Hi All,

I was wondering how many of you that have it, use the CAS on your machines?

There was a lot of hype around it while we were looking at the multus (which we did eventually buy). Our tooling suppliers told us that they had models of all their tools, so it would be very simple to load these into the machine.

We've had the Multus now for nearly a month (and tooling) but have not received said files, which is annoying.

I personally feel that CAS is a gimmick, and this was reinforced when one of the Okuma reps mentioned while installing, that it would not stop the turret from a crash while positioning thru it's 180 deg range.

Hearing this, I feel the time spent building up the chuck jaws, part, and tooling, could be left out of my set-up times. I'm not perfect at all. I make mistakes in my programmes all the time, but I find them while proving out the job, and haven't crashed a machine in over ten years.

So..., do you guys use it?

Will it stop the turret before hitting anything?

Will I sleep better knowing the afternoon shift can't hurt it, if left to finish a set-up?

Thanks for listening.

Dave.

ps. here's a link to a video of our first job done on the Multus!

[ame="http://www.youtube.com/watch?v=5v--O8DTcTo"]YouTube - Multus Screw[/ame]

Thread: Collision Avoidance System

Results 1 to 20 of 33

-

04-18-2009, 01:51 PM #1

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 142

Collision Avoidance System

-

04-19-2009, 12:08 AM #2

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 9

Hi,

Firstly Good choice on the Machine, we love our B400W

With regards to the CAS our application engineer switched it off when he installed the Machine & stated it was very time consuming to put all the relevant info in!!!

I have had a play with it but I have never switched it on & I probably won't, we do a lot of prototyping on it & it's just something else to add to the lengthy set up time!!!

With the tool models Sandvik have links on their website, we used them for drawing the tools up in Mastercam

Jason

-

04-19-2009, 12:48 PM #3

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 142

Hi Jason,

We too, will be doing prototype work and small batch runs, mostly.

We dont want to spend too much time setting up, and I think preparing the CAS will be a big part of the set-up time.

If long production runs are the norm, then I still dont see any need for it. Whats going to happen?

It's a catch 22.

-

04-19-2009, 08:43 PM #4

Member

Member

- Join Date

- Mar 2009

- Posts

- 1982

When I install the lathe, I start training with security items first. My students know chuck and tailstock barrier before they start to cut soft jaws.

There are 4 ... 6 Multus of MacTurn machines at Okuma headquarters in Krefeld constantly for repair after collision. If in case, it means instant bankrupcy to our small customers.

Do You catch my idea? If some machine seller engineer says, that You don't need japanese designed safety system, he probably wants to earn some extra on repair after collission. Or colission. Or colisionn, sorry for my English :-)

It very simple, however. I can't imagine working without CAS.

-

04-27-2009, 12:54 AM #5

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 372

___________________________________________

I personally feel that CAS is a gimmick, and this was reinforced when one of the Okuma reps mentioned while installing, that it would not stop the turret from a crash while positioning thru it's 180 deg range

___________________________________________

Dave,

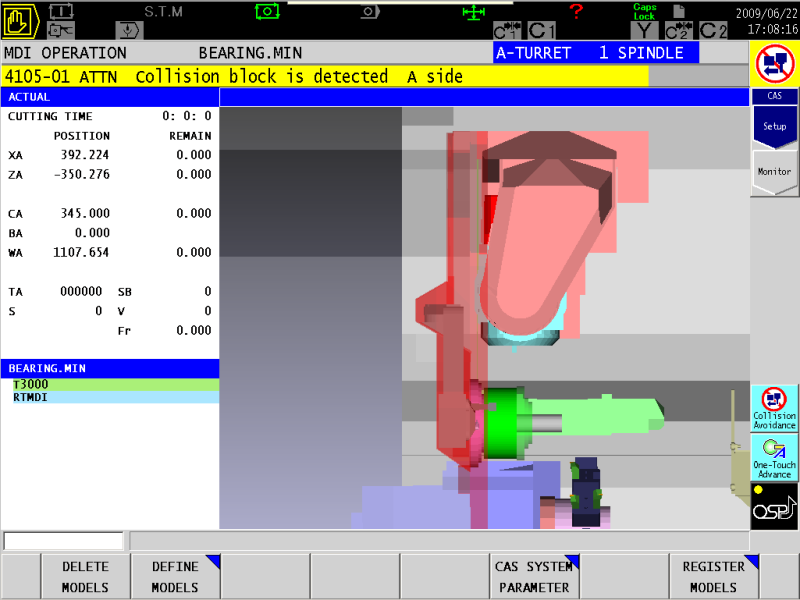

You are totally incorrect here, CAS will check B axis turret movement through the full range of 210° If you spent the 10 mins to set it up it can and will save you many hours of potentailly lost production

