Hagen & Goebel Werkzeugmaschinen

Products

Machine tools

Machining centres

CNC Fräsmaschine Typ HFC-4

|

Horizontal machining centre

Hagen & Goebel Werkzeugmaschinen GmbH

Horizontal machining centres

| Workspace |

|

| 300 mm | |

| 6000 mm | |

| 300 mm | |

| 300 mm | |

| 2000 kg | |

| Travel |

|

| 300 mm | |

| 300 mm | |

| 300 mm | |

| Machine characteristics |

|

| 11500 kg | |

| Machine control |

|

| Siemens | |

The horizontal CNC – controlled milling center HFC-4 was designed to work on round or profiled workpieces in any length, quickly and easily the workpiece ends, for example. The powerful NC spindle motor in conjunction with the Siemens CNC control, type 840 Dsl ensures a stepless spindle speed range up to 9.The massively dimensioned feed axes (X,Y,Z) allow a maximum stroke of 300 mm each.

Manual or hydraulically operated workpiece clamping devices can be set up on the clamping table arranged in front of it. The mounting area has a width of 500mm and a length of 1000mm.

In contrast to the usual horizontal machining centers, the workpieces can be changed quickly and easily due to the open design of the machine. Due to the optimized design for the machining task, the machine could be designed very compactly. Due to the open design, larger workpieces play a subordinate role.

The use of CNC control and integrated standard cycles allows uncomplicated production of hole patterns and contours on workpiece ends.

The machine specification can be specially adapted to the customer's requirements. Realizable are among other things automatic tool changer, internal coolant supply, adapted speed and stroke ranges of the machining unit and much more.

This machine and its possible options have been developed by consistent implementation of many years of experience through the construction of CNC - controlled machining centers. Translated with DeepL

Manual or hydraulically operated workpiece clamping devices can be set up on the clamping table arranged in front of it. The mounting area has a width of 500mm and a length of 1000mm.

In contrast to the usual horizontal machining centers, the workpieces can be changed quickly and easily due to the open design of the machine. Due to the optimized design for the machining task, the machine could be designed very compactly. Due to the open design, larger workpieces play a subordinate role.

The use of CNC control and integrated standard cycles allows uncomplicated production of hole patterns and contours on workpiece ends.

The machine specification can be specially adapted to the customer's requirements. Realizable are among other things automatic tool changer, internal coolant supply, adapted speed and stroke ranges of the machining unit and much more.

This machine and its possible options have been developed by consistent implementation of many years of experience through the construction of CNC - controlled machining centers. Translated with DeepL

FEB 3-150

|

Horizontal machining centre

Hagen & Goebel Werkzeugmaschinen GmbH

Horizontal machining centres

| Workspace |

|

| 100 mm | |

| 6000 mm | |

| 100 mm | |

| 100 mm | |

| 2000 kg | |

| Travel |

|

| 150 mm | |

| 150 mm | |

| 150 mm | |

| Machine characteristics |

|

| 1500 kg | |

| Machine control |

|

| Siemens | |

The horizontal CNC flange and end machining machine FEB 3-150 was designed to mill, drill, deburr or thread the ends of round or profiled workpieces of any length quickly and easily. The powerful NC spindle motor in combination with the Siemens CNC control, type 840 Dsl, guarantees a stepless spindle speed range of up to 6,000 revolutions per minute. The massively dimensioned feed axes (X,Y,Z) allow a maximum stroke of 150 mm each. The clamping table in front of the machine is equipped with two manual centering clamping devices type V2 from the Hagen & Goebel product range „Busch“. The clamping range is currently 12-100mm for round material. Instead of the clamping bars, customer- or factory-specific devices can of course also be set up. In contrast to the usual horizontal machining centers, the workpieces can be changed quickly and easily thanks to the open design of the machine. Thanks to the optimized design for the machining task, the machine is very compact. Due to the open design, larger workpieces play a minor role. Through the use of CNC control and integrated standard cycles, both hole patterns and contours on workpiece ends, among others, can be produced in an uncomplicated manner. The machine specification can be specially adapted to the customer's requirements. Among other things, automatic tool changers, internal coolant supply, adapted speed and stroke ranges of the machining unit and much more can be realized. This machine and its possible options have been developed by consistent implementation of many years of experience through the construction of CNC - controlled machining centers.

