CNC Write is now ready to download. Get your free demo at http://cncwrite.com

CNC Write is a brand new engraving program that is designed to make fast work of common engraving operations. The interface is simple and easy to use. No hunting through cryptic menus for options. If you are familiar with writing your own G-Codes, it is easy to make custom font's and symbols to use in CNC Write. CNC Write was not intended to be used for fancy engraving on signs and plaques, However by designing your own fonts and building a font file, that type of work can be done with CNC Write.

There are two versions, Standard Mill mode and Integrex. The only difference is the Integrex version adds all the features you need for cylindrical interpolation on the Mazak Integrex. Integrexman at integrexmachinist.com can answer your questions about the Integrex modes.

I haven't decided on a price yet but I can say that the highest it will be is 300 for Mill version and 400 for Integrex. It will very likely be less than that though.

The only difference between the demo version and the registered version, is the demo version will randomly replace letters with an 'X'. Once you purchase a registration key, and register the program, that will no longer happen. Please note that the 'X' will often be a different width than the letter it is replacing, this may cause some overlap with that X and the next letter. This is not a problem with the registered version.

If demand is high, many new features will be added in the future. Give the program a try and let me know what you think and what else you would like it to do.

Chris W

Thread: New Engraving software CNC Write

Results 1 to 20 of 23

-

02-19-2008, 10:59 PM #1

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 16

New Engraving software CNC Write

-

02-22-2008, 12:16 AM #2

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 16

Some people were having trouble downloading the font files. Clicking on the link would open the file in the browser window. Now it should prompt you to download them instead.

Let me know if you have any trouble getting the program to work.

Chris W

-

02-25-2008, 06:52 PM #3

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 16

The price for CNC Write has been set. The Integrex version is $299.99 and the Mill version is $199.99. Payment can be made via paypal, there is a link on the registration page on the web site CNCWrite.com Registration page

Chris W

-

02-28-2008, 05:42 PM #4

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 16

If you are having trouble figuring out how to use CNC Write, be sure to read the notes below the screen shots on the web site here...

Screen Shots

Also note that you can click on each tab and on the different sections above the tabs to get notes on how to use each group of settings.

Here is a video of CNC Write engraving on mill with a rotary axis.

Video

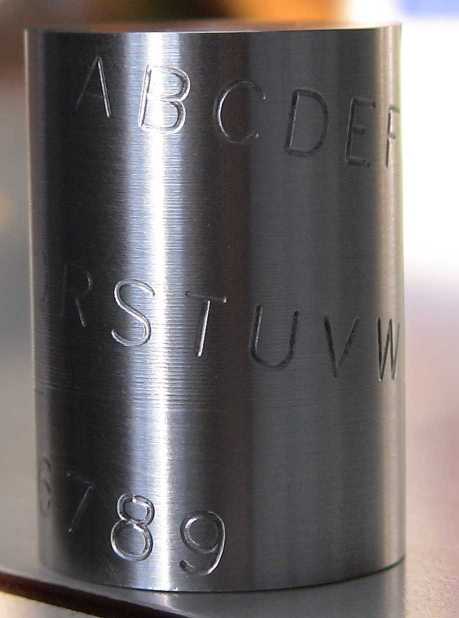

Here are some examples of what you can do with it as well.

Chris W

-

03-01-2008, 01:46 AM #5

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 16

I have some videos of CNC Write in action on an Integrex and photos of the finished part.

I have also fixed A minor bug in the way the program calculated the start point of engraving when using a rotory axis, and a small bug with the Integrex using G16, when engraving around the part more than one full revolution. If you have already downloaded the program you may want to download it again if you use either of these features.

Integrex Using G12.1 Video

Integrex Using G16 Video

Chris W

-

03-06-2008, 08:16 PM #6

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 16

I have a photo and video of CNC Write on a mill using XAZ for engraving using a rotary axis to engrave on a cylinder.

XAZ Engrave Video 3.6 MB

Chris W

-

02-02-2009, 02:31 AM #7

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 2

will this work for a Milltronics Controll?