So..., do you guys use it? --------------------- Yes you bet

Will it stop the turret before hitting anything? ---------------- Absolutley it will

-

04-27-2009, 01:19 PM #6

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 142

Hi guyz, thanks for your responses.

I've decided to spend the time and get into using the CAS. I don't feel I could explain to the boss why his new m/c has been crashed, when it has the capacity to prevent it.

I have to say that Okuma have done their best to make a control that is not user friendly. Nothing in it is intuitive, and there is a lack of continuity in it's processes.

The .stp files that Sandvik offer on their website are not compatable. They need to be converted to .stl files, and then modified still further to make them usable. I spent all day today with our Okuma rep (G'day mate) trying to get six tools and chuck/jaws/billet setup. He was still going when I left for home.

Our machine has spent the last week being stripped and rebuilt (twice) to re-align the turret.

CAS would not have prevented this.

If a swarf ring that is left from boring a thru hole happens to jam itself into the GAP between the jaws and the tool tip, then that's bad luck. This has happened to me before (on conventional turret m/c's) with no greater damage than a busted insert and or, shim.

So that's what happened on our multus, and it's a HUGE DRAMA! We went back thru the MACMAN and found no overloads, no E/stops, nothing to suggest anything drastic has occured. No damage to jaws, or part. The tool has a mark under the corner of the shim which looks just like what it is, the result of a tip and shim breaking, which is what the operator said happened.

I cant say for sure what really did happen because I wasn't there.

I know I'm having a rant here. It's getting frustrating to still be setting up this machine weeks after it was bolted down. We haven't even started on the bar feeder yet!

-

05-01-2009, 09:02 AM #7

Member

Member

- Join Date

- Mar 2009

- Posts

- 1982

Okuma have done their best to make a control that is not user friendly. Nothing in it is intuitive

so, you didn't worked with Deutsch made software yet

Okuma is japanese origin, and it's the one amongst very few of them, what's possible to translate into other languages.

After some months of working with Okuma You'll love it and it's interface. Everything is on right place there, it has all it needs to and it hasn't any hassles to get lost between.

-

05-31-2009, 11:18 AM #8

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 142

Sorry about the broken video link at the head of this thread, this should work...

[ame="http://www.youtube.com/watch?v=asG5DL0y1AE"]YouTube - Multus Screw[/ame]

-

06-17-2009, 04:43 PM #9

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 17

CAS..... oh dear

It will stop from crashing a tool during turret rotation, but it will not stop the back end of itself from hitting anything, as one customer found out when the back end went through the main spindle guarding. lol

I like the Multus, it is a very versatile machine. It has a couple a flaws though.

1. Turret is soft, very soft, I have done countless alignments on B-axis turrets from minor crashes. If you have to open one up, you will find that the only thing holding the turret to the curvic coupling is the brass worm gear held on by 12 M8 bolts done up to 16Nm. not very tight. I gave up on just aligning the turret by rotating it on the 8 Cap heads you can see. It is easier of course, but what I found is, this is not the place where it moves, no matter how soft you think it hits. The weakest point is the brass worm threads which open up after a hit and become even looser. Try it yourself if you dont believe me, I guarantee your turret will be out again on the next decent cut you take. The only way to do it properly is to straighten the plate bolted to the worm ring via taper pins and re touqeing the bolts.

2. Spindle gets run out very easily after a knock. If tip blows out in a cut, it will not pull up in time with load monitoring. This will cause runout on spindle.

If there is more than 15um runout on the spindle, I cannot align turret within factory specs. (remember the spindle will index to different positions depending on tooling and main/sub spindle).

