HELLER solutions: Knowing how it's done.

Machine tools

Machining centres

|

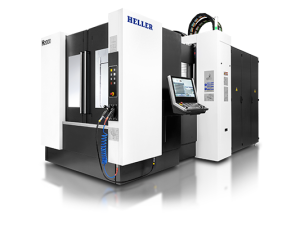

4-axis machining centres H at a glance:

_horizontal 4-axis machining centres with pallet changer as standard

_designed for high process stability and highly resilient up to limits

_top performance and short non-productive times for maximum productivity

_high availability and longevity thanks to robust, reliable technology

_24/7 series production, stand-alone or integrated in flexible manufacturing systems

_short chip-to-chip times thanks to quick tool changer and high axis dynamic

_horizontal spindle for optimum chip fall

_easy to automate with workpiece or pallet automation

_highly standardised and individually configurable

_can be used for any range of large parts and materials

_ideal solution for series production of small to medium batch sizes

_broad range of sizes suitable for almost any workpiece

_broad range of powerful machining units with specific tool shank sizes

|

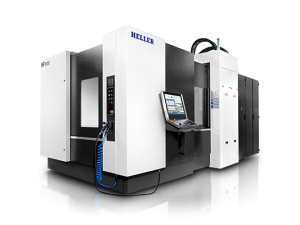

5-axis machining centres F at a glance:

_universal 5-axis machining centres with the fifth axis in the tool

_flexible in use for powerful 5-sided and simultaneous 5-axis machining

_spindle units with swivel head or tilting head kinematics

_robust machine design, combined with powerful, high-torque spindle technology

_part costs optimised by reducing the number of clamping positions and machining in one set-up

_can be used for a wide range of different parts and materials

_machines with pallet changer (FP) are optimal for series production

_machines with table loading (FT) for workshop-based production and small batch sizes

_easy to automate with workpiece or pallet automation

_good range of sizes for a broad workpiece spectrum

|

5-axis machining centres HF at a glance:

_horizontal 5-axis machining centres with pallet changer or table loading

_universal machining centres with 5th axis in the workpiece

_swivelling NC rotary table with counter bearing and AB kinematics with highly dynamic torque drives as standard _Mill-Turn: combination of milling and turning (option for HF 5500)

_3 equipment packages: POWER, SPEED and PRO

_short chip-to-chip times thanks to quick NC-tool changer and highest axis speed with equipment packages SPEED and PRO (option)

_5-axis machining with optimised performance: simultaneous (option) and with positioned rotary axes

_spindle units with HSK-A 63 or HSK-A 100

_gantry drive in Z-axis (option)

_horizontal spindle for optimum chip fall

_short idle times for maximum productivity

_optimum accessibility for simple operation and maintenance

_main operating unit designed as console with 24" multi-touch screen and HELLER Operation Interface

_easy to automate with workpiece or pallet automation

_machines with pallet changer optimal for series production

_machines with table loading perfect solution for workshop-based production

|

Powerful milling is a matter of course for HELLER machining centres. If the turning machining strategy is added, conventional milling dimensions are soon forgotten. The net result from turning, milling and HELLER's expertise in machine construction is our C-series 5-axis milling/turning machining centre – unique in terms of output, reliability and resilience.

5-axis milling/turning machining centres C at a glance:

_universal 5-axis milling/turning machining centres with the fifth axis in the tool and a DDT (Direct Drive Turning) rotary table

_powerful combination of milling and turning by one machine for optimised flexibility (Combined Processing)

_flexible in use for powerful 5-sided and simultaneous 5-axis machining, as well as turning with positioned rotary axes

_spindle units with swivel head or tilting head kinematics

_robust machine design, combined with powerful, high-torque spindle technology

_part costs optimised by reducing the number of clamping positions and complete machining in one set-up

_can be used for a wide range of different parts and materials

_machines with pallet changer (CP) are optimal for series production

_machines with table loading (CT) for workshop-based production and small batch sizes

_easy to automate with workpiece or pallet automation

Machine tools for educational purposes

|

An overview of the HELLER CNC ProfiTrainer:

_genuine machining with full machine configuration

_3-/4-/5-axis operation possible

_original industrial components in use

_reality replicated in the authentic model

_"small format" encourages trying out

_machine tolerates operating errors

_safe, low-hazard operation

_spatially unconnected, movable unit

_excellent visibility and accessibility

_equipped with the latest CNC control

_space-saving and mobile device, ideal in lecture theatres and for laboratory use

_can be operated from a 230V 16A socket

_ideal companion for the digitization topics in training and development

_can be integrated into production networks, especially in an Industrie 4.0 context

_outstanding expansion capabilities