Hello

I have begun the adventure of converting a new lathe and mill to CNC. This thread is where the discussion began. We will convert the lathe first, using the mill to help the process along. After the lathe is done we'll convert the mill.

The main goal of this thread will be to collaborate on creative ideas involving the conversion of the Grizzly 10x22 lathe, and the X3 mill.

We manufacture tactical training products as shown in the photo below:

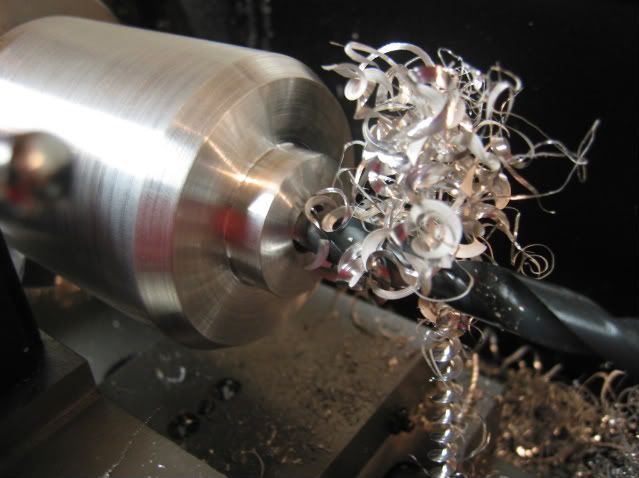

We have been using 7x14 lathes in our process, and have definitely outgrown them at this point. Here is one of our 7x14's taking care of a drilling operation:

Items that have been ordered so far:

1 G0602 10x22 lathe

1 G0463 mill (this is the Grizzly version of the X3)

1 G540 stepper motor controller

I was on the Keling CNC website, (which is a great resource for parts), but I couldn't find the KL23H284-35-4B 387 oz-in steppers on their order page? I left a message with them, but I was curious if anyone on the forum had any knowledge of why they aren't available?

I will be ordering my control computer from this site. We will be running Mach3, and I know that we need parallel ports, but is there anything else to look for in a control computer?

With the learning that will come from this work, I hope to offer much to the forum in the form of this thread and any questions that I can answer. In the mean time I'm sure that I will have many questions, but I'll do my best to search before I post.

We are in the process of ordering all of the necessary components for the conversion as well as modifying our shop to receive the new machines. Any tips on bench construction/modification would be great for a CNC conversion.

What is the best way to purchase Mach3?

We will be going with ball screws, and I will turn them down on the new 10x22, (great ball screw turning videos, scroll down). First I need some good quality tooling for the lathe with good indexable inserts. We will be ordering this quick change tool post. I have to admit that I am a bit unsure as to what tooling to purchase for the lathe. Any help with this would be great! The initial mill tooling will be this set from Little Machine Shop.

When looking into helical connectors to go between the stepper output shaft and the drive screw, do you choose connectors that will accept the OD of the stepper shaft and then turn down your screws to match? This makes sense to me but I want to be sure.

Is it fair to assume that, with attention to detail one can create a CNC machine from these machines that will work well and be reliable over a period of time?

Thank you all for your help now and in the future. More to come soon.

Results 1 to 20 of 144

-

02-15-2009, 08:52 PM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 101

Grizzly 10x22 lathe, and X3 CNC conversion build log

-

02-15-2009, 10:15 PM #2

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Looks like a lot of work in store to get two machines converted. Will you be using a kit for the mill to speed things up, or just going to do both from scratch?

RE lathe tooling, I like CCMT tooling with 1/2" shanks. Thicker shanks mean a bit more rigidity. I think Grizzly offers this tooling under the Glanze name. Micro 100 also has nice lathe tooling in the CCMT size.

Cheers,

BW

-

02-15-2009, 10:17 PM #3

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 402

Welcome aboard to the X3 conversion crew....

I too am going with the G540 and the KL23H284-35-4B 387 oz-in motors on all three axis. I ordered the motors from Keling this past week and he responded that he had them in stock and would ship right off. At least one other guy on the zone ordered these motors from him last week as well.

Have you decided whose plan your going with? Or are you going to make up your own?

Good luck with your conversion. Keep us posted as you go.

