Hi all,

Well...going to try to be short, long stories take time

Yesterday i been trying to make a buying list of tools i am in great need of, such as attachments for my dremel 300, and at the end of the list i was quite disappointed. Dremel is such a neat tool, but problem is, to do some precise work you need to get several attachments and my disappointment was at the total price, which is a little sour for what you get regarding variety/precision per $$$ imo

I am pc enthusiast and i think i would love to have a little cnc. Problem is, shipping parts to brazil is very expensive, indeed unafordable. I like electrical wiring, and i would love to even make a nice sleeving on the wiring too.

One of my friends here works with cnc maintenance and he said he can get very good step motors for a bargain price.

To begin with, i will use my dremel to route, and my main goal is to drill through acrylic and wood neatly. If possible too i would like to drill to soft metals, like alum. for example. However i believe that drilling through soft metals will require better spindle machine, different table top and so on, right?

I also seen that there is option for linux cnc softwares, which is great. The more open-source it can be, the better it is for me.

are there any open-source available for download?

a blueprint ready to be cut on a cnc?

Budget: 500 USD

MDF shoud be strong/ cheap enough to start with???

Or it it cheaper/lighter with aluminium frames, like those from windows or sliding dors

I need to put together:

Cutting Area:

- (x) 28" not mobile bed

- (y) 28"

- (z) 15" ??? - what is the maximum Z should travel? Dont need it be to tall

my friend said that he found 3 very fast and cheap step motors! and i need this little cnc to be precise and accurate

Thread: OPEN SOURCE BLUEPRINTS?

Results 1 to 8 of 8

-

02-19-2010, 06:09 PM #1

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

OPEN SOURCE BLUEPRINTS?

-

02-19-2010, 06:59 PM #2

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 272

Welcome to/from a newbie

Welcome to the Zone.

I can only offer limited advice, as I am a newbie & have not built a machine. So take my advice for what it is, a newbies view.

As far as the Dremel is concerned, it will cut acrylic, wood and maybe even drill holes in aluminum. A small trim router may be a better choice, depends upon YOUR needs. IMHO, shorter (less travel) for the Z-axis is usually better (more rigid). Do you really NEED 15" of travel? Many things determine the machines capabilities. The thing is that ALL machines are a series of compromises, speed Vs. accuracy, cost Vs. size/rigidity, design Vs. ability to build such design, etc. Many have built MDF and aluminum extrusion based machines (that meet THEIR needs), however, every design and material choice affects overall machine performance characteristics. You first need to determine what you want you machine to be capable of doing and how well you want it to do it.

Characteristics you need to consider/determine:

1) Speed of machine, feed rate, jog speed

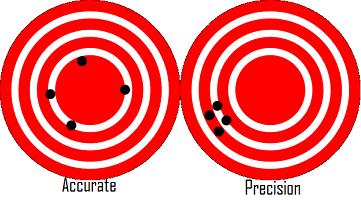

2) What tolerances are acceptable, (accuracy & precision)

3) Budget constraints/parts availability

4) Tools available & your skill level for the build

These are some of the things you must consider prior to designing YOUR machine.

My advice is to do your "Homework". You have come to the right/best place to do that homework, the tutors (members) here are great. Here at the Zone, the true "Experts" are willing to answer your questions, but you really should do your homework (research the zone and learn)first.

Just another newbies uneducated :withstupiinsights. Best of luck.

Randy,I may not be good....

But I am S L O W!!

-

02-20-2010, 03:05 AM #3

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

-

02-20-2010, 06:07 AM #4

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 272

Design critique: from a newbie

Design critique: from a newbie

Denis,

A few design critiques for you to consider:

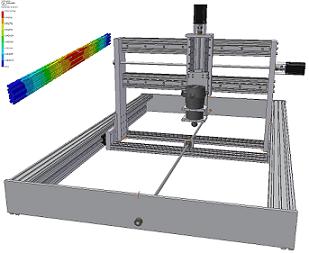

1) You may want to invert the X-axis rack (teeth pointed down) and relocate it to the outside of the X-axis rails, it will be less prone to collecting dust & debris.

2) Unsupported Y-axis rails may be too flexible, Supported rails WILL increase rigidity, allowing for more accuracy & precision. (consider utilizing a torsion box design)

3) Increasing the width of the base for the Gantry uprights should help reduce potential racking.

4) Need to secure Gantry uprights to the x-axis somehow, to prevent cutting forces from lifting up the whole y-axis.

Also, don't settle for 0.1" Accuracy & Precision, .001" to .005" tolerances are obtainable from a DIY build.

BTW, nice job on the 3D modeling. The ability to utilize 3D/CAD software is crucial to success in the world of CNC and I can see that you are well on your way.:cheers:

Randy,I may not be good....

But I am S L O W!!

-

02-20-2010, 03:05 PM #5

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Thanks Randy,

will make sure i consider your critiques!

-

03-04-2010, 12:00 AM #6

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Has anyone seen any .skp plans?

I am way more comfortable working with sketchup and perhaps if there is a cnc plan with similar sizes that i need, perhaps i could modify it?

Any other ideas?

Where can i buy cheap starting cnc kits?

I know that many ppl here (DIY enthusiast) also have pretty good electronic skills. I have seen that some members here make their own controller boards, power supplies and so on.

I am stuck on my build because i have no idea how strong the step motors have to be.

Would it be better if i bought a kit that includes all electronic boards, power supply, step motors all together?

I also seen many cnc designs that use the V (90 degree) sliding mechanism but i also seen many that have a simple U shape (something similar to sliding drawers). Which one is best/cheapest to make?

Size:

X axis: 28"

Y axis: 28"

Z axis: 5"

mobile gantry and not sliding bed. I need this to cut mostly through acrylic, plastics, and rarely through very thin alum sheets (0.6mm to 1mm thick).

My aim is to build a fast routing machine that can do major work fast (if possible) and precise and accurate as a PCB engraver, so i can transfer engraving design onto acrylic panels.

Please help me out!

-

03-04-2010, 12:20 AM #7Patience and perseverance have a magical effect before which difficulties disappear and obstacles vanish.

-

03-05-2010, 02:04 PM #8

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Thanks mate, i think this is just what i needed! Will get in touch with the site owner soon!

Similar Threads

-

Open Source Cad Cam

By kch in forum CNC (Mill / Lathe) Control Software (NC)Replies: 1Last Post: 08-30-2007, 12:51 AM -

Open Source X2 CNC Conversion

By ignatz in forum Open Source CNC Machine DesignsReplies: 0Last Post: 03-12-2006, 11:40 PM -

BEST Open source Controller ?

By Seventeen in forum Open Source Controller BoardsReplies: 12Last Post: 09-22-2005, 12:27 AM -

What's in work at the open source

By pminmo in forum Open Source Controller BoardsReplies: 0Last Post: 02-13-2005, 08:55 PM -

Web space available for open source cnc

By ShayArnett in forum Open Source Controller BoardsReplies: 1Last Post: 01-11-2005, 04:31 PM

Reply With Quote

Reply With Quote