I am looking to fabricate new water bed for my cnc cutting machine,I want to know more detail about the design of the water bed i.e the process of increasing/decreasing the water level.

anybody can help me on this?

Thread: CNC Cutting Machine Water Bed

Results 1 to 18 of 18

-

04-15-2009, 02:59 PM #1

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 5

CNC Cutting Machine Water Bed

CNC Cutting Machine Water Bed

-

04-15-2009, 03:17 PM #2

Most of the water tables have a tank built into the bottom....when air pressure (only 2 to 3 psi needed) is added to this tank of water....it displaces the water and forces the water level to rise in the main part of the cutting table. A simple hand or electrically operated valve then can release the air from this tank....and the water freely flows back in...lowering the water level in the main table. Very simple design.

For most plasma cutting needs....if the water is at the bottom level of the plate...it will adequately handle most of the smoke and fumes. If your plasma torch is designed for underwater cutting (not all are) then you can raise the water above the plated for submersed cutting. Submersed cutting will virtually eliminate fumes, will control cambering stress on long, thin parts, and also cuts down the noise and ultraviolet emmisions from the process. Unfortunately...when water contacts the cut...the edge lag lines become more noticeable and there is a higher chance of dross (resolidified metal) formation.

On some materials...stainless as an example...using nitrogen as the plasma gas and having the plate submerged....will produce a very clean, shiny edge free of the brown oxides that form with most plasma processes.

Jim colt

Jim Colt

-

04-15-2009, 03:25 PM #3

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 5

Water Bed Drawing

Water Bed Drawing

tq Jim

just small clarification,once I fill in the underneath tank with compressed air is't need to lock between the two tanks?I mean the top(table) and below(compressed air).

-

04-15-2009, 03:35 PM #4

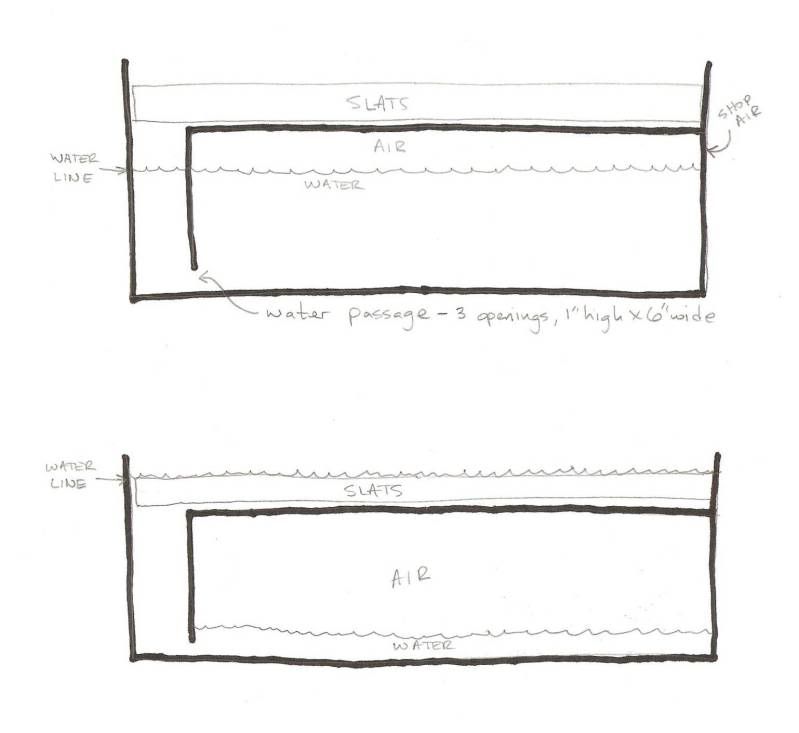

Think of an inverted box in the bottom of a water table....this box is full of water, and there is water in the water table as well. The bottom of the box has a slot that is open to the main water table. Now put an air hose in the inverted box...and turn on the pressure....the water will rise to the top of the box, and start to fill the box, forcing the water out. It takes roughly .5 psi to raise water 1 foot.....so if your water table is 2 feet deep....you don't need much pressure! As soon as you release the air from this box to atmosphere....the water will flow back in, lowering the water in the table. I can probably find a sketch somewhere!

A lot of people have forgotton....but the water table for use with a plasma torch was patented by Hypertherm in 1970...the patent has long since expired....but it is not new technology!

Jim Colt

-

04-15-2009, 04:04 PM #5

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 5

-

04-15-2009, 04:21 PM #6

As long as you maintain the air pressure on the box (known as a bladder)...the water level will stay up.

Jim

-

04-15-2009, 04:26 PM #7

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 5

jim,

is't possible to provide me simple sketch of the system?

-

04-15-2009, 04:32 PM #8

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 108

Water table with downdraft . . .

Water table with downdraft . . .

Is it safe to assume if you have a water table, you can not run a down draft system . . .

Why would you need to change water level, the top of the material support grate does not move . . .

Top of grate is always bottom of material to be cut . . .?

For a 4X4 plasma table in a garage, which would you say would be more practical, water or down draft?

How do you feel about wheels on a 4X4 plasma table?, with water or down draft?

Thanks,

Steve

-

04-15-2009, 05:29 PM #9

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 92

Jim, I'd sure like to get a peek at your water bed sketch.

