GF Machining Solutions

Products

Passion for Precision

GF Machining Solutions GmbH

Wire spark erosion machines

AgieCharmilles CUT 3000 S

The third generation automatic wire changer gives the AgieCharmilles CUT 3000 S wire EDM machines versatility, comfort and productivity without equal. Each user, according to his needs and circumstances, increases the profitability of his equipment thanks to the unique possibilities offered by two wire circuits.

With the new Direct Power Supply module adapted to the Intelligent Power Generator (IPG), machining times are reduced by over 30 percent.

Machining accuracy is achieved through the perfect combination of a stable mechanical concept, proven machine processes and a unique wire guiding system.

The AgieCharmilles CUT 3000 series offers the perfect balance between productivity and accuracy. Extremely accurate, flexible and able to provide complete and integrated solutions for your production tasks. Get ready for uncompromising quality results in accuracy or surface finish to achieve the highest quality parts and optimize productivity.

Translated with DeepL

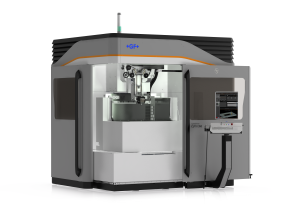

CUT X 350/550

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

Extreme accuracy:

The optimized mechanics, the new heads with 3D printing design and the AI-based thermal management form the basis for unprecedented accuracy and surface quality.

Simple:

Easy and flexible to use for both experts and beginners. Thanks to collision protection, wire annealing before threading, a new HMI and the ability to switch from open to closed guides in minutes.

Fast:

We work unbeatably fast with the Intelligent Power Generator with Direct Power Supply (IPG-DPS) and the unique Twin-Wire technology.

Translated with DeepL

AgieCharmilles CUT 1000

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

The new AgieCharmilles CUT 1000 GF machining solutions specifically designed to meet these requirements. They are characterized by unique features in perfect precision and productivity, predictability and repeatability of the processing results. This wire erosion machine sets new standards in the micro erosion.

Thanks to its exclusive machine concept the AgieCharmilles CUT satisfies the 1000 highest overlooking the positioning accuracy, as well as the moulds and detailed precision. These results through the development of an innovative machine tools design based a monobloc frame with separate X and y axes as well as static and dynamic analyses of the behaviour of the machine of tool are possible for the finite element method.

This description was translated from German to English by "Bing Translator".

AgieCharmilles CUT 1000/2000 OilTech

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

The new AgieCharmilles CUT 1000 OilTech GF machining solutions specifically designed to meet these requirements. They are characterized by unique features in perfect precision and productivity, predictability and repeatability of the processing results. This wire erosion machine sets new standards in the micro erosion.

Thanks to its exclusive machine concept the AgieCharmilles CUT meets 1000 OilTech highest overlooking the positioning accuracy, as well as the moulds and detailed precision. These results through the development of an innovative machine tools design based a monobloc frame with separate X and y axes as well as static and dynamic analyses of the behaviour of the machine of tool are possible for the finite element method.

The machining accuracy is the result of a set of technological components, such as the mechanical concept, the editing process or the wire Guide. Each component of the AgieCharmilles CUT wire erosion machines was designed in every detail with the sole aim and implements, a high accuracy over the entire service life of the machine to make sure 2000 OilTech.

Only a wire management system enables the use of all wire diameter of 0.05 to 0.30 mm. This exclusive feature of wire erosion machines AgieCharmilles CUT 2000 OilTech is no coincidence. The concept of all components involved in the wire run is based on long experience of engineers from GF machining solutions with views of high accuracy and the great flexibility of use. No additional costs incurred when a different wire diameter for producing a new tool is needed. The use of a different wire diameter requires no additional adjustment.

This description was translated from German to English by "Bing Translator".

AgieCharmilles CUT E 600

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

| 600 x 400 x 350 mm |

The AgieCharmilles CUT E 350/AgieCharmilles CUT E 600 range puts efficiency at the touch of your finger with a smart, easy-to-use human-machine interface (HMI) and onboard technologies that streamline your job setup, improve your cutting speed, improve your surface finish, protect your valuable workpieces, and ensure your process robustness.

CUT E 350

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

| 350 x 250 x 250 mm |

The AgieCharmilles CUT E 350/AgieCharmilles CUT E 600 range puts efficiency at the touch of your finger with a smart, easy-to-use human-machine interface (HMI) and onboard technologies that streamline your job setup, improve your cutting speed, improve your surface finish, protect your valuable workpieces, and ensure your process robustness.

CUT P 350/ 550/ 800/ 1250

|

Wire spark erosion machine

GF Machining Solutions GmbH

Wire spark erosion machines

In the age of the Internet of things presents GF machining solutions smart consumables with integrated RFID chips in wire and filter materials, the various benefits offer, which can be used to increase the efficiency of:

• the machine automatically detects the wire you have installed or filter and adjusts its parameters. The risk of errors is reduced to a minimum and the consumables be replaced more quickly.

• increases the availability of the machine, avoiding unnecessary interruptions when the wire or filter is used

• their inventories are reduced to a minimum

• any coil or filter data are registered and linked to the job, to ensure the full traceability of the process

This description was translated from German to English by "Bing Translator".