GF Machining Solutions

Products

Passion for Precision

GF Machining Solutions GmbH

High speed machining centres

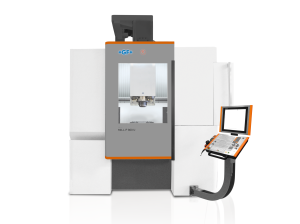

Mikron Mill P 500 U

The Micron MILL P 500 U is a 5-axis high processing center for manufacturers of precision parts, who are working in the aviation and aerospace industry and general mechanical industries, as well as pre- zisionsformenbauer from the automotive and household appliance industries.

Key messages:

• 365 days dynamic processing and flexibility thanks to the acceleration of 1.7 g, a step-TEC spindle performance of 36 kW and a swivel table capacity of up to 600 kg and a maximum diameter of 707 mm.

• 250% higher productivity with the integration of automation solutions from the back by a 12 m2 machine through.

• ±2 µm/24 hours process reliability for the precision machining of parts due to their thermal stability and the symmetrical structure of the machine.

• 98% less downtime (instead of several hours just a few minutes) by industry 4.0 GF modules such as machine and spindle collision protection (machine spindle protection MSP) and remote assistance in real time (live remote assistance, LRA).

This description was translated from German to English by "Bing Translator".

Mikron HPM 1150U

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

The MIKRON HPM 1150U is a flexible high-performance machining center, through its driving stand construction with clevis workpieces horizontally as well as vertically can edit. This allows the machining of large components with long tools. Coupled with high machining performance and reliable accuracy these machines offer a large and economic field.

The MIKRON HPM machines are designed for the universal production of high-quality parts with 3, 4 or 5 axes. State of the art motor spindles, directly driven round and rotation axes and the stable machine body provide the best conditions to produce economically and precisely with modern tools.

This description was translated from German to English by "Bing Translator".

Mikron HPM 1350U

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

The MIKRON HPM 1350U is a flexible high-performance machining center, through its driving stand construction with clevis workpieces horizontally as well as vertically can edit. This allows the machining of large components with long tools. Coupled with high machining performance and reliable accuracy these machines offer a large and economic field. Automated pallet changer with 3 x with two separate setup stations very long unmanned runtimes can be realized.

The MIKRON HPM machines are designed for the universal production of high-quality parts with 3, 4 or 5 axes. State of the art motor spindles, directly driven round and rotation axes and the stable machine body provide the best conditions to produce economically and precisely with modern tools.

This description was translated from German to English by "Bing Translator".

Mikron HSM 500

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

Basic design, high-performance spindle, control, feed drives, mechanics of the axes and the Automation are fully and completely designed for the high-speed machining to the MIKRON HSM line.

Experience has shown that the benefits of high speed milling especially for small milling cutter diameters in tool and mold making can only fully be exploited if speeds of more than 40'000 min-1 and hoheVorschubgeschwindigkeiten and best acceleration available. This fundamental requirement requires a complete customization of all machine components to the HSC technology.

This description was translated from German to English by "Bing Translator".

Mikron HSM 500 Graphite

|

High speed machining centre

GF Machining Solutions

High speed machining centres

The MIKRON HSM a high speed milling machine is designed for cutting graphite 500 graphite. Developed with our experience in high speed milling in three-axis machining in conjunction with a specialized graphite extraction. GF MS offers the optimal solution with this machine dry-cutting for graphite. The unique design allows for a clean dry machining of graphite for high accuracy, surface finish and dynamics in the process.

Graphite machining was never as attractive as it is today - and at the same time so challenge. While graphite electrodes increase the productivity in the EDM Senkerodieren (EDM) and at the same time reduce costs, the market for graphite-based glass shapes in rapid growth, with new requirements for surface quality, is Accuracy and processing speed.