Matt

-

02-15-2009, 10:35 PM #4

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 212

Check here....2nd motor down from the top:

http://www.kelinginc.net/NEMA23Motor.html

-

02-15-2009, 10:55 PM #5

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 445

-

02-15-2009, 11:22 PM #6

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

They are available.

Mach3 needs at least 1 gHz speed--The more the better. Don't buy a computer with Vista OS--It can be flakey with Mach3--Get XP.I will be ordering my control computer from this site. We will be running Mach3, and I know that we need parallel ports, but is there anything else to look for in a control computer?

Keling offers a discount when you buy it with motors.What is the best way to purchase Mach3?

Yes.When looking into helical connectors to go between the stepper output shaft and the drive screw, do you choose connectors that will accept the OD of the stepper shaft and then turn down your screws to match? This makes sense to me but I want to be sure.

Yes. Just keep everything lubed each day. You may want to install hour meters and do maintenance at certain hourly intervals.Is it fair to assume that, with attention to detail one can create a CNC machine from these machines that will work well and be reliable over a period of time?

You might also REALLY want to look at the CR'S BEST BUY in this category: Novakon CNC ready NM-135 for $3600. While similar, It's a much more rugged machine than X3, with N34 motors, 3/4" ball screws, one touch oiling system Etc.

http://novakon.net/3.html

It will cost you that much to CNC the X3. With the Novakon, all you have to do is plug the motor cables into your controller and computer and start making chips.

AND, you could LEASE it. Which may be a good idea in these times of credit crunch.

CR.

-

02-15-2009, 11:26 PM #7

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Here's a good CNC conversion thread to help CNC your new G602:

http://www.cnczone.com/forums/showthread.php?t=59435

CR.

-

02-16-2009, 01:05 AM #8

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 402

Dude, your macine is in a class all by it's self!my homebuilt which is prolly somewhere between the X2 and X3.

Don't compare that beauty to any China builds.

-

02-16-2009, 01:23 AM #9

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Here's some video of a Novakon sister mill in action:

http://www.youtube.com/watch?v=OjAS2t9fXxs

http://www.youtube.com/watch?v=-RaEThG0I0A&NR=1

CR.

-

02-16-2009, 03:24 AM #10

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 445

-

02-17-2009, 05:49 AM #11

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 101

Update:

We have looked into the Novakon NM-135 mill and compared it to a few other X3 style turn key mills. After a bit of research I contacted Novakon and spoke with John, the owner, and Kai, their sails rep to hash out the details of a perspective order. They were very helpful and answered all of our questions. Due to our experiences dealing with them personally, and of course the mill its self, we have decided to place an order with them and cancel our Grizzly X3 mill order. The package that we will order tomorrow is as follows:

1 NM-135 CNC mill

1 CD 100 controller, (4 axes G203 controller)

4th axes rotary table, (sweet!!)

Coolant system

Machine stand

Bob CAM

Mach 3

1 year warranty

Shipping ($700 )

)

The guys were great to deal with, and we look forward to doing business with them in the future.

For the new mill, we will also order the Tormach quick change tooling system. Is the $725 kit worth it?

We are pushing forward with the 10x22 lathe project, and believe it or not, I can't decide which tool I'm more excited about.

These two machines are going to be a invaluable addition to our shop.

Speaking of the shop, we have somewhat retrofitted our working area and only have access to a limited amount of circuits/power, with no option of adding more.

This request may seem a bit off the wall, but how difficult would it be to build a battery bank with 12V deep cycle batteries and run them through an inverter to compensate for some of our power needs during heavy periods power usage? The battery bank would then be charged at night after closing time. Any thoughts on this would be great!

Will the NM-135 (KX3) fit on a 24" deep work bench?

Can one control computer run two machines at once? I'm thinking not.

-

02-17-2009, 06:12 AM #12

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 12

More, more...

-

02-17-2009, 06:12 AM #13

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

-

02-20-2009, 03:21 AM #14

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 101

Update:

I received my G540 today and made a new little friend. Thanks to everyone at Gecko.

The controller is beautiful, but I was also very pleased with the packaging.

The Novakon NM-135 CNC mill has been ordered with their CD-100 controller (4-G203Vs), Coolant system, and 4 inch CNC rotary table for $7,096 shipped to Washington.

The guys at Novakon are great! Thanks guys.

