HEDELIUS

Products

Machine tools

Machining centres

ACURA 65 MARATHON

|

Five-axis milling machining centre

Hedelius Maschinenfabrik GmbH

Five-axis milling machining centres

| Workspace |

|

| 370 kg | |

| Travel |

|

| 700 mm | |

| 650 mm | |

| 600 mm | |

| Machine characteristics |

|

| 7500 kg | |

| Machine control |

|

| Heidenhain, Siemens | |

The ACURA 65 MARATHON is equipped ex works with a built-in zero point clamping system for pallet automation, a side loading opening and an electrical interface for communication with the HEDELIUS pallet storage systems of the MARATHON series.

The ACURA 65 MARATHON remains accessible even with automation from the front, the view from the Rüst place to the work area is free. As standard, the machining center is equipped with a 65-cavity tool magazine. Optionally, another 25 tools are available through a MAGNUM magazine, and 264 through the connection of a standby magazine.

The ACURA 65 MARATHON remains accessible even with automation from the front, the view from the Rüst place to the work area is free. As standard, the machining center is equipped with a 65-cavity tool magazine. Optionally, another 25 tools are available through a MAGNUM magazine, and 264 through the connection of a standby magazine.

- Automating with HEDELIUS pallet handling systems of the MARATHON series .

- Loading from the left side of the machine .

- Prepared interface

- Side loading with Öopening height of approx. 900 mm

- Factory-installed Schunk Vero NSA Plus zero point clamping elements .

- Pervasive Heidenhain operating concept .

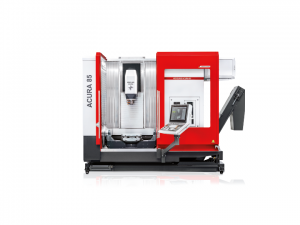

ACURA 85 MARATHON

|

Five-axis milling machining centre

Hedelius Maschinenfabrik GmbH

Five-axis milling machining centres

| Workspace |

|

| 370 kg | |

| Travel |

|

| 900 mm | |

| 850 mm | |

| 700 mm | |

| Machine characteristics |

|

| 11000 kg | |

| Machine control |

|

| Heidenhain, Siemens | |

The ACURA 85 MARATHON is equipped ex works with a built-in zero point clamping system for pallet automation, a side loading opening and an electrical interface for communication with the HEDELIUS pallet storage systems of the MARATHON series. Even with automation, the ACURA 85 MARATHON remains accessible from the front, and the view of the work area from the workstation is unobstructed. As standard, the machining center is equipped with an 80-cavity tool magazine. Optionally, a further 264 tools are available by connecting a standby magazine.

- Automating with HEDELIUS pallet handling systems of the MARATHON series .

- Loading from the left side of the machine .

- Prepared interface

- Side loading with Öopening height of approx. 900 mm

- Factory-installed Schunk Vero NSA Plus zero point clamping elements .

- Pervasive Heidenhain operating concept .

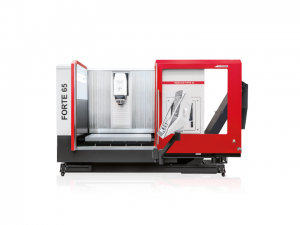

FORTE 65 SINGLE 1320

|

Vertical machining centre

Hedelius Maschinenfabrik GmbH

Vertical machining centres

| Workspace |

|

| 2000 kg | |

| Travel |

|

| 1320 mm | |

| 650 mm | |

| 600 mm | |

| Machine characteristics |

|

| 8300 kg | |

| Machine control |

|

| Heidenhain, Siemens | |

When high cutting performance and precision are required in the smallest of spaces, the FORTE 65 Single 1320 3-axis machining center is the right choice. The modern travel unit design offers high dynamics, regardless of the workpiece weight. With travels of 1320 x 650 x 600 mm, the moving-arm machining center offers a surprisingly large amount of space with small installation dimensions. Direct path measuring systems on all axes and the latest generation of drive technology ensure long-term precision.

- Large X travel of 1320 mm .

- Large Z travel of 600 mm .

- Direct measuring systems as standard .

- Fully enclosed work envelope .

- High-load, fixed machine table

- Stainless steel vertical cover for optimized chip fall

- Driving column made of high-quality machine casting .

- Highlight: Tool magazine with 65 places to be stocked during main time .

TILTENTA 10-3600

|

Five-axis milling machining centre

Hedelius Maschinenfabrik GmbH

Five-axis milling machining centres

| Workspace |

|

| 5500 kg | |

| Travel |

|

| 3600 mm | |

| 1000 mm | |

| 1000 mm | |

| Machine characteristics |

|

| 26000 kg | |

| Machine control |

|

| Heidenhain, Siemens | |

HEDELIUS has always been committed to building stable machining centers for a wide range of applications. With the TILTENTA 10, we round off the successful TILTENTA series, which has been built hundreds of times. With travels of 3600 x 1000 x 1000 (X/Y/Z) and an integrated heavy-duty rotary table with table loads of up to 1,600 kg / 2,200 kg (optional), this machine will also set standards in machine and tool manufacturing. As standard, the TILTENTA 10 is equipped with the SK50 BIG PLUS double-contact spindle system (optional: HSK A100).

Clearly üsuperior: BIG PLUS. The simultaneous taper and face contact of the tool holder in the BIG PLUS machine spindle achieves an extremely stable connection between the tool holder and the spindle. At the same time, the spindle is compatible with all SK50 receptacles.

The advantages:

Clearly üsuperior: BIG PLUS. The simultaneous taper and face contact of the tool holder in the BIG PLUS machine spindle achieves an extremely stable connection between the tool holder and the spindle. At the same time, the spindle is compatible with all SK50 receptacles.

The advantages:

- Extra-long Z-axis and Y-axis travel of 1,000 mm .

- Steplessly tilting main spindle with hydraulic clamping .

- High table load

- Optional with integrated heavy-duty rotary table .

- Highlight: tool magazine with up to 192 tools in access .

- Tool lengths up to 400 mm

TILTENTA 7-2600

|

Five-axis milling machining centre

Hedelius Maschinenfabrik GmbH

Five-axis milling machining centres

| Workspace |

|

| 2500 kg | |

| Travel |

|

| 2600 mm | |

| 750 mm | |

| 800 mm | |

| Machine characteristics |

|

| 14500 kg | |

| Machine control |

|

| Heidenhain, Siemens | |

The TILTENTA 7 opens up new areas of application in the machining of individual parts and series. Whether end machining of long workpieces or 5-sided complete machining with integrated NC rotary table – the TILTENTA 7 crossover concept solves many machining tasks in machine, tool and vehicle construction. The combination of a continuously swiveling main spindle and a long machine table with integrated NC rotary table allows mixed production of large workpieces and precise 5-axis machining in a single machine.

- Multi-purpose 5-axis machining centers from the T series .

- CNC milling machine with tilting main spindle .

- Integrated NC rotary table with high table load .

- 5-axis machining in shuttle mode possible

- Fast tool changer