GF Machining Solutions

Products

Passion for Precision

Electroerosive and electrochemical machines

Wire spark erosion machines

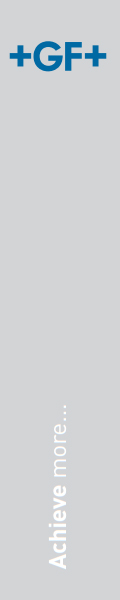

CUT X 350/550

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

Extreme accuracy:

The optimized mechanics, the new heads with 3D printing design and the AI-based thermal management form the basis for unprecedented accuracy and surface quality.

Simple:

Easy and flexible to use for both experts and beginners. Thanks to collision protection, wire annealing before threading, a new HMI and the ability to switch from open to closed guides in minutes.

Fast:

We work unbeatably fast with the Intelligent Power Generator with Direct Power Supply (IPG-DPS) and the unique Twin-Wire technology.

Translated with DeepL

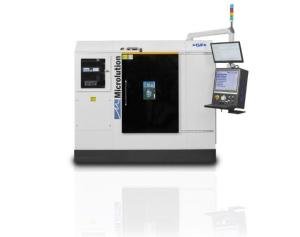

AgieCharmilles CUT 1000

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

The new AgieCharmilles CUT 1000 GF machining solutions specifically designed to meet these requirements. They are characterized by unique features in perfect precision and productivity, predictability and repeatability of the processing results. This wire erosion machine sets new standards in the micro erosion.

Thanks to its exclusive machine concept the AgieCharmilles CUT satisfies the 1000 highest overlooking the positioning accuracy, as well as the moulds and detailed precision. These results through the development of an innovative machine tools design based a monobloc frame with separate X and y axes as well as static and dynamic analyses of the behaviour of the machine of tool are possible for the finite element method.

This description was translated from German to English by "Bing Translator".

AgieCharmilles CUT 1000/2000 OilTech

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

The new AgieCharmilles CUT 1000 OilTech GF machining solutions specifically designed to meet these requirements. They are characterized by unique features in perfect precision and productivity, predictability and repeatability of the processing results. This wire erosion machine sets new standards in the micro erosion.

Thanks to its exclusive machine concept the AgieCharmilles CUT meets 1000 OilTech highest overlooking the positioning accuracy, as well as the moulds and detailed precision. These results through the development of an innovative machine tools design based a monobloc frame with separate X and y axes as well as static and dynamic analyses of the behaviour of the machine of tool are possible for the finite element method.

The machining accuracy is the result of a set of technological components, such as the mechanical concept, the editing process or the wire Guide. Each component of the AgieCharmilles CUT wire erosion machines was designed in every detail with the sole aim and implements, a high accuracy over the entire service life of the machine to make sure 2000 OilTech.

Only a wire management system enables the use of all wire diameter of 0.05 to 0.30 mm. This exclusive feature of wire erosion machines AgieCharmilles CUT 2000 OilTech is no coincidence. The concept of all components involved in the wire run is based on long experience of engineers from GF machining solutions with views of high accuracy and the great flexibility of use. No additional costs incurred when a different wire diameter for producing a new tool is needed. The use of a different wire diameter requires no additional adjustment.

This description was translated from German to English by "Bing Translator".

AgieCharmilles CUT E 600

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

| 600 x 400 x 350 mm |

The AgieCharmilles CUT E 350/AgieCharmilles CUT E 600 range puts efficiency at the touch of your finger with a smart, easy-to-use human-machine interface (HMI) and onboard technologies that streamline your job setup, improve your cutting speed, improve your surface finish, protect your valuable workpieces, and ensure your process robustness.

CUT E 350

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

| 350 x 250 x 250 mm |

The AgieCharmilles CUT E 350/AgieCharmilles CUT E 600 range puts efficiency at the touch of your finger with a smart, easy-to-use human-machine interface (HMI) and onboard technologies that streamline your job setup, improve your cutting speed, improve your surface finish, protect your valuable workpieces, and ensure your process robustness.

CUT P 350/ 550/ 800/ 1250

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

In the age of the Internet of things presents GF machining solutions smart consumables with integrated RFID chips in wire and filter materials, the various benefits offer, which can be used to increase the efficiency of:

• the machine automatically detects the wire you have installed or filter and adjusts its parameters. The risk of errors is reduced to a minimum and the consumables be replaced more quickly.