-

02-02-2009, 02:58 AM #8

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 16

The program outputs standard G codes. G00 and G01 is all your machine needs to support for standard engraving. The best thing to do is just download the program and try it out. The only difference between the download and the registered version is the free download will randomly replace letters with an 'X'. If you have problems getting it to do what you need let me know and I can help.

Chris W

-

01-24-2011, 06:15 PM #9

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 58

just found

I just found this software looking for a way to do rotory engrave on a Mazak vtc 200 c. I downloaded the trial but can not get good results. I am gettin A moves over 360 degrees. any help

-

01-24-2011, 07:19 PM #10

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 16

Can you post a screen shot of the settings you are using?

Chris W

CNC Write Developer

-

01-24-2011, 07:42 PM #11

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 58

Pic

Here is the pic. I can do this very simple on my haas but machine time I have to use my Mazak. If I can get it working we can purchase the full version

-

01-24-2011, 07:43 PM #12

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 58

one more note

I didnt have the inverse time feed checked but tried both ways

-

01-24-2011, 08:03 PM #13

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 16

The first problem I see is the Plunge Axis settings. The "Down" and "Up" values need to be relative to the the radius of the part you are engraving on. If the radius of the part is say .5 and you want to engrave .005 deep then "Down" would be .5 - .005 or .495. If You want a clearance over the part of .02 for rapid moves, then the "Up" should be .5 + .02 or .520.

The software needs to know the radius it is engraving at and the "Up" and "Down" Plunge axis settings is how you tell it that. Hope that helps. There may be other issues but that is the one that I saw at first glance.

Chris W

-

01-24-2011, 08:07 PM #14

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 58

Simple

ooohhhh. I new that it needed that but did not know where to tell it. Thanks a million.

-

01-24-2011, 08:24 PM #15

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 58

?????

I changed the Z depths. Still getting som crazy feeds . Do the Axis look correct for standard rotory setup? thanks

-

01-24-2011, 08:25 PM #16

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 58

PIC

Pic didnt load last post

-

01-24-2011, 09:52 PM #17

Registered

Registered

- Join Date

- Aug 2006

- Posts

- 62

You must have Axis1 set to X and Axis2 set to A and Plunge axis set to Z. This is if you have the A axis in line with X on the right end of the table. Your work offset for Y0.0 and Z0.0 must be in the center of the cylinder you are cutting on. You must use Inverse time feedrate. The code should be something like the sample below. Start with something simple like ABC.

M1

G40 G90

T01T00M6

G54 G40 G90

S10000 M3

G93(must have inverse time option)

G00 Y0.0 M8

(First Z move)

(Engave)

.

.

G91 G28 Z0.0 M5 M9

M99

-

01-24-2011, 10:51 PM #18

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 58

THANKS

I can actually use the rotory on either side. I have one left and one right. I am going to use the right rotory. It is a disgrace to the Mazak but I have a HAAS 5c indexer mounted to a plate on the left side rotory to mill 10 slots on 15 deg for a product line. works good for a homemade 5th axis. I am going to try the engrave more

-

01-25-2011, 02:46 AM #19

Registered

Registered

- Join Date

- Aug 2006

- Posts

- 62

Let me know if it works.

-

01-26-2011, 05:35 PM #20

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 58

love it

I got to try the demo today and love it. great litte program will be purchaseing. are the owners of it on here

Similar Threads

-

Want to write a Complete Control Software: In C# Do I have to know C and C++???

By jeffserv in forum Dynomotion/Kflop/KanalogReplies: 11Last Post: 04-23-2014, 11:10 PM -

Engraving software

By TheMadEtcher in forum Engraving MachinesReplies: 0Last Post: 08-30-2010, 01:12 AM -

Engraving software

By phatjap in forum Engraving MachinesReplies: 0Last Post: 04-25-2010, 08:26 AM -

CNC Write Engraving software update

By cdw3423 in forum News AnnouncementsReplies: 0Last Post: 03-31-2008, 06:05 PM -

Engraving Software

By The Wizard in forum Uncategorised CAM DiscussionReplies: 31Last Post: 03-29-2005, 12:38 PM

Reply With Quote

Reply With Quote