The MIKRON HSM 500 graphite-gibt the ideal answer to these challenges. The proven MIKRON HSM 500, which has set a standard for speed and surface quality in the industry, was combined with a special high precision spindle by step-TEC. Additional was a black design and the integration of System 3R WPT1 + allows an improved dust extraction unit. Thus, this fast machine was a perfect solution for graphite, which leaves no marks on your work pieces or in your workshop.

The step-TEC-spindle with a maximum operating speed of 42,000 1/min ensures best surface quality and unbeatable quality of electrode. Your graphite machining production time reduced by the short acceleration and deceleration times of the spindle. The life of the spindle is extended through the oil air lubrication of the bearings.

Overcome the difficulties graphite machining with our package of graphite: the linear axes of the machine are covered and protected, noise is reduced by a dome. All linear axes and ball screws are supplied by an automatic central lubrication with grease, and a powerful vacuum sucks graphite dust effectively.

This description was translated from German to English by "Bing Translator".

Mikron HSM 700

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

Basic design, high-performance spindle, control, feed drives, mechanics of the axes and the Automation are fully and completely designed for high speed machining to the MIKRON HSM line of Micron.

Experience has shown that the benefits of high speed milling especially for small milling cutter diameters in the tool - and mold can be exploited only fully, if speeds of more than 40'000 min-1 and high Available speeds and best acceleration available. This fundamental requirement requires a complete customization of all machine components to the HSC technology.

This description was translated from German to English by "Bing Translator".

Mikron HPM 800U

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

The Mikron MILL P series offers intelligent productivity and helps tool and die manufacturers meet their challenges. Rapid market developments and forward-looking innovations require tool and die manufacturers to adapt to change. GF Machining Solutions offers these manufacturers agility for the future with the Mikron MILL P series. This five-axis milling solution is designed for high-performance milling. For best accuracy and surface finish through simultaneous machining, the machine has been equipped with water-cooled direct drives in the rotary and swivel axes. These axes can be clamped to achieve even greater rigidity during roughing. Easy access to the workpiece is provided by the large door and the short distance to the work table. Thanks to its unique concept and modularity, the machine ensures precise milling both for individual parts and in fast, high-performance series production.

Translated with DeepL

Mikron Mill S 400

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

The new development of this series Micron mill S is a milestone in the high speed milling and precision machining enters a new era. Resolves the contradiction between dynamics and precision: you can mill extremely quickly and still very accurately with feeds from 61 m per minute and part tolerances of 5 µm. And this is due to a sophisticated cooling management including cooling of the machine body independent of temperature fluctuations in the environment. You are flexible in the choice of materials: graphite aluminium and steel to carbide, inconel and titanium can cut up all materials.

The new Micron MILL S 400 series stands for high dynamic range and high precision - with reflective

Surfaces.

This description was translated from German to English by "Bing Translator".

Mikron Mill S 500

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

The new development of this series Micron mill S is a milestone in the high speed milling and precision machining enters a new era. Resolves the contradiction between dynamics and precision: you can mill extremely quickly and still very accurately with feeds from 61 m per minute and part tolerances of 5 µm. And this is due to a sophisticated cooling management including cooling of the machine body independent of temperature fluctuations in the environment. You are flexible in the choice of materials: graphite aluminium and steel to carbide, inconel and titanium can cut up all materials.

The new Micron MILL S 500 series stands for high dynamic range and high precision - with reflective surfaces.

This description was translated from German to English by "Bing Translator".

Mikron Mill S 600

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

This vertical high speed machining centers, which were developed for the tool and mold making and medium and small series production of high-quality parts, combine the know-how of gesamtetechnische as well as the comprehensive Development experience of the Swiss machine manufacturer - GF machining solutions.

The series Micron MILL S has been designed for highest precision and surface quality. The machine bed, cooling, the axis drives, motion control, tool measurement in the foreground are the necessary construction measures.

Key messages:

• linear editing at its best • very flexible for many applications • robust, very accurate • sophisticated thermal management • high precision, excellent surface quality

This description was translated from German to English by "Bing Translator".

