I have seen some discussion online regarding making PCB directly with CO2 laser by eliminating unwanted copper with laser and leaving copper traces.

Is this a possible scenario? I heard so many different opinions that I am truly confused and want to hear from experienced members here.

Besides CO2 laser (just ordered),

my lab does have a Xenon-Phosphorus-Neon gas laser that cuts thin copper like butter....I think this would work for making PCB directly, but I don't have experience with CO2 laser.

Any help appreciated.

Results 1 to 20 of 31

-

07-29-2007, 05:48 AM #1

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 7

Making PCB with laser (no chemical etch)

-

07-29-2007, 07:39 AM #2

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 100

I know this one will I've seen it done. the problem is it takes experance and a learning curve to get it right!

An idea that is not dangerous is unworthy of being called an idea at all, and Consistency is the last refuge of the unimaginative.

-

01-25-2008, 12:14 AM #3

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 63

I am going to paint some black paint on some FR4 to be used as acid resist, and then i'm going to etch away the un-needed paint.... Wanna see some pics of the results? You guys ever try this method?

-

01-26-2008, 09:44 PM #4

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 7

If you get a good result trying black paint, could you please share your result pics?

I have seen this method discussed in this forum somewhere.

-

01-26-2008, 09:46 PM #5

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 7

-

11-02-2008, 12:30 AM #6

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 25

I did last night, it works great. A lighter weight copper board will prevent undercut. The etch I did looks pretty impressive. I put Scotch tape across a board, two light coats of Duplicolor flat black allowed to dry in between, then etched. The black paint came off easy with acetone.

Ill post pix later.

Now, I am trying to figure out HOW to remove the black paint, been thinking laser but its starting to sound cost prohibitive.

I got my power supply yesterday, have a controller board on order, and the concept for the mill in my head.

Cheers-

Andrew

-

11-02-2008, 10:02 PM #7

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 25

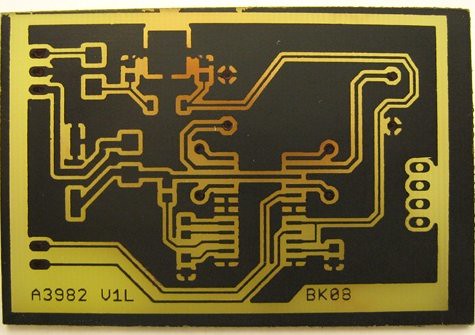

Here is the test results of using paint to resist etch. Worked out great! Now, to figure out if an inexpensive laser would work to burn away the black paint... or what other method would be used?

Here are the pictures as promised:

HTH-

Andrew

-

11-05-2008, 07:29 PM #8

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 63

Here is a picture of my results (after etching) and a video of the process.

I used rubbing alcohol to remove the paint that re-deposited back onto the surface of the copper. This actually seems to be quite a problem. If I do not use the proper speed and power settings (perhaps 20 speed and 60 power?), then I get bad results due to the paint I am not trying to ablate burning, or the paint that I am ablating sticking back to the the surface of the copper.

-

12-12-2008, 06:28 PM #9

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 139

-

12-18-2008, 09:03 AM #10

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 63

It is a Laserpro Explorer II. I do not own this one, it belongs to the University of California, Santa Cruz.

-

12-19-2008, 05:47 PM #11

I thought (by the title of the thread) that you were looking for a NON-etch laser process?

thanks

Michael T.

"If you don't stand for something, chances are, you'll fall for anything!"

-

12-21-2008, 06:37 AM #12

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 63

I'm not sure that you CAN do it by just etching off the copper. The fiberglass underneath would not take well to that at all.

-

12-21-2008, 06:16 PM #13

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 327

-

04-08-2011, 04:25 PM #14

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 422

Ok, I know this is an old thread, but this is what I am trying to do and was cutious what the results are. I have a 120 watt laser and need to make a PCB. I was wondering if anyone had success with the "no chemical" aspect of making the boards. I have never made my own board before so any help would be great.

Thanks!Necessity is the mother of all invention (unknown)

My club home page www.lhmac.org

-

04-08-2011, 07:01 PM #15

Member

Member

- Join Date

- Nov 2010

- Posts

- 787

Dont loose your time. No way to make it without chemistry.

-

04-09-2011, 05:23 AM #16

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 0

Could you use a CNC router, and cut down a fraction of a mm below the copper?

-

04-09-2011, 08:36 AM #17

Registered

Registered

- Join Date

- Nov 2009

- Posts

- 314

CNC Router on PCB board

Agreed bpoulin cnc router suggestion,here are some photos for special tools for PCB boards.if need I can check you some details of PCB tools.

Mike

-

04-09-2011, 10:07 AM #18

Member

Member

- Join Date

- Nov 2009

- Posts

- 707

For very simple one off pcb's I have found isolation routing to be quick and cost effective. Most of my prototype stuff is made this way.

For more complicated boards, spraying with car paint, laser etching, then chemical etching is quick and easy but better suited to surface mount (as there is no drill file, through-hole would be a pain to drill manually). Tweakie.CNC - Making stuff - Printed Circuit Boards.

Tweakie.CNC is only limited by our imagination.

-

05-27-2011, 05:13 PM #19

Registered

Registered

- Join Date

- May 2011

- Posts

- 0

Might be possible

I have been exploring this as well, first idea was to use a UV laser on a 2 axis CNC and then chemical etch, however directly etching with the laser seems even better, here is a video of the process in action.

Would love to hear comments from anyone experienced with laser etching, I would really like to build one of these.

-

05-27-2011, 05:35 PM #20

Member

Member

- Join Date

- Nov 2009

- Posts

- 707

Mike,

Direct etching copper with a laser is going to cost serious money.

Tweakie.CNC is only limited by our imagination.

Similar Threads

-

What chemical do you add to your laser chiller?

By grawley in forum Laser Engraving / Cutting Machine General TopicsReplies: 16Last Post: 06-03-2014, 08:12 AM -

Cannot laser etch anodised aluminium

By jimmykeeley in forum Commercial LaserReplies: 0Last Post: 12-01-2013, 08:08 PM -

HELP! Laser Etch Bare Aluminum then anodize

By gstar1988 in forum Engraving MachinesReplies: 3Last Post: 09-28-2011, 03:59 PM -

Laser Etch Bare Aluminum then anodize

By gstar1988 in forum Hobby DiscussionReplies: 1Last Post: 08-25-2011, 03:40 PM -

Laser Etch Job

By clembrant in forum Employment OpportunityReplies: 0Last Post: 04-08-2008, 07:17 PM

Reply With Quote

Reply With Quote