Translated with DeepL

Transfer machines and machining units

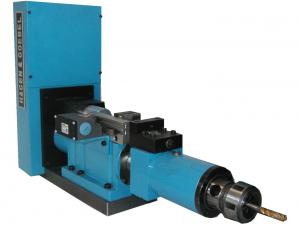

Bearbeitungseinheit bestehend aus Spindel- und Vorschubeinheit

|

Drilling unit

Hagen & Goebel Werkzeugmaschinen GmbH

Drilling units

H&G machining units are assembled from individual components.

For this purpose, spindle units of approx. 180 watts up to approx. 50 KW are used.

The feed unit arranged below has a guideway width of approx. 110mm up to 720mm as well as a maximum stroke of 4,000mm

Alternatively, hydropneumatic, hydraulic or ball screw driven systems are available for the feed drive. Translated with DeepL

For this purpose, spindle units of approx. 180 watts up to approx. 50 KW are used.

The feed unit arranged below has a guideway width of approx. 110mm up to 720mm as well as a maximum stroke of 4,000mm

Alternatively, hydropneumatic, hydraulic or ball screw driven systems are available for the feed drive. Translated with DeepL

Gewindeeinheit Typ GE 6/7

|

Threading and tapping unit

Hagen & Goebel Werkzeugmaschinen GmbH

Threading and tapping units

The threading unit type GE-6/7 was developed for the machining of small threads up to M6 in mass production. In the design, great importance was attached to low mass inertia. In conjunction with a powerful tapered vane motor capable of high changeover rates and a fast electronic control system, this results in a highly dynamic machining unit. Particularly with short thread lengths and high cycle rates (up to 140 per minute), the braking energy in the form of heat must be dissipated by a fan mounted axially on the motor. Spindle speeds of up to 5,600 rpm are possible in continuous operation without any problems.

In order to realize a feed with accurate pitch, the threading unit type GE-6/7 is equipped with a lead screw feed. The device for holding the lead screw with lead nut is arranged in the rear area for easy assembly and disassembly.

A gear ratio of i = 1:4 is installed between the lead screw and the tool, so that the tool rotates 4× faster than the lead cartridge. The advantages of this are, on the one hand, lower wear due to

lower speeds on the lead screw and, on the other hand, a 4-fold greater pitch of the lead screw. Even with very small thread pitches, the lead cartridge therefore still has a very robust thread.

The gear housing of the type GE-6/7 is filled with a smooth running oil, which lubricates the gear components as well as the lead screw.

The threaded unit type GE-6/7 in the basic version, is protected against overload by an overrun protection. Translated with DeepL

In order to realize a feed with accurate pitch, the threading unit type GE-6/7 is equipped with a lead screw feed. The device for holding the lead screw with lead nut is arranged in the rear area for easy assembly and disassembly.

A gear ratio of i = 1:4 is installed between the lead screw and the tool, so that the tool rotates 4× faster than the lead cartridge. The advantages of this are, on the one hand, lower wear due to

lower speeds on the lead screw and, on the other hand, a 4-fold greater pitch of the lead screw. Even with very small thread pitches, the lead cartridge therefore still has a very robust thread.

The gear housing of the type GE-6/7 is filled with a smooth running oil, which lubricates the gear components as well as the lead screw.

The threaded unit type GE-6/7 in the basic version, is protected against overload by an overrun protection. Translated with DeepL

Gewindeeinheiten Typ G6/50 bis G30/80

|

Threading and tapping unit

Hagen & Goebel Werkzeugmaschinen GmbH

Threading and tapping units

Hagen & Goebel thread units of the type series G6/50 to G30/80 are highly productive, automatic thread units with guide cartridge system. To protect against possible crash situations, the spindle is floating and equipped with a limit switch. The maximum permissible spindle speeds are around 1,000 rpm, depending on the size of the unit.

Translated with DeepL