I built this CNC Oxy/Acetylene torch table to do small runs of brackets.

It has a 30"x30" capacity and uses an un-modified hand torch (Victor Advantage II 250)

This shows the 24v solenoid and air cylinder that pushes the button. I use pin 8 and coolant A on/off to trigger the button in TurboCNC.

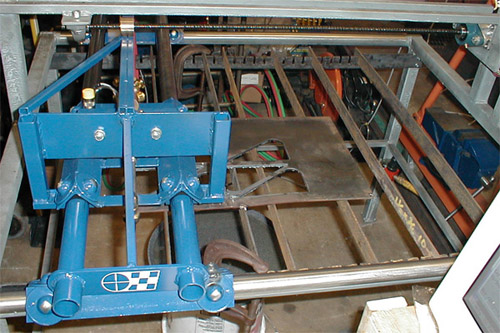

This shows the torch cutting parts for itself. This is the "Comb" that holds the work supporting "bed". I posted more info here: page 5 of Sanghera's post

It was (relatively) cheap ($1200, including torch & computer) and fun to build. I am using 187oz 23's, Xylotex drive, TurboCNC, 30v and get 106ipm rapids. It cuts 3/16" @ 49.5ipm. Just another way to skin a cat. Enjoy, MIKE

Thread: Homemade CNC Torch

Results 1 to 16 of 16

-

11-13-2004, 05:59 PM #1

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

Homemade CNC Torch

-

11-13-2004, 07:21 PM #2

Gold Member

Gold Member

- Join Date

- Aug 2004

- Posts

- 48

Good looking setup. Was the use of the bearings for the slides because you had them or for ease of construction?

-

11-13-2004, 09:11 PM #3

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

Cost, performance, but probably not ease. A cam follower can be $17. I looked at various machines using cam followers or bearings and decided there had to be a better, cheaper, way. Ball transfers seemed to be it. I didn't have to fab axles and brackets (skate or other bearings), and they were 1/3 the cost of mounted cam followers. It was a little tedious to bore the holes, that the balls pass through, in the angle. If you want them all to hit together, precision was paramount. I was able to bore the 16 holes in the angle, and they do all hit. Actually, precision machining and welding was the only "hard" part about building it. The table and gantry had to square and level, The balls all had to be mounted exactly the same. An adjustable, bolted, solution would have saved time but, added expense. I have more time than money. The ratio of set-up to welding time was probably 10:1. Proof is in the pudding, and it works really well, MIKE

-

11-13-2004, 10:30 PM #4

Do you have any close-up pictures of items that you have cut? I'm curious about how the cut edges turn out.

-

11-13-2004, 11:29 PM #5

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

Here are a few of the letter M (3" high). This isn't what I do with it, but I had it laying here.

This is an edge. Little fuzzy, but you get the idea. Main thing is that I am using a sander (with dust collection) instead of an angle grinder to finish them up. This hasn't been hit yet. I did rub it on the floor to get a few slag pimples off of the bottom.

Here is the letter M

These pics end up being about 70% larger than life on my monitor (800x600) You can see the kerf in the tips of the inside of the M. It is about .050" with a 00 tip. I have a 000, but haven't tried it. Should be about .030-.040". Since these were cut I have increased my feed rate from 30.5 to 49.5ipm. I had stopped at 30ipm previously because the torch's manual said that was the high end. I have done some testing since then, and can run 49.5 without blow outs. I also bumped up my accel and, am running off of C instead of A now. This helped a ton at minimizing pauses. This makes outside corners alot sharper. It will do holes, as long as they are big enough for some lead-in. I'm still learning. I am making chassis and suspension brackets for a tube frame trail buggy. They are bigger and less complex. It works very well for it's intended purpose. (Something cleaner/better than hand-torching) MIKE

-

11-13-2004, 11:49 PM #6

Very nice work, Mike.

