I'm looking for a milling spindle that can work in the range of up to 3000-5000 RPM. I've got a high-speed spindle installed on my DIY 8020 aluminum machine, and I find it somewhat limiing, for ex. I can't do any facemilling and I can't use any bits that are larger than, say, 1/4" (on metals, I mean).

I've seen some people mention using servos as a spindle motors. Has anybody done that? How's this work?

Another thing I'm considering is getting the head assembly from littlemachineshop or Sherline (P/N 6513, 6514). However, Mini Mill assy seems to have a dovetail (which I don't actually need) ,and Sherline doesn't give any dimensions of its headstock.

Any ideas?

Thread: Low-speed (rpm) spindle wanted!

Results 1 to 14 of 14

-

11-09-2009, 11:25 PM #1

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 83

Low-speed (rpm) spindle wanted!

My DIY CNC router plans at www.8020CNC.com

-

11-10-2009, 05:12 AM #2

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

http://littlemachineshop.com/product...ory=-269978449

Why not get this one and add a pulley, motor and controller? I'm not sure if you can do that though - I don't know what the other end of the spindle looks like.

-

11-10-2009, 09:50 PM #3

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 83

jsheerin,

That's exactly the problem I'm facing right now! I saw that block but I can't find enough details about it to make any assumptions...My DIY CNC router plans at www.8020CNC.com

-

11-10-2009, 10:03 PM #4

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

I think it would be possible - see pic's here:

http://www.cnczone.com/forums/showpo...8&postcount=43

http://www.cnczone.com/forums/showpo...3&postcount=57

Info here:

http://www.cnczone.com/forums/showpo...5&postcount=82

Or maybe email the littlemachineshop people and ask them about it. Maybe they could take another picture for you of the other end. Alternatively, look at www.grizzly.com. They have parts manuals for some of their machines with exploded views. You can also order replacement parts.

-

11-10-2009, 10:07 PM #5

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

Or better yet, look here:

http://www.fignoggle.com/workshop/ar...version-part-1

-

11-10-2009, 10:16 PM #6

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 83

Yeah, this looks like a it can be built relatively easy.

Do you know of any source for not-very-heavy DC motors to run the spindle?My DIY CNC router plans at www.8020CNC.com

-

11-10-2009, 10:35 PM #7

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

Sorry, I don't know many sources in Russia... Personally I would run a 3ph motor with a VFD, but that's because I have piles of small VFD's sitting around and low power 3ph motors are fairly cheap. They're not very light though... The usual suspect for things like this are surplus treadmill motors. I have one that's rated for 2 or 3HP and it's a bit lighter and smaller than the 1/2HP 3ph motor I have on my lathe. I got it from tearing apart a dead treadmill.

-

11-13-2009, 08:29 PM #8

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

I forgot we have one of these small bench mills at work. I was looking at it today and it looks like it should not be a problem to modify. So I bought one of the heads from Little Machine Shop to build a drill head for my router. I'll post some pics when it shows up.

-

11-14-2009, 02:51 AM #9

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 558

Hi there,

This might be a bit late to be much use, but here's a spindle made up by mounting a servo to a live tool off a big CNC lathe. It was actually intended to be switched between the lathe and a mill, but hasn't made it to the mill yet The speed range is up to 4500 rpm, and it just uses the Mach3 step/direction spindle output for control. A nice thing about using the servo might be the ability to use the index pulse from the encoder for threading in Mach3 Turn.

The speed range is up to 4500 rpm, and it just uses the Mach3 step/direction spindle output for control. A nice thing about using the servo might be the ability to use the index pulse from the encoder for threading in Mach3 Turn.

There's a little more about it here - http://zealcnc.wordjot.co.nz/posts/the-micro-lathe/

Best regards,

Jason

-

11-15-2009, 06:05 PM #10

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 83

jsheerin,

If you can post pics that would be of a great help to me!

Jason,

Is the motor directly coupled to the tool holder? Have you milled anything with it yet?

Meanwhile I'm researching a possiblity to control my spindle motor (it's a universal collector motor) with something like a KBIC. Like this one:

http://www.galco.com/scripts/cgiip.e...%20ELECTRONICS

Does anybody have any experience with those?My DIY CNC router plans at www.8020CNC.com

-

11-15-2009, 10:21 PM #11

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 558

Ilya, yes - it's coupled directly to the back of the tool holder. It was originally a new right angle drive type that was rejected due to a flaw in the drive gear. I removed the gears and replaced the bearing retainer nut with one I made with spider type coupling fingers. I haven't milled anything yet, but I have used it for turning - it works pretty well. It could do with a bit more power for parting stainless steel, but a bigger servo should fix that.

Best regards,

Jason

-

11-21-2009, 08:08 PM #12

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

As promised, here are some pics of the mini mill head. I got the R8 taper spindle and a drill chuck and set of collets with mine. I plan on using it as a drilling and milling head. I'm going to try using a DC treadmill motor to drive it with a timing belt. The head by itself weighs 5.48kg, and the drill chuck weighs 1.04kg. I haven't been able to remove the nut from the rear of the shaft so far, but can post more pics when I do. If anyone has tips for how to get that off without scratching up the shaft, I'm all ears.

-

11-21-2009, 08:18 PM #13

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

Answered my own question - apparently the mill comes with two different spanner wrenches to fit the nut and the spacer on the top (back - whatever) of the head. As shown in the fignoggle link above:

Also, the head doesn't come with a draw bar, so you'll have to make your own.

-

01-13-2010, 10:52 PM #14

Registered

Registered

- Join Date

- Sep 2008

- Posts

- 83

jsheerin,

Thanks for the pics! Sorry for being way too late - I haven't received a topic reply notification for some reason.

Anyway, thoe head looks cool. It's a bit heavy though. And when you add a motor to that it will end up more than 10-12 kg I guess... Mmmm... Don't think my router will like it.

Btw, I've ordered a KBIC motor controller and hooked it up. The torque still drops at low RPM but not as bad. I'm going to get a tacho and to measure the loaded/unloaded motor RPM. And there's some facemilling due...

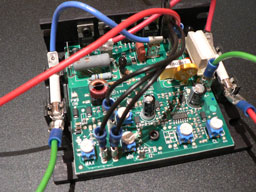

This is the controller:

Vandalized router motor. I removed the speed control circuit and connected the controller directly to the motor:

My CNC plans at www.8020CNC.com

Similar Threads

-

Wanted Lathe, oil field and hollow spindle

By nemco in forum Want To Buy...Need help!Replies: 0Last Post: 09-14-2008, 04:33 PM -

Spindle Speed

By mikemill in forum CNC (Mill / Lathe) Control Software (NC)Replies: 0Last Post: 01-04-2008, 05:09 PM -

Spindle Speed

By teenrocketnerd in forum DIY CNC Router Table MachinesReplies: 1Last Post: 06-20-2007, 11:59 PM -

spindle speed

By Mike Boarman in forum Machines running Mach SoftwareReplies: 0Last Post: 11-28-2006, 04:37 AM -

BPSeriesI / Centroid control- Spindle speed all out of whack with speed dial?

By peter.blais in forum Bridgeport / Hardinge MillsReplies: 9Last Post: 08-08-2006, 09:29 AM

Reply With Quote

Reply With Quote