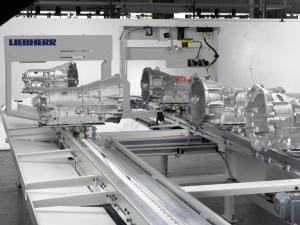

Liebherr-Verzahntechnik

Products

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

Timer chain conveyors (TKB)

| 50 kg | |

| cyclic | |

| Yes | |

| cubic components / rotationally symmetric components | |

| any / max. 12 m per drive | |

| 1,800 kg | |

| 150 kg | |

| Three-phase current geared motor | |

| 5 m/min | |

| 1-track | |

Liebherr's indexing chain conveyors provide an optimal and cost-effective solution to various transport tasks such as line loading, intermediate storage or the discharge of NIO parts.

KKB H

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 150 kg | |

| accumulative | |

| Yes | |

| cubic components | |

| any / max. 10 m per drive | |

| Three-phase current geared motor | |

| 6 m/min | |

| 1-track |

By holding the workpieces on a pallet, any geometric shapes can be transported.

KKB L

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 30 kg | |

| accumulative | |

| Yes | |

| rotationally symmetric components | |

| any / max. 10 m per drive | |

| 300 kg | |

| Three-phase current geared motor | |

| 6 m/min | |

| 1-track |

By holding the workpieces on a pallet, any geometric shapes can be transported.

KKB M

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 50 kg | |

| accumulative | |

| Yes | |

| cubic components / rotationally symmetric components | |

| Three-phase current geared motor | |

| 6 m/min | |

| 1-track |

By holding the workpieces on a pallet, any geometric shapes can be transported.

Drag frame belt (SRB 35)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 35 kg | |

| cyclic | |

| Carrier frame | |

| rotationally symmetric components | |

| Servomotor | |

| 10 m/min | |

| 1-track |

The transport takes place either directly on the conveyor or indirectly via workpiece carriers. Due to the prism-shaped holders, change parts are not normally required.

Drag frame belt (SRB 70)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 70 kg | |

| cyclic | |

| Carrier frame | |

| rotationally symmetric components | |

| Servomotor | |

| 10 m/min | |

| 1-track |

The transport takes place either directly on the conveyor or indirectly via workpiece carriers. Due to the prism-shaped holders, change parts are not normally required.

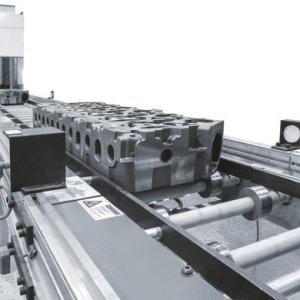

Friction roller conveyor (FRB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 80 kg | |

| akkummulierend | |

| möglich | |

| kubische Teile | |

| beliebig / max. 6 m je Antrieb | |

| 110 mm | |

| 140 mm | |

| 40 mm | |

| 80 mm | |

| 450 mm, 550 mm | |

| 2.700 kg | |

| 450 kg | |

| Drehstromgetriebemotor | |

| 6 m/min | |

| 9 m/min | |

| 1-spurig |

Friction roller belts can be used to transport workpieces directly or on pallets. Due to the stringing effect, they are cycle-independent.

Translated with DeepL

Plastic chain conveyors (KKB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

The plastic chain conveyors are designed to transport any number of unevenly-shaped workpieces without them touching each other. The workpieces are transported on pallets. Modular corner pieces mean that any type of conveyor shape is possible. Parallel machines are connected using satellite units.

Technical data :

Workpiece weight (Standard) [kg]:max. 20

Workpiece weight (heavy load) [kg]: max. 180

Conveyor length [m]: max. 10 je Antrieb

Transport capacity per drive [kg]: 300

Propulsion: Three-phase gear motor

Number of drives: max. 4

Transport speed [m/min]: 6/12

Workpiece diameter (standard) [mm]: max. 400, special sizes on request

Additional equipment: Spin apparatus, suction unit, identification equipment, stacker, tilt/turn device, adjustable workpiece holder, roller supports for heavy-duty version, tilt protection for upright parts

Pallet accumulating conveyors (PSB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 120 kg | |

| accumulative | |

| Yes | |

| cubic components / rotationally symmetric components | |

| any / max. 12 m per drive | |

| 1,300 | |

| 260 kg | |

| Three-phase current geared motor kg | |

| 6 m/min | |

| 1-track | |

Pallet accumulating conveyors are designed for the pallet transport of workpieces within the production area. The pallet return is automatic without lifting and lowering stations. Based on their accumulating ability, they are indexing Independent.

Technical data:

Workpiece weight [kg]: max. 80

Conveyor length [m]: max. 20

Transport capacity [kg]: 1,000

Propulsion: Three-phase gear motor

Transport speed [m/min]: 6

Hinged chain conveyors (SKB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 10 kg | |

| accumulative | |

| No | |

| cubic components / rotationally symmetric components | |

| any / max. 12 m per drive | |

| 300 kg | |

| Three-phase current geared motor | |

| 6 m/min | |

| 6 m/min | |

The hinged chain conveyors are designed for direct transport of workpieces with an even surface, that may touch during transport. For workpieces which are heavy or do not have an even surface, a multiple lane design is possible.

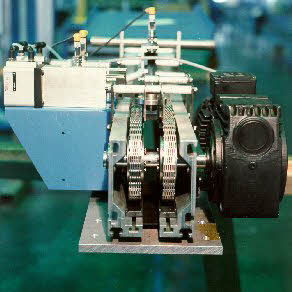

Drag frame conveyors (SRB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

The drag frame belts are designed for disc-shaped parts such as gear wheels, hubs and rings. The workpieces are dragged by a frame connected to a chain. The parts are transported either directly on the transport belt or indirectly using workpiece supports. Prism-shaped holders mean that exchangeable parts are not normally needed. At the transfer point for loading a machine, the workpiece is positioned using a servo system centrally under the loading/unloading point.

Technical data:

Workpiece weight [kg]: max. 70

Conveyor length [m]: max. 20

Transport capacity [kg]: 1,200

Propulsion: Servo Motor

Transport Speed [m/min]: 9

Workpiece Diameter (standarad) [mm]: 30 - 380

Accumulating conveyors (SFB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 50 kg | |

| accumulative | |

| Possible | |

| cubic components | |

| any / max. 14 m per drive | |

| 2,700 kg | |

| 450 kg | |

| Three-phase current geared motor | |

| 6 m/min | |

| 9 m/min | |

| 1-track |

The accumulating conveyors are designed for the direct and indirect transport of workpieces onto pallets. Because of indivdually connected conveyor sections, the transport length can be extended any time if desired. The pallet return is performed by lifting and lowering stations. Because of their accumulating ability, they are indexing independent.

Toothed chain conveyors (ZKB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 10 kg | |

| accumulative | |

| No | |

| cubic components / rotationally symmetric components | |

| any / max. 12 m per drive | |

| 300 kg | |

| Three-phase current geared motor | |

| 6 m/min | |

| 1-track | |

The toothed chain conveyors are designed for direct transport of workpieces with an uneven surface (e.g. pins or collars), that may touch during transport. Based on their accumulating ability, they are indexing independent.

Technical data:

Workpiece weight [kg]: max. 10

Conveyor length [m]: max. 14

Transport capacity [kg]: 300

Propulsion: Three-phase motor with plug-in gears

Transport speed [m/min]: 6

Belt design: 2 tracks

Workpiece diameter (standard) [mm]: max. 300, special sizes on request

Additional equipment: Spin apparatus, suction unit, identification equipment, manual central workpiece guide adjustment