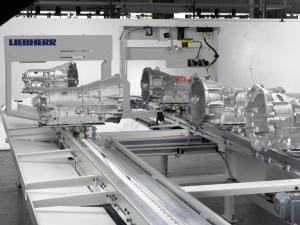

Liebherr-Verzahntechnik

Products

Robotic and automation

Workpiece and tool handling

LPC 3400

|

Palletising of workpieces and tools

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising of workpieces and tools

| Three-Unit-Cell | |

| 600 x 400 mm | |

| Bins / Plastic pallets / Workpiece carrier | |

| 1,200 mm | |

| Servomotor | |

| integrated | |

| Robots |

Automation with a uniform basic system

The Liebherr palletizing cell can be used to implement a wide variety of production concepts. A uniform basic system can be used to automate production islands with individual machine loading, cell systems with raw and finished part storage, and even decoupling modules in line systems.

Translated with DeepL

LPC 3600

|

Palletising of workpieces and tools

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising of workpieces and tools

| Three-Unit-Cell | |

| 800 x 600 mm | |

| Bins / Plastic pallets / Workpiece carrier | |

| 1,350 mm | |

| Servomotor | |

| integrated | |

| Roboter |

Automation with a uniform basic system

The Liebherr palletizing cell can be used to implement a wide variety of production concepts. A uniform basic system can be used to automate production islands with individual machine loading, cell systems with raw and finished part storage, and even decoupling modules in line systems.

Translated with DeepL

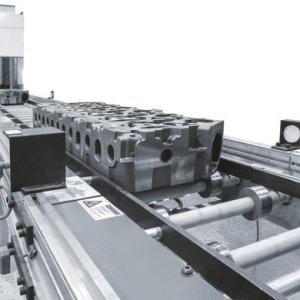

Automation for storage and transportation

KKB H

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 150 kg | |

| accumulative | |

| Yes | |

| cubic components | |

| any / max. 10 m per drive | |

| Three-phase current geared motor | |

| 6 m/min | |

| 1-track |

By holding the workpieces on a pallet, any geometric shapes can be transported.

KKB L

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 30 kg | |

| accumulative | |

| Yes | |

| rotationally symmetric components | |

| any / max. 10 m per drive | |

| 300 kg | |

| Three-phase current geared motor | |

| 6 m/min | |

| 1-track |

By holding the workpieces on a pallet, any geometric shapes can be transported.

KKB M

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 50 kg | |

| accumulative | |

| Yes | |

| cubic components / rotationally symmetric components | |

| Three-phase current geared motor | |

| 6 m/min | |

| 1-track |

By holding the workpieces on a pallet, any geometric shapes can be transported.

Drag frame belt (SRB 35)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 35 kg | |

| cyclic | |

| Carrier frame | |

| rotationally symmetric components | |

| Servomotor | |

| 10 m/min | |

| 1-track |

The transport takes place either directly on the conveyor or indirectly via workpiece carriers. Due to the prism-shaped holders, change parts are not normally required.

Drag frame belt (SRB 70)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 70 kg | |

| cyclic | |

| Carrier frame | |

| rotationally symmetric components | |

| Servomotor | |

| 10 m/min | |

| 1-track |

The transport takes place either directly on the conveyor or indirectly via workpiece carriers. Due to the prism-shaped holders, change parts are not normally required.

Friction roller conveyor (FRB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 80 kg | |

| akkummulierend | |

| möglich | |

| kubische Teile | |

| beliebig / max. 6 m je Antrieb | |

| 110 mm | |

| 140 mm | |

| 40 mm | |

| 80 mm | |

| 450 mm, 550 mm | |

| 2.700 kg | |

| 450 kg | |

| Drehstromgetriebemotor | |

| 6 m/min | |

| 9 m/min | |

| 1-spurig |

Friction roller belts can be used to transport workpieces directly or on pallets. Due to the stringing effect, they are cycle-independent.

Translated with DeepL

Plastic chain conveyors (KKB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

The plastic chain conveyors are designed to transport any number of unevenly-shaped workpieces without them touching each other. The workpieces are transported on pallets. Modular corner pieces mean that any type of conveyor shape is possible. Parallel machines are connected using satellite units.

Technical data :

Workpiece weight (Standard) [kg]:max. 20

Workpiece weight (heavy load) [kg]: max. 180

Conveyor length [m]: max. 10 je Antrieb

Transport capacity per drive [kg]: 300

Propulsion: Three-phase gear motor

Number of drives: max. 4

Transport speed [m/min]: 6/12

Workpiece diameter (standard) [mm]: max. 400, special sizes on request

Additional equipment: Spin apparatus, suction unit, identification equipment, stacker, tilt/turn device, adjustable workpiece holder, roller supports for heavy-duty version, tilt protection for upright parts

Pallet accumulating conveyors (PSB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 120 kg | |

| accumulative | |

| Yes | |

| cubic components / rotationally symmetric components | |

| any / max. 12 m per drive | |

| 1,300 | |

| 260 kg | |

| Three-phase current geared motor kg | |

| 6 m/min | |

| 1-track | |

Pallet accumulating conveyors are designed for the pallet transport of workpieces within the production area. The pallet return is automatic without lifting and lowering stations. Based on their accumulating ability, they are indexing Independent.

