ifm group of companies

Contact

ifm group of companies

Friedrichstr. 1 45128 Essen

Germany

Germany Route planner

Route planner

Supplier Directory P2X4A

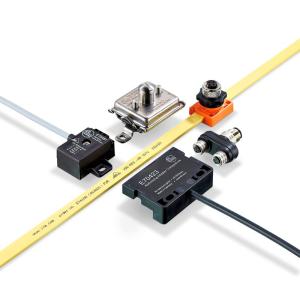

Parts and components

10

Software and Hardware

30

Controls & electronic equipment

32

Robotic and automation

1

Metrology & quality assurance

25

Safety and environment

7

Newsfeed

About us

- Founding Year

- 1969

- Number Of Employees

- 1001-10000

- Association Membership

- VDMA - German Engineering Federation

- Building Control and Management

- Fluid Power

- Working Group P2X4A

- Type of Company