Innovalia Metrology

Products

SEA Gage

|

Tool measuring and setting unit

Innovalia Metrology Munich

Measuring machines, mechanical

The range of measuring machines SEA Gage is one of the most popular models on the market due to its versatility. This machine comes in both manual and automatic, so that it can be used for measurement, digitizing, scanning or designing all kinds of parts.

Regarding measurement applications, this model is highly recommended for the measurement of geometric elements, free forms and reverse engineering. For this, the device supports contact probes (digital or analogue) and optical.

For all these reasons, SEA Gage becomes a useful measuring machine for dies, molds, models and simple parts, both manual and CNC. The air cushion support system allows for smoother and lighter movement thus achieving a substantial improvement in accuracy, stable over time.

The table, available in both granite and cast iron, allows to include holes, slots, etc., according to needs and thus the placement of parts without using tools nor support parts for positioning.

LAND Gage

|

Tool measuring and setting unit

Innovalia Metrology Munich

Measuring machines, mechanical

The range of measuring CMM arm system LAND Gage, is especially designed for measuring large volumes and therefore is one of the most popular models for manufacturers of cars and large parts.

This machine comes in both manual and automatic, so that it can be used for measurement, digitizing, scanning or designing all kinds of parts. Regarding measurement applications, this model is highly recommended for the measurement of geometric elements, free forms and reverse engineering. For this, the device supports contact probes (digital or analogue) and optical.

For all these reasons, LAND Gage becomes a very useful machine in the measurement of complete vehicles, trucks, buses and large parts, both manual and CNC. The air cushion support system allows for smoother and lighter movement thus achieving a substantial improvement in accuracy, stable over time. Its special design makes it ideal for installation at floor level, so work at height is performed more comfortably.

The no-table version allows the measurement of heavy parts without altering the machine geometry.

Spark Gage

|

Tool measuring and setting unit

Innovalia Metrology Munich

Coordinate and multiple coordinate inspection machines

This is a bridge type measuring machine, available in different sizes to suit the customer’s needs. The Spark model, as all Trimek machines, is built simple but robust, with the use of the most advanced manufacturing technologies. The machine is wholly built in black granite in its three axis, achieving a high dimensional stability and precise controlled

movements.

The measuring system of each axis is mounted on Robax (a thermally inert material) which together with the granite construction, makes the Spark Gage an accurate and fast machine even under temperature variations. The Spark is ideal for high accuracy measurements, scanning and digitising tasks. Therefore, the Spark finds its application typically in the machining, mould and stamping market.

Spark Gage Plus

|

Tool measuring and setting unit

Innovalia Metrology Munich

Coordinate and multiple coordinate inspection machines

| X 500 – 1600 | |

On the new Spark Gage Plus model, residual rotation defects are much lower than on conventional measuring machines with lateral guides. To obtain perfect measurement symmetry, the non deformable granite frame of the gantry moves on the main marble which provides the geometrical reference for the X and Y axes and below the work surface, which is also granite.

The work surface supports are placed at the corresponding edges of the machine on the floor, so that it is not possible for heavy workpieces to deform the main marble. At the top, the two granite crossbeams that provide the geometrical references for the Y-axis are perfectly embedded in the two vertical granite columns of the gantry, ensuring that there will be no deformation of the closed frame. Reader tapes stuck to the granite.

SKY Gage

|

Tool measuring and setting unit

Innovalia Metrology Munich

Coordinate and multiple coordinate inspection machines

The TRIMEK SKY range of gantry-type measuring machines is available in automatic mode for measurement, digitising or scanning of large-format parts, to a high level of precision.

With regard to measurement applications, this model is particularly recommended for measuring geometric features, free forms and inverse engineering, and so the unit can operate with optics and contact feelers (digital or analog).

The TRIMEK SKY measuring machine is the perfect machine for measurement of die-stamps, moulds, mock-ups and simple parts, in sectors where precision is of the essence such as the aeronautical industry, the wind power sector etc.

The air bag support system on all axes allows smoother and lighter movements which considerably enhance its time-stable precision.