I believe running a down draft and water bed would be very complex. To use the DD the WB would have to be lower to the floor? or removed? And since the slats are usually built into the WB they would have to be transferred to the frame to use with DD.

As I see it the downs sides to DD are ducting and a fan must be plumbed and in the winter it will suck the heat out of your shop.

One of the nice things about having the ability to easily lower the level in a WB is to retrieve parts or for cleaning. Plus IMHO I believe a WB gives the best vapor control.

-

04-15-2009, 10:44 PM #10

It actually can be beneficial to have a combination water table and downdraft table. If the water is 12 to 16 inches below the torch...it tends to trap many of the larger particles....as many as 60%. Above the water you can have a downdraft system (or side draft) that will pull the remaining particles out. This method....while more difficult to design and build,is easier on your filtration system if you are using one.

A good downdraft table that is zoned (only pulls in a relatively small area around the torch) is very effective as well...requiring lower flow rates as compared to a whole table downdraft. Downdraft provides the best cut quality....with no water contacting the cut face.

A water table can be close to 100% effective in controlling fumes if the plate is submerged.....works pretty well with the water at the bottom of the plate....and gets less effective as the water is lowered.

I will try to find a sketch of the raise lower mechanism...if not I may just hand draw one and scan it.

Jim

-

04-16-2009, 06:07 AM #11

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 83

-

04-16-2009, 06:09 AM #12

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 83

Does anyone know how shallow you can go with the water bed and still be as effective as possible?

-

04-16-2009, 11:45 AM #13

Hypertherm Powermax torches are not designed for underwater cutting...that being said, there are a few users using them for underwater applications. They will work...Hypertherm does not test these systems for underwater applications ...so cannot make recommendations for this use. Most underwater applications use our industrial plasma systems that are designed to be submerged.

As far as the dpth of the water...1 inch depth will work to help capture fumes....but it will quickly fill with slag and or evaporate. For low duty cycle applications there should be 4 to 6 inches of water. High duty cycle industrial water tables will typically have 16" to 24" of water in the the water table.

Jim

-

04-16-2009, 03:47 PM #14

Registered

Registered

- Join Date

- May 2003

- Posts

- 323

water tables

tof1,

I once installed one of our machines in Portland, OR area for a fellow doing very thin SS. His water table was about 2" deep; he had the water level just barely above the top of the workpiece, and the air exiting the torch blew away the thin layer of water, with excellent, non-warping cuts. He made weather vanes!!

Regards,

Jack C.

-

04-18-2009, 04:45 PM #15

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 92

A buddy of mine made a water bed for his ez-router table. I got him to make this sketch for us.

-

04-20-2009, 05:02 AM #16

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 5

tq,it's really helpful

-

04-24-2009, 01:14 PM #17

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 112

Water Table Hints

A fer hints when building water tables.

1) Make clean out holes in the top of the air chamber. The slab andcut residue will slowly mak its way into the lower chamber anbd reduce the volume. This will effect how high you can raise the water level.

A round or oval hole with a cover plate and gasket work well.

2) Limit the feed Air Pressure to the bladder section. The more Volume you have the faster the water will rise. Too much air pressure and you can possibly have a blow out on the tank sides or top.

3) The easiest Raise/Lower Controls would be an air valve controlling the Compressed Air into the bladder section. Tihs will force air into the bladdrer and expel the water, raising it.

A second Air Valve from the bladder (Near the top of the table) will release the air pressure and lower the water level. Vent this pipe back into the table as some trapped water will also blow out with the air.

4) Add buckets to the deep side of the table. When cleaning you just push the slag into the buckets and lift out with a crane or fork lift. This beats shoveling out a full table.

Good Luck,

Alan Bradford

Plasma Technologies

Canaan NH

www.plasmatechnologies.com

-

04-24-2009, 08:56 PM #18

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 66

Just a quick thought about water tables with inverted tanks inside. We had a customer in the UK who started cutting quite a bit of aluminium, the dross, as you would expect, fell into the water and combined with the oxygen in the water releasing hydrogen. This collected in the inverted tank and started to leak out of a small hole in the top plate. The customer noticed the leak (it had been leaking for some time) and decided to weld it up. The resulting bang was heard for quite some distance, the operator who was stood on the bed top had his ankles shattered and the small inverter welder was shot through the roof. I think it is best to bubble air through the water should you ever cut aluminium on a bed like this.

Cheers

Mike

Techserv

Similar Threads

-

water jet cutting is really cool

By webcruiser8 in forum Waterjet General TopicsReplies: 17Last Post: 05-16-2015, 07:20 AM -

Water Jet cutting Specs needed......

By PoppaBear10 in forum Plasma, EDM / Other similar machine Project LogReplies: 1Last Post: 03-11-2009, 05:13 PM -

Water jet cutter cutting 2mm thick SS.

By alexccmeister in forum Uncategorised MetalWorking MachinesReplies: 1Last Post: 10-14-2008, 05:52 PM -

Plasma/water/lazer cutting

By ty1295 in forum Employment OpportunityReplies: 4Last Post: 10-15-2006, 01:36 AM -

Video of water cutting machine

By ynneb in forum Waterjet General TopicsReplies: 9Last Post: 03-04-2006, 01:32 AM

Reply With Quote

Reply With Quote