hello fellas,

newbie here and looking for help.

i recently purchased a sherline mill and need to some advice. my first projects need to me to fly cut the surface and bore some holes. i know sherline sells these accessories but i want to use a bigger fly cutter and want to use a different boring head.

any suggestions for the fly cutter and i saw a Criterion boring head, would that work on my mill?

so far, the sherline looks like a well made machine, but it seems like im "stuck" only to use their accessories, am i wrong?

thanks again!

Thread: Sherline Mill Help

Results 1 to 7 of 7

-

05-18-2009, 03:17 PM #1

Registered

Registered

- Join Date

- May 2009

- Posts

- 5

Sherline Mill Help

-

05-18-2009, 03:26 PM #2

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 3655

Hi DrBadWrench. Welcome to the Zone!

You are only "stuck" by the size of the mill. Size of cut depends on the rigidity of the mill. This tiny mill can only handle small tooling. R8 tooling will not fit this spindle,

Much of the Taig tooling will work with the Sherline mill.

http://www.cartertools.com/

CR.

-

05-18-2009, 09:39 PM #3

Registered

Registered

- Join Date

- May 2008

- Posts

- 26

Sherline mill help

Although the mill is small, and aluminum; it is a capable machine if used properly. Obviously smaller work, and of plastics or soft metals are best. I have added an ER-25 collet head to my spindle, and the collets can grip anything up to and beyond 1/2" IIRC. This being the case there should be many available fly cutters with a 1/2" shank. I made a block to hold the QCTP toolpost on my Sherline lathe, and fly cut it with the Sherline mill using the standard Sherline flycutter, and it cut like a dream, with the part near mirror finish.

I use my Sherline's here at work to build fiber optic connector cleaning heads, daily. When you have any other questions, fire away.

-

05-19-2009, 04:34 AM #4

Registered

Registered

- Join Date

- May 2009

- Posts

- 5

thanks for the input fellas.

most of my projects are "small" and i think the sherline lathe/mill will suffice. IF i had the room in the garage, i would of gotten something bigger, but for now, the sherline will have to do.

any recommendations for a boring head and or bars?

i will look into the collet head mentioned.

thanks again fellas!

-

05-19-2009, 11:33 AM #5

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 445

You are going to run into the practical limits of the machine if you try and run tools much bigger than Sherline sells. Not only is the rigidity of the mill at issue, but the motor in the head as well. It's simply not powerful enough to swing big tools.

It's not all bad news, you can get a whole lot of work done with the Sherline stuff, or the Taig or A2ZCNC equivalents. More smaller passes is the name of the game with a machine like this.

-

05-20-2009, 02:57 AM #6

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 474

I'm really happy with my Sherline mill, and the indexable carbide single-point flycutter they sell. That being said, with smaller passes, even a homebrew flycutter works well, when you need to cover a larger area.

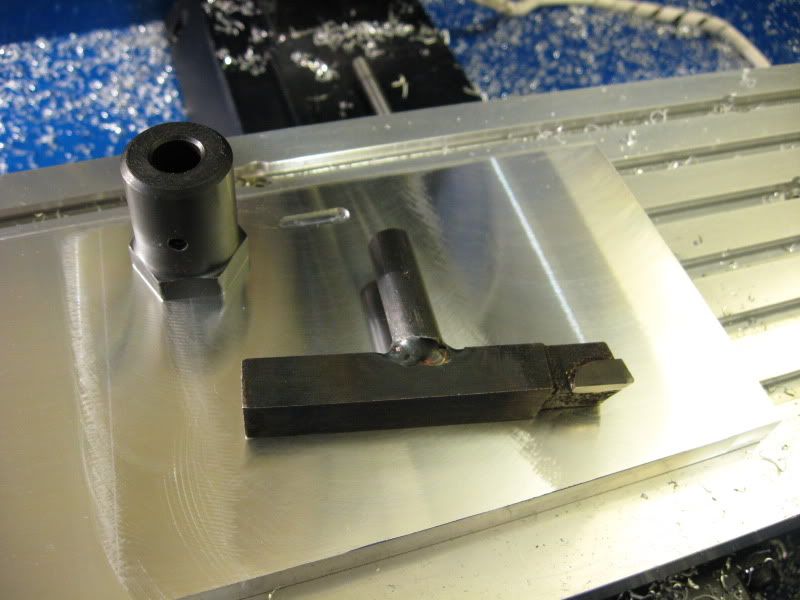

Also, A2Zcnc's toolholders are quite handy, this one's a 3/8".

-

05-25-2009, 11:01 PM #7

Registered

Registered

- Join Date

- May 2009

- Posts

- 5

thanks for the info fellas.

i bought an import boring head for my mill, but the holes are set up to accept 1/2" boring bars. is there an adapter (sleeve?) that would allow me to run 3/8" boring bars in the same boring head?

maybe this should be a project for me and my lathe instead of buying one?

thanks again.

Similar Threads

-

Sherline CNC mill

By solskov in forum LinuxCNC (formerly EMC2)Replies: 1Last Post: 01-04-2009, 01:39 PM -

Sherline CNC Mill

By rgreenfield in forum Benchtop MachinesReplies: 4Last Post: 02-03-2008, 11:47 PM -

What Sherline Mill Accessories To Buy And When?

By Too_Many_Tools in forum Benchtop MachinesReplies: 6Last Post: 10-13-2007, 05:59 PM -

My Sherline CNC Mill

By Coetzee in forum Benchtop MachinesReplies: 0Last Post: 04-07-2007, 04:44 AM -

Help with Sherline Mill

By kellogs72 in forum Benchtop MachinesReplies: 5Last Post: 11-05-2005, 06:30 AM

Reply With Quote

Reply With Quote