The components are cast for greater sturdiness. The main characteristic of the TRIMEK SKY unit is that the X-axis positioning system is controlled by two reading scales (X and S) for better mechanical positioning and real-time correction of the dynamic effects of the X-axis.

The TRIMEK SKY unit can be made with or without a table attachment. Slides may be fitted to cope with heavy parts and any other customised features provided for our customers.

SKY Plus Gage

|

Tool measuring and setting unit

Innovalia Metrology Munich

Coordinate and multiple coordinate inspection machines

An extra high precision gantry type machine. Structure made entirely

of granite to guarantee precision in the face of temperature changes thus optimising the general performance of the machine. Optionally, reader rules can be mounted on quartz rules to ensure stable performance in variable temperatures.

The machine is fitted with a fourth axis unit (double motor and double reader rule on the X-axis) that ensures proper synchronism in the movement of the gantry structure (designed as a double granite beam). This means that the performance of the vertical column that gives us the Z-axis when it slides between the two beams is excellent.

In short, this is a stable, robust machine suitable for those sectors of the market that seek high precision on large volumes.

M3 portable

|

Tool measuring and setting unit

Innovalia Metrology Munich

Measuring machines, mobile

| Captura de datos y escaneo 3D de alta fidelidad. | |

| Sistema de escaneo automático, portátil y compacto. | |

| Herramienta sencilla de usar, potente y extremadamente adaptable para captura y análisis de nubes de puntos de alta calidad. | |

| OptiscanH1040L: Sensor de escaneado de alta velocidad sin contacto. | |

| M3 Compact: Software de adquisición y análisis. | |

| Control del sistema: Control de 5 Ejes, Joystick. | |

| CNC Portátil: Sistema Cartesiano CNC de 3 Ejes y Cabezal de 2 Ejes. | |

| Caja de transporte: Para la Máquina y el Control del Sistema. |

We provide solutions for different needs within the metrological software field. If you need to scan and capture point clouds your actual pieces, M3 Captureis the software you need. And if you go to manage massive point clouds and digital parts, M3 Server gives you the best solution on the market.

A breakthrough in the whole process of scanning and point cloud management is able to work in a simple and agile way in mobility. This M3 Tablet gives you a versatile and professional solution for you to work with point clouds from your tablet anywhere.

Vulkan Gage

|

Tool measuring and setting unit

Innovalia Metrology Munich

Measuring machines, mobile

| Main structure made of stabilized steel. | |

| Aluminium Y-axis unit with a pyramidal cross section arm. | |

| Linear shoes on all axes for high precision guidance. | |

| Rack and pinion drive on X-axis and ball spindle on Y- and Z-axes. | |

| Special mechanical system for arm bending control. | |

| Aluminium crosshead, supported by a guided counterweight joined through double steel cored strip. | |

| Measuring rulers and Renishaw linear optical heads on all machine axis. | |

| Continuous PHS1 head with extensions up to 750 mm. |

Machine architecture based on horizontal arm with high stiffness structure.

Tetrahedron

|

Reference standard for the acceptance and the control of coordinate measuring machine

Innovalia Metrology Munich

Reference standards for the acceptance and the control of coordinate measuring machines

| 400 mm | |

| 650 mm | |

| 900 mm | |

| 1500 mm |

Verification artifacts for machine tool based on metrological technology to offer a quick and reliable solution to the verification of the machine tool

Ball bars

|

Probing accessories 3D, probe pin, probe head, reference sphere, threaded insert

Innovalia Metrology Munich

Probing accessories 3D, probe pins, probe heads, reference spheres, threaded inserts

| 500 mm | |

| 1000 mm | |

| 1500 mm | |

| 2000 mm | |

| 2500 mm | |

| 3000 mm | |

| 4000 mm | |

| 5000 mm |

Verification artifacts for machine tool based on metrological technology to offer a quick and reliable solution to the verification of the machine tool.

M3 Arm

|

Probing accessories 3D, probe pin, probe head, reference sphere, threaded insert

Innovalia Metrology Munich

Probing accessories 3D, probe pins, probe heads, reference spheres, threaded inserts

Ideal arm for measuring any part thanks to its perfect compatibility with touch probe and optical sensor.

