isel Germany AG

Products

Successful with cnc technology!

Software for machines

Software for CNC controls

remoteNC - universelles Steuerungsprogramm

|

Software for CNC controls

isel Germany GmbH

Software for CNC controls

Z12-334500

- runs under Windows operating systems (Windows 2000, XP, Vista, Win7 and Win8, Win10 (administrator rights required))

- is compatible with earlier program versions

- Processing of the file formats DIN 66025 (G-Code), NCP or CNC

- is available in several languages (German, English, French, Hungarian)

remoteNC is a universal control program for the output of files in the machining processes milling, drilling, gluing, engraving, applying as well as water jet cutting or laser cutting/welding.

Supported file formats are the isel-specific NCP format (ASCII file with machining data created by a CAM postprocessor), the isel-specific CNC format (ASCII files in an extended format for universal use in the field of process automation, created by ProNC) as well as the G-Code format according to DIN 66025. remoteNC is primarily used to control CNC machines for various tasks and machining operations, for this reason flexibility is a main feature of the program. A wide range of options allows easy adaptation to the respective requirements.

scope of functions

Support of digital joysticks

Control panel "File quick selection" for series production

Utility milling / multiple output with displacements

Graphical representation of the machining file with zero point and dimensions

File formats isel-NCP, DIN66025 / G-Code

Linear and circular interpolation, helical interpolation, drilling cycles

Access to digital and analog inputs and outputs

when using a CAN control: input/output "On-The-Fly" (without motion stop) for dosing applications

Message window, messages in the status line, time delay, input of variable values

Definition and use of machine positions (workpiece zero point, parking position, home position, ...)

Additional functions for file format isel-CNC (ProNC output format)

Repeat loops, counting loops,

Branchings

Arithmetic and trigonometric functions

Subroutine technology

Integral, real and string variables

Loading and saving of process variables

Access to user-specific extensions, possibility of calling user software

characteristics

compatible with earlier program versions

Processing of the file formats DIN66025(G-Code), NCP or CNC

immediate processing without conversion, translation or transformation of the file

integrated text editor with numerous functions for quick corrections to the existing NC program

Use of up to 6 interpolating axes (Cartesian coordinate system and 3 auxiliary axes)

Look-ahead path processing with CAN control

Management of a milling spindle

2 I/O units can be used (max. 64 inputs, 64 outputs)

Translated with DeepL

Programming systems for CNC machines

PAL-PC - Prozessautomatisierungssoftware für Windows

|

Programming systems for CNC machines

isel Germany GmbH

Programming systems for CNC machines

Z11-331810

PAL-PC program development environment for CNC stepper motor controllers

General

PAL-PC enables the fast, simple and cost-effective realisation of automation projects such as handling systems, automatic drilling machines, cycle devices, measuring and testing systems, automatic machines for individual and series processing and much more

- PAL-PC is a modern program development environment for CNC stepper motor controllers and CNC machines.

- PAL-PC uses the memory operation (CNC mode) of the target controller. PAL-PC is used to create automation solutions in which the controller operates in stand-alone mode, i.e. independently of a control computer.

- PAL-PC runs under the operating systems Windows 2000, XP, Vista and Win7.

scope of functions

Position commands for relative and absolute positioning

Execute movement until event occurs at an input

Teach-in programming (linear)

Linear 2D interpolation, switchable to 3D interpolation

Circular interpolation

Evaluation of input signals for process control

Loops for repeating statement blocks

Unconditional and conditional branching

Evaluation of the program selection unit

Output of messages on a display

Sending and receiving synchronization characters

Additional tools for automated processing of typical tasks

Translated with DeepL

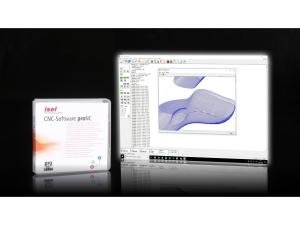

proNC Software

|

Programming systems for CNC machines

isel Germany GmbH

Programming systems for CNC machines

Z11-333500

The universal CNC software

- runs under the operating systems Windows 7 / 10 (administrator rights required) ProNC and controller of isel ProNC applications can be created according to isel-PAL or DIN66025

- is available for current control systems

- ProNC is perfectly suited for automation solutions!

Features

Programming according to DIN66025 (G-codes) or isel-PAL

compatible with earlier program versions (ProDIN, proPAL)

integrated text editor with numerous functions for fast and efficient editing of the source code

Import of geometry data (NCP, e.g. from isy-CAD/CAM)

Use of up to 6 interpolating axes and up to 6 handling axes (with CAN control)

Look-ahead path machining with CAN control up to 4 spindle motors can be used up to 4 I/O units can be used

(max. 64 inputs, 64 outputs)

Signalling inputs and outputs for process synchronisation

Teach-in with joystick, keyboard and mouse

Offline programming with simulation modules

step-by-step editing, breakpoints and system monitoring for commissioning

individually expandable with software libraries

Control panels for motion control, input/output, spindles and tool change with buttons

Control panel for max. 6 handling axes independent of the interpolating axes

available in German and English

Translated with DeepL