The Lathe is ordered (Grizzly G0602) as are the 387 oz-in steppers, power supply, and the Estop.

Much more needs to be purchased. What is a good CNC vise for the mill?

-

02-20-2009, 04:10 AM #15

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Looking good!

You CAN run two machines from the same computer--Just not simultaneously.

The mill and the lathe will use diferent xml files in mach. You load the one for the proper machine and load the Gcode file for that part.

The Db-25 cable from the computer is connected to an "A-B" switch. This switch has 2 more DB-25 connectors--One is A and the other is B. You connect A to either the mill or lathe and B to the other. A knob on the switch is turned to select the machine to be used.

http://sewelldirect.com/parallel-db-...l-switch-2.asp

This can easily be done, but is not as efficient as having two totally independant CNC units.

You will also need 2 pair motor cable wire:

http://cgi.ebay.com/Stepper-Motor-Wi...742.m153.l1262

You have never used a mill in your production process. You WILL need a production vise, and they are quite expensive. I recommend that you buy a good "starter vise" and work with it awhile to learn just exactly what you will need.

This $47 dollar vise is ok to learn with:

http://littlemachineshop.com/product...1145&category=

Or you could get this vise and milling video combo for $137.

http://littlemachineshop.com/product...3487&category=

It is MY feeling, that you will be using the 4th axis and chuck to hold most of your cylindrical parts. If you don't have a chuck coming WITH the RT, then you will need one. If you intend to use square stock, or want to exert less pressure on your aluminum cylinders, then you will need that chuck to be a 4 jaw. You probably will want a Scrolling 4 jaw chuck. That is self-centering and is easier to mount/unmount parts into.

CR.

-

02-20-2009, 04:39 AM #16

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 101

We are going to use one computer for each machine because we are going to run them both at the same time.

Is there an issue with having the net connected to a control computer? It would be nice to have access to the Internet on the computers when they are not being used for CNC.

Could someone advise if this computer will work well?

Kai at Novakon told me today that they have had a couple of issues of customers computers parallel ports not being compatible with their BOBs. Has anyone ever heard of this?

-

02-20-2009, 04:55 AM #17

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Those computers should be fine. I do not recommend having internet connection though. You want your production equipment isolated from the world of virus attacks and running only Mach3. Virus protection tends to interfere with Mach3 running parts.

You may need a temporary internet connection to download your Mach3 license, but after that, internet software should be removed.

What Kai is probably referering to is that Many computers come with 3V parallel ports instead of the required 5V. This can cause a BOB expecting 5V to have problems.

You may be able to contact Dell with the model number and find out what voltage your prospective computer is powering the parallel port with. Most of the older computers ARE 5V PP though.

CR.

-

02-20-2009, 05:02 AM #18

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

I have edited that previous computer post with vise and RT info. Did you read it?

CR.

-

02-20-2009, 05:27 AM #19

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 101

Yeah, I just read the edit, CR. What does a production vise for a small mill look like/go for?

No chuck is pictured in the RT photo on the Novakon website so I'll check on that. Do they usually come with come with them?

We use scroll chucks in our lathes now.

-

02-20-2009, 05:35 AM #20

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

LOL! How many stars are in the sky?

Depends on what you need, how you need to hold with it, and how fast you want to change parts.

http://kurtworkholding.com/

CR.

Similar Threads

-

Grizzly 10 x 54 mill CNC conversion

By robhrzic in forum Bridgeport / Hardinge MillsReplies: 79Last Post: 05-20-2023, 10:37 PM -

Grizzly G0602 10" x 22" Lathe Conversion

By derekbackus in forum Vertical Mill, Lathe Project LogReplies: 145Last Post: 01-29-2019, 09:29 PM -

Just got my Grizzly X3. CNC conversion to come...

By stag53 in forum Benchtop MachinesReplies: 36Last Post: 12-21-2009, 07:30 AM -

Grizzly 10x22 or Lathemaster 8x14

By C.BRAXMAIER in forum Mini LatheReplies: 2Last Post: 09-19-2008, 03:04 PM -

Any opinions on the Grizzly g4016 lathe or other Grizzly lathes?

By DublD in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 11-26-2006, 07:23 PM

Reply With Quote

Reply With Quote

But your compliment is appreciated.

But your compliment is appreciated.