Features:

- One user interface for all sensors

- Increase traceability by keeping all the raw data regardless the capture technology

- Optimized software for offline programing and CAD interactions

- Automated capture of point cloud and touch points

- Titanium, aluminum and composite materials for a very light and strong structure

- Temperature sensors for automatic compensation

- Smooth counterbalance for easy use in all arm positions

- Wireless (Wi-Fi) connection between arm and computer

- 7 axes bracket mount available for different laser scanner

M3 MH Probe Kit

|

Probing accessories 3D, probe pin, probe head, reference sphere, threaded insert

Innovalia Metrology Munich

Probing accessories 3D, probe pins, probe heads, reference spheres, threaded inserts

Features and benefits

• Agile integration with all kinds of controls

• Measure, align and program intuitively

• GD&T machine tool compatible

• Tool setting

• Analysis of useful tool life

• M3 Analytics compatible (SPC)

Optical probe

• Inspection of workpieces from machining and multi-tasking machines

• Radial trigger force: 40 – 80 g

• Repeatability:

Tetracheck

|

Verification Software for CMM

Innovalia Metrology Munich

Verification Software for CMM

Tetracheck is the most effective and innovative verification system for your coordinate measurement machine. In just 5 minutes you can verify your working volume and learn about your machine errors. Now it is possible to lower your maintenance costs and improve the quality of your operations.

Our Tetracheck software package provides users with easy access to information on the current status of three-dimensional measurement machines. We provide an intuitive and easy-to-use application and user interface that is designed to enable even unqualified personnel to perform daily status checks in three basic steps:

- Measurement of 6 distances

- Automatic calculation of errors

- Report generation

Optiscan H-Class and Optiscan H-Class/HR

|

Measured data recording of test installation

Innovalia Metrology Munich

Measured data recording of test installations

| hasta 60 scans por segundo. | |

| hasta 60.000 puntos por segundo. | |

| 40 mm (10 mm con Optiscan H-Class/HR). | |

| 40 mm (15 mm con Optiscan H-Class/HR). | |

| láser Class II (no afecta a los ojos). | |

| +/- 0.010 mm (+/- 0.006 mm con Optiscan H-Class/HR). |

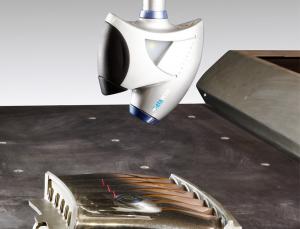

Optical sensors to obtain high accuracy 3D pointclouds of your products for reverse engineering, virtual metrology and automatic inspection.

Innovalia Metrology manufactures the OptiScan high speed 3D scanning sensors, providing the best accuracy and sensitivity on the market. With OptiScan you can obtain high accuracy 3D pointclouds of your products for reverse engineering, virtual metrology and automatic inspection.

OptiScan can work on shiny or dark surfaces without the need of spray or coating. Exclusive laser, electronics and optical technology provide the best synchronization to your mover (CMM, CNC machine, Robot, Portable arm), resulting in better accuracy and repeatability.

The OptiScan optical sensors offer a new way to inspect the quality of its products by obtaining a digital copy, and automation both as comparative against CAD dimensional measurements. Get 3D point cloud captures of the highest definition for the automotive, aeronautics, rail , wind, and consumer electronics industry.

Custom Jigs

|

Component for measuring and testing equipment, general

Innovalia Metrology Munich

Components for measuring and testing equipment, general

Innovalia Metrology control tools enable to increase repeatability and reduce time in production processes.

They also offer a significant reduction in the measurement time which allows the user to produce more parts in less time. Our checking fixtures are always delivered with:

- ENAC calibration report

- Checking fixture 3D data

- Checking fixture manufacturing drawings and material list

Advantages:

- Designed to fit any type of part

- ENAC Certification

- Increases repeatability

Fixture kits

|

Component for measuring and testing equipment, general

Innovalia Metrology Munich

Components for measuring and testing equipment, general

Innovalia Metrology?s standard fixture solutions can improve the throughput, reproducibility and accuracy of your inspection process by providing quick and repeatable fixturing set-ups for your components.

