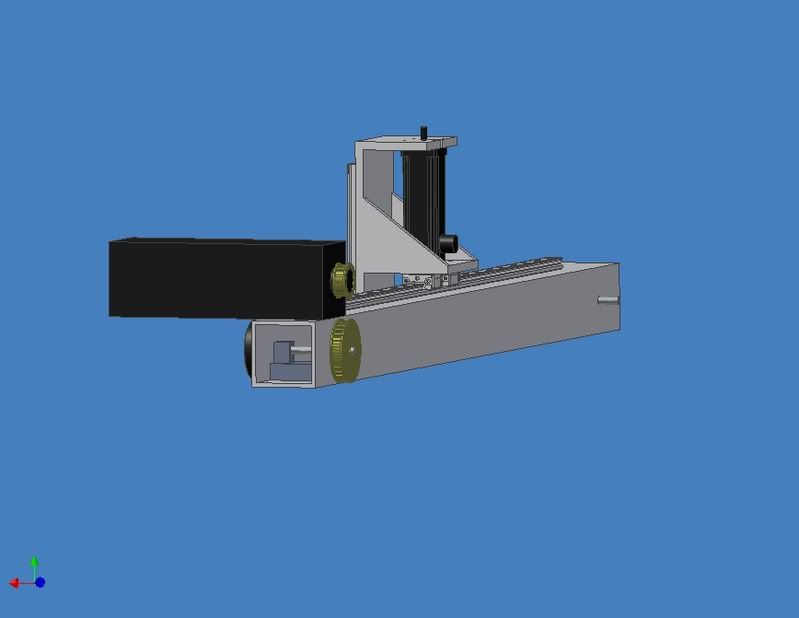

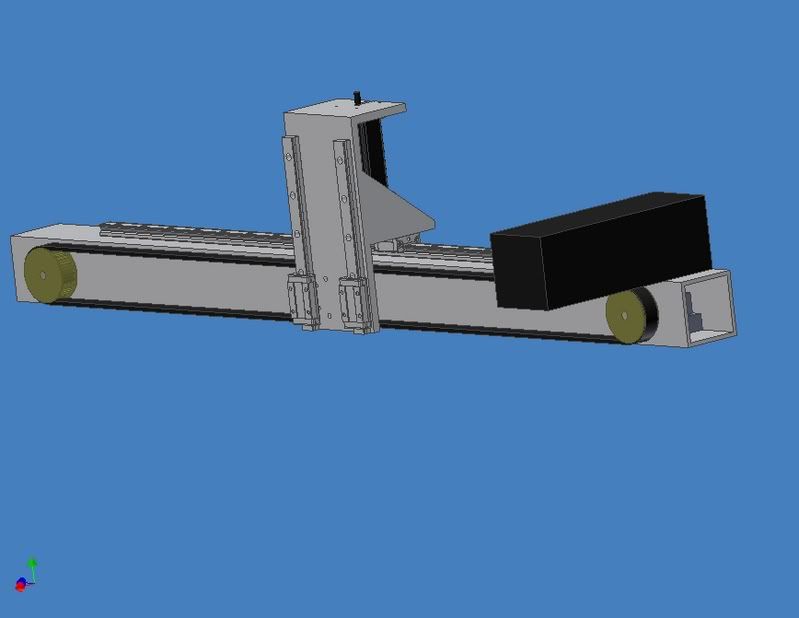

I am doing a 4X8 router table with some belts for power transmission. I have been looking at different ways to hold tension. One is just to pull one pully away from the other. I think this would work when the distance is not to great but what about when the distance is 8 feet? Should I use a roller under and over the pullies to hold tension? Here is my Y axis. I am thinking with this that pulling one away from the other will work here. The issue will be when I mount this on the rails and the whole assy moves 8 feet. What are some solutions for tension on a long belt?

Thread: Belt Tension Options??

Results 1 to 6 of 6

-

09-18-2007, 08:54 PM #1

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 95

Belt Tension Options??

