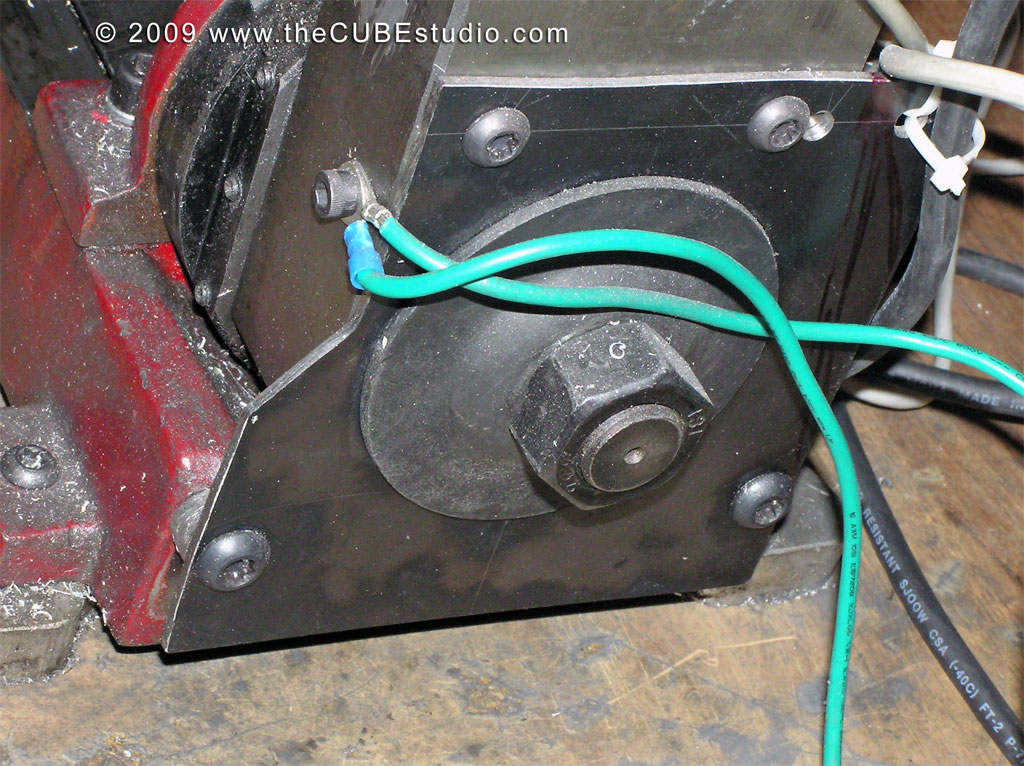

I was asked in another thread to post a photo of my column brace. Makes more sense to make a new thread for it.

1/8" thick mild steel bolted to the column and the base. SPacers needed on base bolts. Column can be tilted by removing two upper bolts.

Without this brace, I coulnd barely cut aluminum with a 1/4" endmill. With the brace, I can run a 4" diameter fly cutter as seen in this video.

Note: fly cutters typically are making interrupted cuts. This can shatter the plastic gears in a stock X2 head. I would not reccomend this without the belt drive conversion.

[ame="http://www.youtube.com/watch?v=8y-C59aF-ac"]YouTube - Machining Aluminum with Fly Cutter on X2 with Mach3 control software[/ame]

Results 1 to 8 of 8

-

08-17-2009, 11:40 AM #1

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 165

X2 Mini-Mill Column Brace (photo & video)

-

08-17-2009, 01:20 PM #2

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 43

Good idea. I will likely do the same. Funny thing was that I had an issue like yours. I just tightened the bolt some more since it was barely snug and noticed a world of difference.

Any thoughts on using some engine block filler to further stiffen the column? I have some lying around.

Oh by the way, I found your videos to be mesmerizing! I have a long way to go...

-

08-17-2009, 01:47 PM #3

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Looks good.

Really just about anything added would do a better job than the as shipped X2. Filling the column, adding stiffner to the back, bracing the full column etc are all steps in the right direction. There are quite a few ways guys have done this here at the Zone.

Personally when I used my X2 in manual mode, I never saw the use for the tilting feature of the column. It throws out the weight and does odd things to the dovetails. If one really needed the tilting feature, it should be added as an addition like the well clad Hoss X2 Freak.

I choose not to convert an X2 for my first mill and feel it was a good decision.

Now I really need a second mill that would just cut small aluminum parts. I am leaning toward using what is left of my X2 and 7-12 lathe.

The column would certainly be the first issue I address.

Nice work and machine. Got her tuned up real nice.Lee

-

08-17-2009, 02:07 PM #4

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 165

In my opinion, there is a reasonable limit to how much column stiffening is useful on an X2 because the rest of the machine is also light weight.

It is a pretty tough little machine though . . takes a lot of abuse. Using a full size mill vice helps the X2 a lot just because of the mass it adds to the table.

The current task for my little beast is a test bed to evaluate servo drives for the 4th axis and for my next X3 project, then I'll be done with the X2 and sell it.

-

08-17-2009, 02:52 PM #5

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 121

Thanks alot for posting that pic up!

I'm planning to make something like that too.

I bet you'll never sell your X2! You're probably more likely to turn it into a CD polishing device than sell it...

-

08-14-2015, 01:52 AM #6

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 51

-

08-14-2015, 02:56 PM #7

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: X2 Mini-Mill Column Brace (photo & video)

Wet noodle?

Lee

Lee

-

08-14-2015, 09:41 PM #8

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 51

Similar Threads

-

Cutting out the column cross brace

By skray775 in forum Charter Oak Automation Support ForumReplies: 11Last Post: 12-26-2011, 04:42 PM -

Another x2 column brace (different)

By luv2ride in forum Benchtop MachinesReplies: 29Last Post: 06-15-2011, 12:40 AM -

mini mill DOC and column question

By cstrickland in forum Benchtop MachinesReplies: 9Last Post: 05-22-2011, 10:46 AM -

mini-mill z-axis/column rigidity

By knudsen in forum Benchtop MachinesReplies: 5Last Post: 02-10-2010, 10:51 PM -

X2 Column Brace Idea

By mrcodewiz in forum Benchtop MachinesReplies: 6Last Post: 03-21-2008, 02:38 PM

Reply With Quote

Reply With Quote