Our fixturing solutions can be assembled very quickly to increase throughput and avoid delays in inspection. They have been designed for small and medium size parts for vertical and horizontal inspection. Every component is modular and compatible with the other components to create a multifunction and reusable fixture solution.

M3 Laser Scanner

|

Scanner, 3D-Scanners, Laserscanners, Handyscan

Innovalia Metrology Munich

Scanner, 3D-Scanners, Laserscanners, Handyscan

ortable 3D scanner for fast and highly accurate measurements.

Features:

- High volumetric and hole accuracy

- Automatic surface generation

- Different scanning modes: surface and points

- Eye safe laser (Class II)

- Resolution up to 0.02mm

- Output format can be customized (e.g: .stl, .obj, .asc, .ply, .txt, etc.)

- Low weight

- USB connection

M3 Analytics

|

Software for evaluation and analysis

Innovalia Metrology Munich

Software for evaluation and analysis

Statistical analysis of metrological information and process data presented in personalized reports for full and real-time production traceability.

Advantages:

- Organise the information based on the parameters that interest you

- Analyse the production process from any device at anytime

- Create your own customized report templated to share with your clients

- Compatible with M3 Software and M3MH

MH Check

|

Software for evaluation and analysis

Innovalia Metrology Munich

Software for evaluation and analysis

MH-CHECK is an innovative system that seeks to take metrology to the next level and offer a fast, reliable solution to machine-tool checking needs. Its main characteristics are explained below.

The MH-CHECK system is made to enable the status of machine-tools to be checked quickly. Checking is performed by a self-centring head that measures a standard artefact (pattern sphere cubes, tetrahedrons and bars) and then uses calculation software to identify errors in position, perpendicularity and length in space on the machine-tool. The check takes about 10 minutes, which makes it significantly faster than other techniques.

The purpose of the MH-CHECK system is to increase the quality of the parts manufactured. It does this by running regular checks to identify machine-tool errors.

Better quality in production means greater customer satisfaction, more trust in the company, the possibility of making more complex parts, savings on rejected parts and longer spindle lifetimes, which in turn means faster production times and more efficient manufacturing.

The MH-CHECK system takes measurements in three dimensions and identifies errors in position, perpendicularity and length in space.

The results enable the machine to be calibrated by offsetting by software, making for greater accuracy in machine-tools.

Metrology software M3

|

Tool measuring and setting unit

Innovalia Metrology Munich

Software for evaluation and analysis

| M3 es compatible con diversos dispositivos de medición 3D | |

| Multisensor: Mismo flujo de trabajo para medición óptica y por contacto | |

| Conecta y mide: M3 es muy fácil de usar. Comienza a trabajar en pocos minutos | |

| Trazabilidad: Accede a tu información original en cualquier momento | |

| Potente análisis de información | |

| etc |

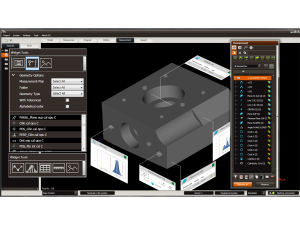

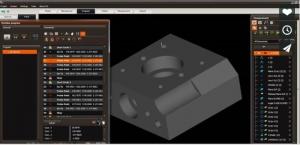

The Metrology software M3 is a High Performance Software for Capturing and Analyzing Point Clouds. M3 solves all the comprehensive process of scanning and point cloud management in a versatile, agile and powerful way.

M3MH On-machine Probing Software

|

Software supported data acquisition and control

Innovalia Metrology Munich

Software supported data acquisition and control

M3MH is the CAD/CAM measurement software for 5-axis machining centers that maximizes the performance of your machine tool by quickly verifying the machine, the optimal setup, and alignment of complex parts. The measurement of the pieces can be carried out before, during and after machining, according to the requirements of the industry and the regulations.

M3MH provides an agile connection with the control of the machine and from its intuitive interface allows you to perform the following functions:

Functions:

Axis check: verification of the rotary axes

Machine check: verification of the volume of the machine

M3MH Set up: part alignment

M3MH Measurement: pre, post, and in-process measurement