going to show you all the detailsMactec54

-

01-02-2021, 10:49 PM #527

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

Re: Milli a new composite mill kit

That's not at all what those pictures show.

-

01-02-2021, 10:57 PM #528

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

Re: Milli a new composite mill kit

Those are hydrostatic ways. The "granite" is the linear way itself. So, very different usage than bolting the steel rails down onto.

Datron uses real solid granite for their bases, and bolt things to it, but i think EG is prone to movement and creep when you bolt the rails on directly.

Should look up to see if any commercial EG machines have the ways bolted directly to the surface, without a steel plate insert. The tech has progressed over the last few years, so maybe its ok now on a light machine like yours.

-

01-02-2021, 11:25 PM #529

Member

Member

- Join Date

- Nov 2020

- Posts

- 361

-

01-02-2021, 11:31 PM #530

Member

Member

- Join Date

- Jul 2018

- Posts

- 6334

Re: Milli a new composite mill kit

Hi Martec et al - If the EG is correctly post cured I'd expect no creep to occur. In a prior role I engineered composite parts for elevated work platforms. These fibreglass parts replaced steel parts for EWP's that where used on high tension power lines and formed part of the insulation for the workers. One of the concerns was losing tension on the bolts due to creep or relaxation of the laminate under long term bolt compression loads. So I set up a dummy part and kept track of the bolt tension over a period of a year. No loss of tension occurred. The epoxies the DIY EGers use with very low activity hardeners maybe a different matter. To be able to cast thick sections with no runaway exotherm low activity hardeners have to be used. To fully cure the epoxy post curing is required and DIY generally don't do this. So the epoxy will not achieve full hardness or cure at ambient conditions. I'm sure the processes used by commercial EG people would be able to produce parts where rails etc could be bolted to the part directly with no concern of relaxation. I say relaxation as creep is unlikely in this situation. There is a slight difference between creep and relaxation mechanics in plastics. Peter

-

01-02-2021, 11:40 PM #531

Member

Member

- Join Date

- Jul 2018

- Posts

- 6334

Re: Milli a new composite mill kit

Hi Ralph - Are the bolts at the back of the arm hard to do up? Are the cars snug in the gutter and this gutter is the prime alignment for the rails? I don't like the arrangement but it maybe a solution to make the arm stiffer...Peter

-

01-03-2021, 01:04 AM #532

Registered

Registered

- Join Date

- May 2016

- Posts

- 316

Re: Milli a new composite mill kit

Peter,

I didn't model it, but the outboard flange side of the right side head gutter has four grub screws to tighten the cars against the opposite (inboard) edge. The cars are a close fit, but not tight. Perhaps 0.005" sideways clearance.

The inboard side has been scraped slightly, presumably to get the head aligned with the Z-axis rails when the grub screws are snugged up. This is what I used for a reference surface while indicating the head for boring out the spindle hole.

The inboard car mounting screws are accessed through the column from the back. There are two holes which permit a long hex wrench or extension to line up with the car holes. You have to raise and lower the head to get to all four... see the two pipes I cast in place on the column? Those are so I can access the car bolt holes.

If you look closely at the first photo below, you can see at the left side a couple of holes in the head casting on the outboard edge/flange. Those are for the lower car, and there are two more for the upper.

All of the other car mounting points on the saddle have similar grub screws to force the trucks up against a reference surface. Second photo is of the saddle Y-axis, and you can see the (loosened) grub screw which bears against the left-front car.

-Ralph

-

01-03-2021, 01:26 AM #533

Member

Member

- Join Date

- Jul 2018

- Posts

- 6334

Re: Milli a new composite mill kit

Hi Ralph - Thks for extra photos. This design area is always a fiddle...I think in Millis case rear holes thru saddle and column would mean really really long extension for wrenches etc... so rear access is out at the mo... I was looking for some materials for the arm and came across some Plutonium but its the same stiffness as titanium

lots of depleted uranium around E=175GPa... Currently steel is 18kg Al is 6.3kg... CSA is 7kg... Tomorrow businesses start opening up so I can go get some CSA to play with... Peter

lots of depleted uranium around E=175GPa... Currently steel is 18kg Al is 6.3kg... CSA is 7kg... Tomorrow businesses start opening up so I can go get some CSA to play with... Peter

-

01-03-2021, 02:14 AM #534

Member

Member

- Join Date

- Jul 2018

- Posts

- 6334

Re: Milli a new composite mill kit

Hi All - New ER version details:

1) Shall be able to take ER16 standard and BT-30 optional power head. 750W and 1kw servo drive options.

