Lerinc

Products

Palletising of workpieces and tools

Pal-Tec FPA

|

Palletising of workpieces and tools

Lerinc Werkzeugmaschinen & Automation GmbH

Palletising of workpieces and tools

INCREASE IN PRODUCTIVITY

The optimization of your production processes is the declared goal of the specialists at Pal-Tec Automation GmbH.

This is made possible by innovative automation solutions, ranging from low-cost production cells to interlinked systems with several processing centres combined with single or multilevel rack systems.

EXAMPLE OF PRACTICE

Realisation of a flexible pallet automation for a horizontal machining centre, suitable for mixed operation with Euro and machine pallets in the following specification:

1 machining centre

45 Shelf storage (2-row, 3 levels)

1 loading station for machine pallets

2 loading stations for Euro pallets

Space requirement no more than 12 x 15 meters

Translated with DeepL

PAL-TEC Palettenspeicher

|

Palletising of workpieces and tools

Lerinc Werkzeugmaschinen & Automation GmbH

Palletising of workpieces and tools

MAXIMUM ECONOMIC EFFICIENCY

Flexible automation concepts increase productivity. The automation solutions from PAL-TEC are particularly characterised by user-friendliness and speed.

Highest availability and flexible use due to modular design are the guarantees for a successful automation of horizontal machining centers of all well-known manufacturers. The spectrum ranges from flexible production cells to interlinked systems.

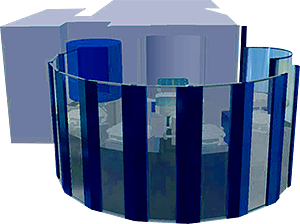

VPP MEMORY

Vertical pallet storage systems (VPP) were designed for low-manpower production with an integrated machining centre.

Pallet sizes from 400 to 800 mm

Workpiece oscillating circuits/heights from 630/750 mm to 1,300/1,300 mm

Transfer weights from 650 to 3,000 kg

1, 2 or 3 levels

Modular design consisting of:

Storage elements

Storage and retrieval machine

Electrics

Preparation for control by machine tool

Translated with DeepL