• increases the availability of the machine, avoiding unnecessary interruptions when the wire or filter is used

• their inventories are reduced to a minimum

• any coil or filter data are registered and linked to the job, to ensure the full traceability of the process

This description was translated from German to English by "Bing Translator".

Die sinking spark erosion machines

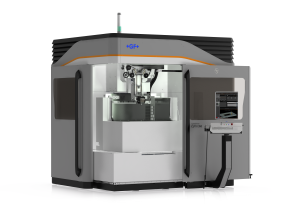

AgieCharmilles FORM E 350

|

Die sinking spark erosion machine

GF Machining Solutions GmbH

Die sinking spark erosion machines

The AgieCharmilles FORM E 350 Series gives you efficiency at the touch of a button with an intelligent, user-friendly operator interface (HMI) that incorporates technologies that streamline job set-up, increase cutting speed, improve surface finish, protect valuable parts, and ensure process reliability.

AgieCharmilles FORM E 350 are available with the optional GammaTEC technology. This technology optimizes the finishing performance for die-sinking EDM of large-surface workpieces with high-gloss optics. With the quick and easy configuration change, both standard and Gamma TEC machining operations are possible on the same machine. In particular, the Swiss generator and the many available functions of the standard configuration make the AgieCharmilles FORM E 350 a universal partner in your production chain

Translated with DeepL

AgieCharmilles FORM P 350/600/900

|

Die sinking spark erosion machine

GF Machining Solutions GmbH

Die sinking spark erosion machines

Sink erosion machines of AgieCharmilles FORM are 200 and 300 FORM with the ISPG (intelligent speed power generator) equipped, which sets new standards in terms of Oberflchenqualität, material removal and form accuracy thanks to patented technologies. The wear of the electrode is reduced in all processing operations from roughing to finishing with electrodes made of copper or graphite.

This description was translated from German to English by "Bing Translator".

AgieCharmilles FORM S 350

|

Die sinking spark erosion machine

GF Machining Solutions GmbH

Die sinking spark erosion machines

The AgieCharmilles FORM S 350 sinker spark erosion machines are fitted with an Intelligent Speed Power Generator (ISPG) which, using patented technologies, establishes new standards in surface quality, material removal and accuracy of form. Electrode wear is reduced in all machining operations, from roughing to finishing, with copper or graphite electrodes. Productivity shows an average increase of 30 percent, and can even reach 100 percent for pre-milled forms. Even in the presence of deep, narrow cavities, with poor flushing conditions, a 50 percent increase in erosion speed can be obtained with no increase in electrode wear.

AgieCharmilles FORM X 400/600

|

Die sinking spark erosion machine

GF Machining Solutions GmbH

Die sinking spark erosion machines

The EDM Jig AgieCharmilles FORM X 400/600 features a unique machine concept from Poylmerbeton and provides maximum thermal stability.

The new advanced and unique system compensates for any temperature fluctuations in non-airconditioned working environments. Here are the glass scales on the X -, Y -, Z-axis by means of thermostabiliserten dielectric oil cooled. Build a solid work table with lowerable Bowl allows easy access to the working area, even for large workpieces. An integrated modular pallet and electrode changing system offers the perfect solution for up to 12 pallets and 210 electrodes in a confined space.

This description was translated from German to English by "Bing Translator".

Start-hole electric discharge machine

AgieCharmilles DRILL 20

|

Start-hole electric discharge machine

GF Machining Solutions GmbH

Start-hole electric discharge machine

Process monitoring and optimisation is carried out via the control console. Sensors for short circuit, temperature and liquid level ensure safe operation. With an optimum price/performance ratio, the AgieCharmilles DRILL 20 high-speed drilling machine is the ideal complement to the cutting EDM system. With drilling depths of up to 200 mm and electrodes with diameters of 0.15 to 3 mm, AgieCharmilles DRILL 20 is the perfect counterbore for a comprehensive range of applications.

The AgieCharmilles DRILL 20 high-speed drilling machine has an integrated rotary spindle. The X, Y and Z axes are motorized and CNC controlled. Optimum temperature stability is ensured by the cast iron construction in C-frame design. With traverse paths of 300 x 200 x 300 mm of the X, Y and Z axes and a permissible workpiece weight of 300 kg, DRILL 20 is the ideal starting hole drilling machine for a wide range of applications. Data input at the control panel is quick and easy. Probing cycles are programmable and can be called up with a few commands.