3. heavier crashes will move the linear guides on X and Y. If this happens, you will be definitely be getting a spindle runnout problem and B-axis alignment

My advice, is anyone who owns a multus, get a test bar at least 150mm long (8inches for you seppos) and check runout immediately. It is possible to realign runout by tapping the back preload nut. What I have found is that the back tends to run out much more then the front after a knock. Remember that the rotary coupling is on the back and is not somewhere you want coolant leaking and if that happens, you will be up for a much bigger repair bill for replacement bearings.

small knock=turret alignment=1 day

medium knock=spindle alignmet+turret aligment=3days

big knock= spindle alignment+turret alignment+x/y linear rail alignment=1 week

continuing with run out=bearing replacement=2 or 3 weeks

-

06-17-2009, 05:55 PM #10

Member

Member

- Join Date

- Mar 2009

- Posts

- 1982

but it will not stop the back end of itself from hitting anything

Maybe there are different versions. I have seen several times on three different Multus'es how CAS works watching the back.

-

06-21-2009, 11:35 AM #11

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 142

Gday kkungfu,

I've read your post with much interest!

Our Multus is very green with not many hours on it, but has just had the turret re-aligned for the 2nd time. Our Okuma guys insist that it has had a serious knock each time, but they would have to say that.

Both times, the problem was found during the day shift. Both times, arvo shift swear nothing happened except for blowing a tip in cut.

Maybe you should let Okuma know about your "down" times! We've lost the machine for a week on each occasion, with them doing the work.

I can't say I've tried to wack the back of the turret into a guard, but the CAS does stop it when near the sub jaws or chuck.

Okuma have said to use the load monitor, use the load monitor, use the load monitor, but run 3 parts in auto set mode, before letting it into actual monitoring mode. So what happens if a tip blows in the first 3 parts?!

On a side note: anyone in Australia thinking of getting a barfeeder supplied by Bartec should do so knowing that they are cowboys. They dont have a knowledge of their own product or how they should integrate with your machine, as well as producing some very poor quality components. Be warned!

-

06-21-2009, 03:06 PM #12

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 17

CAS will stop it if is traveling in a linear motion, but CAS wont stop during turret index. I've seen it up close to the limit in Z- minus and index into the wall!!!

They took a week?!?!? did they have to align the linear rails? If it was just the turret, I have that done in a day!

PM me if you want, I could tell you a bit more.

PS:I dont work for Okuma

-

06-22-2009, 05:49 AM #13

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 372

-

06-22-2009, 06:22 AM #14

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 17

-

06-22-2009, 07:54 AM #15

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 372

-

06-22-2009, 08:55 AM #16

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 17

Good stuff, yours works, wish the one I had to fix did that.

-

06-22-2009, 12:22 PM #17

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 372

-

06-22-2009, 02:05 PM #18

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 17

Perhaps, i don't normally show ppl how to turn it off, and he didn't know how to.

Don't know why it did it, machine was only a week old.

-

06-23-2009, 01:51 AM #19

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 372

Well basically the only way to run the back of the spindle into the headstock guarding is to have the CAS off Simple as that really. Just out of interest how did you come to be working on a one week old machine?

-

06-23-2009, 12:56 PM #20

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 142

They took a week?!?!? did they have to align the linear rails? If it was just the turret, I have that done in a day!

Working on the B axis only. They can get the turret off and on twice in a day! Maybe they should take a bit more time cause the o-rings got pinched and it leaked like a sieve, so they all got replaced.

Similar Threads

-

CNC Servo Retrofit using G320's - Rathole avoidance.

By KSky in forum Gecko DrivesReplies: 0Last Post: 03-13-2014, 09:24 PM -

Collision Avoidane System on Multus

By Tyros25 in forum OkumaReplies: 0Last Post: 01-22-2014, 03:29 PM -

Collision Avoidance System and Sandvik's STL Files

By Tyros25 in forum OkumaReplies: 6Last Post: 11-20-2013, 09:18 PM -

Multus Crash Avoidance

By dws35 in forum OkumaReplies: 3Last Post: 01-31-2011, 11:44 AM -

MULTUS B400-W. Positioning .stp .stl 3D tools into Collision Avoidance System.

By BarnabyRudge in forum OkumaReplies: 9Last Post: 04-08-2010, 01:08 PM

Reply With Quote

Reply With Quote