2) X 450 Y 200 and Z 300mm

3) nose down ht from bed approx 75-100mm nose top ht from bed 400mm

4) prefer max part weight to be 50kgs currently base is 100kg and the column is 75kg

model stiffness X 19 Y 16 and Z 13 N/um this is achieved with the arm and saddle in steel. (Target actual stiffness >10N/um all axes ) Steel not ideal still thinking about the arm geometry and material. The crux geometry is not ideal for torsion or bending.

The column and base is CSA at E=40GPa Hopefully testing shows I can get higher then that. Will make the base deeper.

The struggle continues. Peter

-

01-03-2021, 03:54 AM #535

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Milli a new composite mill kit

Here is a better look at what some manufactures do there castings, it can be done in more that one way some Grind and lap the castings that just have inserts in for all the mounting points

Studer is one of the companies I have had a tour of there manufacturing, there surfaces that do not have pre machined inserts are Ground and lapped

China has many manufacturers doing Mineral Casting some also machining straight from solid Granite and add inserts so there are may ways it can be doneMactec54

-

01-03-2021, 03:57 AM #536

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

Re: Milli a new composite mill kit

I was talking about THAT picture as it was brought up as a method to do it.

-

01-03-2021, 04:00 AM #537

Member

Member

- Join Date

- Jul 2018

- Posts

- 6334

Re: Milli a new composite mill kit

Hi Guys - We are discussing the proverbial cat problem and there are many solutions. Lets move along to the next hurdle... Peter

-

01-03-2021, 04:02 AM #538

Member

Member

- Join Date

- Jul 2018

- Posts

- 6334

Re: Milli a new composite mill kit

Hi Guys - We are discussing the proverbial cat problem and there are many solutions. Lets move along to the next hurdle... Peter

https://www.bnd.com/living/liv-colum...20inside%20out.

-

01-03-2021, 04:02 AM #539

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

Re: Milli a new composite mill kit

You haven't even passed the first hurdle, which is what your machine is. Every post is entirely different.

-

01-03-2021, 11:35 AM #540

Member

Member

- Join Date

- Jul 2018

- Posts

- 6334

Re: Milli a new composite mill kit

Evening All - have used a sub plate for the column. This is currently steel but will be aluminium I hope. It can be used to square the rails then the column is bolted on top and set square. The big hole needs to be removed with a central ligament. The static stiffness is well balanced at X 15 Y 18 and Z 15 N/um. I have a hollow aluminium arm but will use the same subplate philosophy on the arm next time around. The front face is 25mm thick but you can see it flexes too much.

The subplate also allows MACHINING of features for the cars (will keep a few onlookers happy)

I prefer Al is it lighter and can be anodised. The machinist I use makes tonnes of aluminium parts and gets most of it anodised so he gets Al and finishing at good rates... I changed the base thickness from 150mm to 200mm and it made a big difference but now its quite heavy may have to be two pieces. Peter

Similar Threads

-

WillMill - HSM Benchtop Composite Mill

By Williamlii in forum CNC Wood Router Project LogReplies: 56Last Post: 05-31-2020, 07:03 AM -

Creating 3D model to mill molds for a composite RC glider

By Snowy in forum Hobby DiscussionReplies: 1Last Post: 07-11-2018, 04:14 AM -

Composite Mini Benchtop Mill / Router

By ficklecycler in forum Benchtop MachinesReplies: 10Last Post: 06-01-2018, 12:22 PM -

Looking for some composite routing

By Locster13 in forum DIY CNC Router Table MachinesReplies: 3Last Post: 11-02-2006, 05:20 PM

Reply With Quote

Reply With Quote