Mikron Mill S 600 U

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

This vertical high speed machining centers designed for tool and mould construction as well as for the medium and small series production of high-quality parts, combine all the technical know-how and the comprehensive Development experience of the Swiss manufacturer GF machining solutions.

The series Micron MILL S has been designed for highest precision and surface quality. The machine bed, cooling, the axis drives, motion control, tool measurement in the foreground are the necessary construction measures.

Key messages:

• linear editing at its best • very flexible for many applications • robust, very accurate • sophisticated thermal management • high precision, excellent surface quality

This description was translated from German to English by "Bing Translator".

Mikron MILL X 400

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

Since high axis feed rates always generate a lot of heat in the drive assemblies over longer periods of time, the Mikron MILL X series has a sophisticated cooling management system. Each of the linear axes and the rotary swivel unit has its own cooling circuit. The heat is thus consistently brought out of the machine and not further distributed in the machine. This results in geometric stability, which ensures extremely high repeatability of the motion control. The Mikron MILL X 400 series sets a new milestone in both respects.

The Mikron MILL X 400 series takes precision machining into a new era. It is the precise adherence to the specified tool path, even under high feed rates, that ultimately determines the surface finish of concave and convex surfaces. Thus, for many customers, the milling texture - or rather the absence of it - on the workpiece is one of the most important performance features of a Mikron machine.

Translated with DeepL

Mikron MILL X 400 U

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

Since a lot of heat is always generated in the drive groups during high axis feeds over longer periods of time, the Mikron MILL X series has a sophisticated cooling management system. Each of the linear axes and the rotary swivel unit has its own cooling circuit. The heat is thus consistently brought out of the machine and not further distributed in the machine. This results in geometric stability, which ensures extremely high repeatability of the motion control. The Mikron MILL X 400 U series sets a "further" milestone in both points.

The Mikron MILL X series takes precision machining into a new era. It is the precise adherence to the specified tool path, even under high feed rates, that ultimately determines the surface quality of concave and convex surfaces. Thus, for many customers, the milling texture - or rather the absence of it - on the workpiece is one of the most important performance features of a Mikron machine.

Translated with DeepL

Mikron XSM 600 LP

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

The Mikron MILL X series takes precision machining into a new era. It is the precise adherence to the specified tool path, even under high feed rates, that ultimately determines the surface quality of concave and convex surfaces. Thus, for many customers, the milling texture - or rather the absence of it - on the workpiece is one of the most important performance features of a Mikron machine.

Translated with DeepL

Mikron XSM 600U LP

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

The Mikron MILL X series takes precision machining into a new era. It is the precise adherence to the specified tool path, even under high feed rates, that ultimately determines the surface quality of concave and convex surfaces. Thus, for many customers, the milling texture - or rather the absence of it - on the workpiece is one of the most important performance features of a Mikron machine.

Translated with DeepL

Mikron XSM 800 LP

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

The Mikron MILL X series takes precision machining into a new era. It is the precise adherence to the specified tool path, even under high feed rates, that ultimately determines the surface quality of concave and convex surfaces. Thus, for many customers, the milling texture - or rather the absence of it - on the workpiece is one of the most important performance features of a Mikron machine.

Translated with DeepL

Mikron HSM 200 (U) LP

|

High speed machining centre

GF Machining Solutions GmbH

High speed machining centres

With the Mikron HSM 200(U) LP we have developed a completely new machine concept. The compact and powerful 3- or 5-axis milling machine combines concentrated power in the smallest space and was designed for highest precision and surface quality.

The Mikron HSM 200(U) LP shows its strength in production environments where space and weight are critical. It is ideal for the production of high-precision components for tool and mould making, medical technology, microtechnology and the watch industry. Thus, workpieces up to 100 x 100 x 100 mm made of the most diverse materials can be processed quickly and precisely - whether they are made of metal, hard metal, non-ferrous metal, plastic, ceramics or graphite.

The machine combines concentrated power in a minimum of space.

Translated with DeepL