-

11-14-2004, 12:29 AM #7

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

Thanks ! Especially when you consider that I had never even seen a CNC machine before building it. I started reading up, on the web, in January. I bought my first parts in March. I've had it running since October. It worked fine on the first cut. And I didn't follow the norms as far as concept or common practice. It could have been a huge (expensive) flop. My feet were a foot off of the floor when it first ran. I didn't turn a stepper untill 5 minutes before I started using it. I have never seen tube, ball transfers or air-operated button, used before. Another oddity is running the screws over the top. I had seen it done, but not on a metal torch machine.

http://groups.yahoo.com/group/Xylotex/message/2493

http://groups.yahoo.com/group/turbocnc/message/10451

http://groups.yahoo.com/group/DIY-CNC/message/6821

http://groups.yahoo.com/group/DIY-CNC/message/7387

http://www.pirate4x4.com/forum/showthread.php?t=293058

These are a few of the other threads I started (if anybody is really that interested). I am working on an unconventional desktop router project now. I may even have an eye twords re-sale on it. The labor invested in the torch precludes my building them for others. But, I am working on a more feasable small router design that I may be able to market. BTW, I looked at all of your project's pages as well. My hat is also off to you. MIKE

-

11-14-2004, 01:09 AM #8

Thanks for the kind words about my project. I hope it works when I finally get er done.

I've been trying to understand how the bearings on your machine work, but I've never seen anything like them or can't make them out. Can you tell me a little about them?

-

11-14-2004, 01:47 AM #9

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

They are ball transfer bearings. A 3/4" steel ball in a cup with 80 little balls. They are used various ways. Sometimes as feet on equipment and furniture, mostly mounted ball-up in conveyors. Here are some of McMaster's pics of them:

It was the last one that caught my eye. I had sold pipe storage rack that used that system at an earlier job. This is where the impetus came from.

The type I used

Loaded, they have zero play and each supports something like 80#. There are little oil holes in them, and I blow air through these, followed up by some light oil. The tubes were polished with oil and sandpaper. Those are the straightest sections selected from about 80' of tube. Luckily I have a ton of it around from the tube frame project. The end plates for the gantry were made on the mill, with careful attention to the centerline distance. The notched tubes for the table were welded together, before being birdmouthed in the mill, to insure equal length. I used a 1 1/2" roughing endmill to notch the tubes. It rolls along pretty nicely. MIKE

-

12-27-2004, 11:55 PM #10

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

Thats groups.yahoo , the link busting machine keeps making it hard to link to the "other guys" Originally Posted by accuratemike

Originally Posted by accuratemike

-

03-14-2007, 01:52 AM #11

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 1

accuratemike your table cool is there anyway i could get plans to build one for myself pls thankyou gkpwelder@yahoo

-

03-14-2007, 02:43 AM #12

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

Thanks! There was no plan. I actually started with a pile of parts and built the table around the torch and lead screws. Everything kind of dictated where everything else had to go. You can glean almost all of the information from the groups and posts listed. It has been a few years now, I have probably forgotten as much as I remember. It is still working (well). I did put some pictures here: http://www.accuratepower.com/Torch and something I made with it here: http://www.accuratepower.com/Rest . Good luck, I'd just look at the pictures and improvise. Enjoy, MIKE

-

06-19-2007, 10:15 AM #13

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 44

thats a wierd way to go but if it worked for you....

guess you jus need to think different

-

06-19-2007, 01:28 PM #14

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

Shashank, thanks (I think). Still works for me after 3 years. MIKE

-

01-03-2009, 11:18 PM #15

-

01-03-2009, 11:56 PM #16

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 71

Oakley,

Thanks! I just used it to burn out a cool motor-mount, (for a kid-vehicle I'm building), yesterday. Still works great. Now that I have it, I design more cool cut-plate stuff into everything I build. Don't know what I'd do without it. A few things are on my website ( http://www.accuratepower.com ). The kid-vehicle will someday be at http://www.trailcrawler.com . Thanks again, MIKE

Similar Threads

-

Using your CNC Mill as a CNC Lathe

By lstool in forum Knee Vertical MillsReplies: 11Last Post: 06-12-2017, 02:29 PM -

Using ProDESKTOP on homemade CNC router?

By jonbrown34 in forum Uncategorised CAM DiscussionReplies: 8Last Post: 06-08-2005, 12:18 PM -

Newbie to CNC world

By HighOctane in forum DIY CNC Router Table MachinesReplies: 6Last Post: 01-25-2005, 08:58 PM -

The start of a big CNC project...

By UKRobotics in forum Uncategorised MetalWorking MachinesReplies: 10Last Post: 09-30-2004, 11:34 PM -

Anyone know who made this website and homemade cnc?

By ljoe1969 in forum DIY CNC Router Table MachinesReplies: 2Last Post: 08-27-2004, 06:34 AM

Reply With Quote

Reply With Quote