LANG Technik

Products

simple. gripping. future.

Machine vices

5-Achs-Spanner

|

Machine vice

LANG Technik GmbH

Machine vices

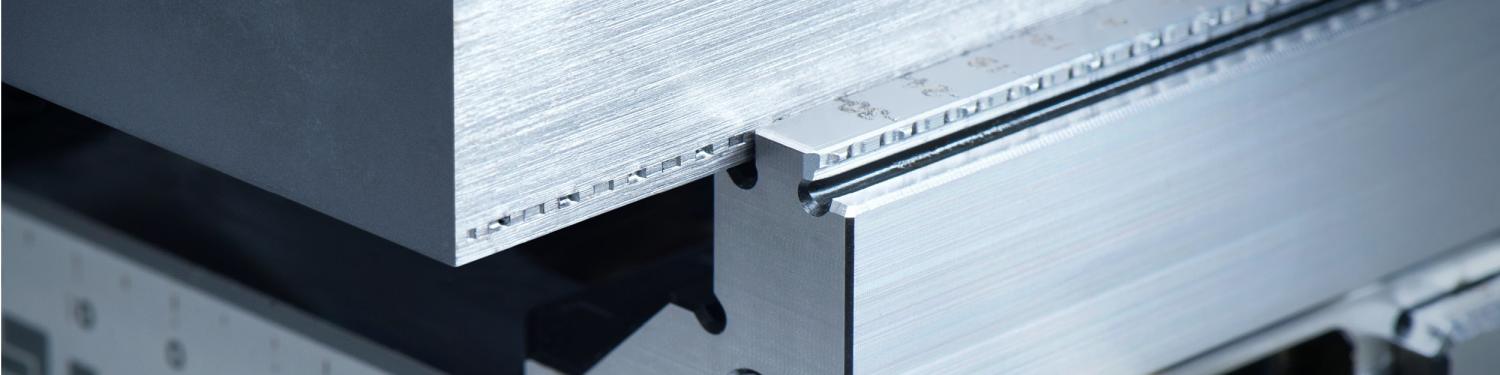

The 5-axis clamp is today's benchmark in 5-sided machining of blanks.

The compact machine vice convinces with highest holding forces and an ideal accessibility.

Thanks to the positive clamping principle with its toothed clamping jaws, it holds the workpiece gently and securely at the same time - with a clamping margin of just 3 mm.

A low clamping pressure prevents deformation when unclamping the machined blank.

By simply turning the clamping jaws, which are milled from solid material, the 5-axis clamp enables a clamping range that is almost identical to the base body length.

The centering clamp does not require any additional workpiece stops, which means that it is easily accessible from all sides and offers hardly any interfering contours.

Thanks to the defined positioning of the workpiece blank in the serration, workpieces can be clamped and unclamped with repeat accuracy - for reworking, for example.

Equipped with an integrated zero point fixture, it is set up and dismantled in its own zero point clamping system with a repeat accuracy of < 0.005 mm.

In addition to the standard toothed clamping jaws, other jaw types are compatible on the robust base body made of case-hardened steel - such as top jaws for clamping profile and molded parts, or grip jaws for blank clamping of cylindrical components.

The 5-axis clamp is available in jaw widths of 46, 77 and 125 mm, with a maximum clamping range of 355 mm.

Translated with DeepL

Platten- und Großbauteilspannung

|

Machine vice

LANG Technik GmbH

Machine vices

Workpiece clamping in new dimensions

The Makro-Grip® Ultra product group offers maximum modularity and an impressive variety of application possibilities. Thanks to the expandability of the individual clamping modules, components from 40 - 810 mm in length can be securely clamped with Makro-Grip® Ultra. In this size range, LANG clamping technology is advancing into new dimensions and now also offers a solution for mold making and the clamping of plates and large components.

The clamping system consists of several basic bodies that can be combined with each other and are available in different system heights. In addition, Makro-Grip® Ultra offers the possibility of clamping any component shape - whether cubic, round or asymmetric - thanks to various clamping jaw types. In addition, the user can decide whether to clamp a single or several workpieces at the same time.

With its numerous configuration options, the modular system is suitable for virtually any clamping situation. With a longer threaded spindle, the clamping system can be significantly extended (e.g. to 1,500 mm clamping travel). Likewise, further clamping modules can be added quite easily in the y-direction. With a repeatability of < 0.005 mm, Makro-Grip® Ultra can be set up and dismantled in the zero point clamping system within a few moments, but can also be permanently attached to the machine table via base plates.

Translated with DeepL