-

09-19-2007, 02:57 PM #2

Registered

Registered

- Join Date

- Oct 2006

- Posts

- 735

I don't see any major issues with it other then the gear ratios. I'm not a huge fan of my ball screw drive on Y since it's slow (high limit to maybe 200ipm) .. If I really wanted to go faster I'd look into a belt.

But I'd be thinking of smaller pullies on the ends. Guessing you are tensioning them by pulling one of them away from the other? I'd rather try that then having an idle pulley how ever the having a little idler pullie on the slack side might be nice just to control any belt flap or vibration on that long section. Also figure on having some sort of screw setup to pull on your bearing blocks to put tension on the belt as you are pulling them apart.. Don't think you will get the tension on that belt that you will want to have with out some sort of tension knob type thing before tightening the blocks down.

You going with stepers or what here? (thinking about the ratio.) as you might also be looking at needing a planetary trans or something to gear it down. On my X I have it geared with a 10:1 planetary to 18t/24t belt to 1" round rack pinion. So in this case if you were to have 1" round belt pulley's on the main belt you would still need to gear it down more before the drive motor (least in my little world.) I would not mind gearing mine down even more then it is how ever I can get 600ipm to 800ipm on that axis as it is so it's about perfect the way I got mine..

HOpeufully some good suggestions.

b.

-

09-19-2007, 05:20 PM #3

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 95

I am using servo motors. The small one is around 300Watts and the large is 750. I am going to go with a belt system to the Z axis ball screw. The large motor is for the Y travel as you can see. I am going to gear it down as much as possible (5:1) with pullies off the motor to the belt system. the reason I have the large pullies on the belt system is that I am thinking more tooth engagement with the belt. Is there a down side to doin this? Why would I want smaller pullies?

You can see from the picture that I am missing a linear rail running inside the belt. This is the other reason that the pullies are big so that I can clear the rail.

-

09-19-2007, 06:31 PM #4

Registered

Registered

- Join Date

- Oct 2006

- Posts

- 735

Just was thinking smaller pullies on either side as the bigger they get the more you are increasing your gear ratio and the slower your servo will move per movement of the gantry. Servos like more rotation per move far as I know. Thus smaller pullies on either side would gear you down even more. Tooth engagement is something you will have to consider how ever I don't think they have to be 2" or bigger round pullies to have enought teeth in to do the job but that is just in my head.

-

09-19-2007, 07:13 PM #5

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 95

I see what you mean now. 1 turn equals more distance traveled because diameter is larger. Sometimes I do not think about everthing! I will keep them as small as possible, just enough to clear my rail and truck. Thanks.

-

09-19-2007, 08:06 PM #6

Registered

Registered

- Join Date

- Oct 2006

- Posts

- 735

Actually I'd have the loop either above or below the truck if I were you. Around the truck means dissassembly if you needed to put a new belt on. Unless you are using a split belt with a holder in the middle or something I guess..

if it's a solid loop best to make it able to be removed and replaced with the least amount of rebuilding or taking apart of other things... Also depending on how much force you are going to want to apply you are perhaps going to want to see a 10:1 reduction on the belt drive shaft if you used a small 1" pulley. But again I'm just juggleing eyeball numbers in my head and based on how I'm driving my Z...

b./

Similar Threads

-

Timing belt tension requirements vs backlash

By jensor in forum Mechanical Calculations/Engineering DesignReplies: 1Last Post: 05-20-2007, 08:04 PM -

Torch tension input for a PIC [ THC ]

By MaXx in forum CNC Machine Related ElectronicsReplies: 4Last Post: 05-14-2007, 01:23 AM -

Tension/compression tap holders

By Caprirs in forum MetalWork DiscussionReplies: 8Last Post: 04-05-2007, 01:59 PM -

Wire tension

By gguidi in forum CNC Wire Foam Cutter MachinesReplies: 1Last Post: 10-20-2006, 03:40 PM -

Belt Tension Adjuster Design

By mxtras in forum Mechanical Calculations/Engineering DesignReplies: 8Last Post: 05-16-2005, 04:33 PM

Reply With Quote

Reply With Quote