HELLER Group

Products

HELLER solutions: Knowing how it's done.

Gebr. Heller Maschinenfabrik GmbH

Five-axis milling machining centres

F Series

Solid machine construction, sound process experience, a wealth of milling expertise – these are the basic ingredients for our F series 5-axis machining centres. The benefits to you are obvious: 5-axis machining with maximum output and top quality, even during continuous operation. The HELLER F-series 5-axis machining centre is the right choice for anyone wanting to perform numerous functions on one machine and produce reliably, not just today but in the future too.

5-axis machining centres F at a glance:

_universal 5-axis machining centres with the fifth axis in the tool

_flexible in use for powerful 5-sided and simultaneous 5-axis machining

_spindle units with swivel head or tilting head kinematics

_robust machine design, combined with powerful, high-torque spindle technology

_part costs optimised by reducing the number of clamping positions and machining in one set-up

_can be used for a wide range of different parts and materials

_machines with pallet changer (FP) are optimal for series production

_machines with table loading (FT) for workshop-based production and small batch sizes

_easy to automate with workpiece or pallet automation

_good range of sizes for a broad workpiece spectrum

5-axis machining centres F at a glance:

_universal 5-axis machining centres with the fifth axis in the tool

_flexible in use for powerful 5-sided and simultaneous 5-axis machining

_spindle units with swivel head or tilting head kinematics

_robust machine design, combined with powerful, high-torque spindle technology

_part costs optimised by reducing the number of clamping positions and machining in one set-up

_can be used for a wide range of different parts and materials

_machines with pallet changer (FP) are optimal for series production

_machines with table loading (FT) for workshop-based production and small batch sizes

_easy to automate with workpiece or pallet automation

_good range of sizes for a broad workpiece spectrum

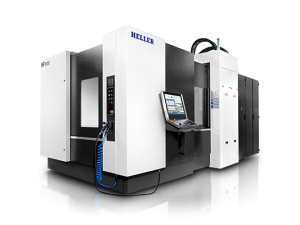

HF series

|

5-axis machining centres

Gebr. Heller Maschinenfabrik GmbH

Five-axis milling machining centres

The 5-axis machining centres from the HF series are optimally equipped to meet the exacting requirements of modern production processes. Enabling 5-sided and simultaneous 5-axis machining, they allow you to handle many different tasks on a single machine. Highly productive and flexible, with easy operation and maintenance, available with pallet changer or table loading. The second generation of the HF series provides numerous optimisations, including new spindle units with increased performance and the advantages of the HELLER zero-spindle system for minimised life cycle costs. Moreover, the option of a second drive in the Z-axis allows for even more universal application, including single-part production. In combination with the proven HELLER DNA of productivity, precision and reliability, they guarantee you increased performance, precision and flexibility for the production of your workpieces.

5-axis machining centres HF at a glance:

_horizontal 5-axis machining centres with pallet changer or table loading

_universal machining centres with 5th axis in the workpiece

_swivelling NC rotary table with counter bearing and AB kinematics with highly dynamic torque drives as standard _Mill-Turn: combination of milling and turning (option for HF 5500)

_3 equipment packages: POWER, SPEED and PRO

_short chip-to-chip times thanks to quick NC-tool changer and highest axis speed with equipment packages SPEED and PRO (option)

_5-axis machining with optimised performance: simultaneous (option) and with positioned rotary axes

_spindle units with HSK-A 63 or HSK-A 100

_gantry drive in Z-axis (option)

_horizontal spindle for optimum chip fall

_short idle times for maximum productivity

_optimum accessibility for simple operation and maintenance

_main operating unit designed as console with 24" multi-touch screen and HELLER Operation Interface

_easy to automate with workpiece or pallet automation

_machines with pallet changer optimal for series production

_machines with table loading perfect solution for workshop-based production

5-axis machining centres HF at a glance:

_horizontal 5-axis machining centres with pallet changer or table loading

_universal machining centres with 5th axis in the workpiece

_swivelling NC rotary table with counter bearing and AB kinematics with highly dynamic torque drives as standard _Mill-Turn: combination of milling and turning (option for HF 5500)

_3 equipment packages: POWER, SPEED and PRO

_short chip-to-chip times thanks to quick NC-tool changer and highest axis speed with equipment packages SPEED and PRO (option)

_5-axis machining with optimised performance: simultaneous (option) and with positioned rotary axes

_spindle units with HSK-A 63 or HSK-A 100

_gantry drive in Z-axis (option)

_horizontal spindle for optimum chip fall

_short idle times for maximum productivity

_optimum accessibility for simple operation and maintenance

_main operating unit designed as console with 24" multi-touch screen and HELLER Operation Interface

_easy to automate with workpiece or pallet automation

_machines with pallet changer optimal for series production

_machines with table loading perfect solution for workshop-based production