Translated with DeepL

Laser eroding machines

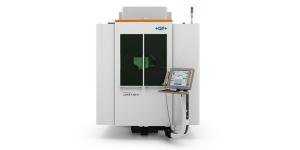

AgieCharmilles Laser P 400

|

Laser eroding machine

GF Machining Solutions GmbH

Laser eroding machines

| Abmessungen der Anlage (600 x 400 x 300 mm) |

Deliver highly accurate and repeatable results your valued customers expect. This one-ofa-kind Laser engraving, texturing and marking solution combines outstanding quality, efficiency, and femtosecond Laser technology in the smallest possible footprint. It is specifically designed for aesthetic and functional texturing of precision parts for watches and jewelry, small inserts, cutting tools and micro machined work pieces.

AgieCharmilles LASER P 600 U

|

Laser eroding machine

GF Machining Solutions GmbH

Laser eroding machines

With laser ablation, GF machining solutions provides a new product line to improve the competitive advantage of its customers. Use our new laser technology for an efficient and consistent texturing, engraving, micro structuring, marking and labeling of two - or three-dimensional shapes. The laser product line offers you unparalleled opportunities in the design of your parts. Let your creativity in three dimensions for different materials and workpiece sizes free rein. We allow independence, individuality, know-how and innovation spirit.

This description was translated from German to English by "Bing Translator".

AgieCharmilles LASER P 1200 U Dedicated

|

Laser eroding machine

GF Machining Solutions GmbH

Laser eroding machines

Promote your brand by you further bring it on your end-products in the field of view - with our personalized solution for tyre wall forming tools. Achieve a 100% repeatability in parallel operation, because our solution avoids the use of cutting tools. Bring your repeatability on the highest level.

Reach the flexibility you need! Our machine easily engraved everything from forming tools for bicycle until going to truck tires, with consistent accuracy and repeatability. Increase your productivity with the 100-Watt laser source package.

You need the way you work to change: our dedicated software module for tires, you import a .dxf file to perform the laser works simply.

This description was translated from German to English by "Bing Translator".

AgieCharmilles LASER P 600/ 1000/ 1200/ 4000 U

|

Laser eroding machine

GF Machining Solutions GmbH

Laser eroding machines

With laser ablation, GF Machining Solutions is offering a new product line to improve the competitive advantage of its customers. Use our new laser technology for efficient and repeatable texturing, engraving, microstructuring, marking and labelling of two- or three-dimensional shapes. The laser product line offers you incomparable possibilities for the design of your parts. Let your creativity run free in three dimensions for different materials and workpiece sizes. We make independence, individuality, know-how and innovative spirit possible for you.

Translated with DeepL

Laser S 1000 U/1200 U

|

Laser eroding machine

GF Machining Solutions GmbH

Laser eroding machines

The LASER S series from GF Machining Solutions sets a new standard and realizes even the most demanding product designs with maximum quality and productivity.

The laser head has two nano laser sources. The machine can thus be used to perform various applications: a high ablation rate with one laser source and additionally laser fine details with a Flexipulse laser source. The combination of a high speed 3D scanning system and a larger marking field ensures unsurpassed quality and productivity.

Translated with DeepL

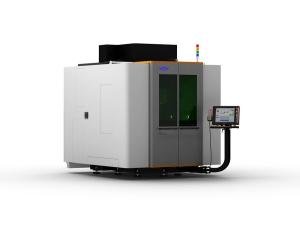

ML-5

|

Laser eroding machine

GF Machining Solutions

Laser eroding machines

Experience with the femtosecond laser technology a clean, lightning-fast micro-machining precision and high productivity. GF machining solutions offers the industry's broadest line of laser micro-processing platforms for smallest, high-precision components, to meet the increasing demand for smaller, smarter parts of the today's top products.

The ML-5 is the leading ultra-fast GL.3/5 platform and combines an exceptional part handling, a highly dynamic control and real-time position feedback, microdrilling and other micro machining to deliver in a matter of seconds. The femtosecond laser makes it possible to edit a wide variety of materials with no tool wear and no heat-affected zone. It also produces an excellent surface and edge quality.

This laser can create unique forms such as conical holes, holes that change their shape (round inlet and elliptical outlet), star pattern, and more lines that are impossible to produce on a mechanical machine.

This description was translated from German to English by "Bing Translator".