Technical data:

Workpiece weight [kg]: max. 80

Conveyor length [m]: max. 20

Transport capacity [kg]: 1,000

Propulsion: Three-phase gear motor

Transport speed [m/min]: 6

Hinged chain conveyors (SKB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 10 kg | |

| accumulative | |

| No | |

| cubic components / rotationally symmetric components | |

| any / max. 12 m per drive | |

| 300 kg | |

| Three-phase current geared motor | |

| 6 m/min | |

| 6 m/min | |

The hinged chain conveyors are designed for direct transport of workpieces with an even surface, that may touch during transport. For workpieces which are heavy or do not have an even surface, a multiple lane design is possible.

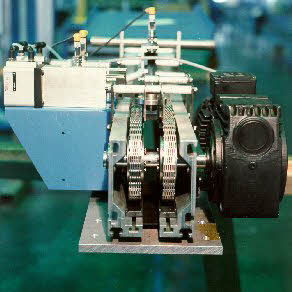

Drag frame conveyors (SRB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

The drag frame belts are designed for disc-shaped parts such as gear wheels, hubs and rings. The workpieces are dragged by a frame connected to a chain. The parts are transported either directly on the transport belt or indirectly using workpiece supports. Prism-shaped holders mean that exchangeable parts are not normally needed. At the transfer point for loading a machine, the workpiece is positioned using a servo system centrally under the loading/unloading point.

Technical data:

Workpiece weight [kg]: max. 70

Conveyor length [m]: max. 20

Transport capacity [kg]: 1,200

Propulsion: Servo Motor

Transport Speed [m/min]: 9

Workpiece Diameter (standarad) [mm]: 30 - 380

Accumulating conveyors (SFB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 50 kg | |

| accumulative | |

| Possible | |

| cubic components | |

| any / max. 14 m per drive | |

| 2,700 kg | |

| 450 kg | |

| Three-phase current geared motor | |

| 6 m/min | |

| 9 m/min | |

| 1-track |

The accumulating conveyors are designed for the direct and indirect transport of workpieces onto pallets. Because of indivdually connected conveyor sections, the transport length can be extended any time if desired. The pallet return is performed by lifting and lowering stations. Because of their accumulating ability, they are indexing independent.

Timer chain conveyors (TKB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 50 kg | |

| cyclic | |

| Yes | |

| cubic components / rotationally symmetric components | |

| any / max. 12 m per drive | |

| 1,800 kg | |

| 150 kg | |

| Three-phase current geared motor | |

| 5 m/min | |

| 1-track | |

Liebherr's indexing chain conveyors provide an optimal and cost-effective solution to various transport tasks such as line loading, intermediate storage or the discharge of NIO parts.

Toothed chain conveyors (ZKB)

|

Conveying equipment and systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Conveying equipment and systems

| 10 kg | |

| accumulative | |

| No | |

| cubic components / rotationally symmetric components | |

| any / max. 12 m per drive | |

| 300 kg | |

| Three-phase current geared motor | |

| 6 m/min | |

| 1-track | |

The toothed chain conveyors are designed for direct transport of workpieces with an uneven surface (e.g. pins or collars), that may touch during transport. Based on their accumulating ability, they are indexing independent.

Technical data:

Workpiece weight [kg]: max. 10

Conveyor length [m]: max. 14

Transport capacity [kg]: 300

Propulsion: Three-phase motor with plug-in gears

Transport speed [m/min]: 6

Belt design: 2 tracks

Workpiece diameter (standard) [mm]: max. 300, special sizes on request

Additional equipment: Spin apparatus, suction unit, identification equipment, manual central workpiece guide adjustment

PHS 800 Allround

|

Palletising systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising systems

| 800 kg | |

| 2 x 600 kg | |

| Ø600 / Ø900 | |

| 400 x 400 / 630 x 630 | |

| 2 to 3 | |

| 1,200 mm (2 shelf levels) |

Liebherr automation for flexible manufacturing!

In the PHS Allround, Liebherr offers a space-saving and flexible manufacturing system, even for small batch sizes. It automatically equips machine tools with machine pallets. The pallet handling system increases the machine runtime to up to 90 % and reduces unit costs by up to 40 %. Using the modular system, our customers can configure their system individually while still enjoying the advantages of a standard product: low price, fast delivery time, excellent replacement part availability.

PHS 1500 Allround

|

Palletising systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising systems

| 1500 kg | |

| 2 x 1,200 kg | |

| Ø900 / Ø1,400 | |

| 630 x 630 / 800 x 800 | |

| 2 to 3 | |

| 1,200 mm (2 shelf levels) |

Liebherr automation for flexible manufacturing!

In the PHS Allround, Liebherr offers a space-saving and flexible manufacturing system, even for small batch sizes. It automatically equips machine tools with machine pallets. The pallet handling system increases the machine runtime to up to 90 % and reduces unit costs by up to 40 %. Using the modular system, our customers can configure their system individually while still enjoying the advantages of a standard product: low price, fast delivery time, excellent replacement part availability.

PHS 3000 Allround

|

Palletising systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising systems

| 3,000 kg | |

| Not available | |

| Ø1,400 / Ø1,700 | |

| 800 x 800 / 1,000 x 1,000 | |

| 2 to 3 | |

| 1,600 mm (2 shelf levels) |

Liebherr automation for flexible manufacturing!

In the PHS Allround, Liebherr offers a space-saving and flexible manufacturing system, even for small batch sizes. It automatically equips machine tools with machine pallets. The pallet handling system increases the machine runtime to up to 90 % and reduces unit costs by up to 40 %. Using the modular system, our customers can configure their system individually while still enjoying the advantages of a standard product: low price, fast delivery time, excellent replacement part availability.

Systems for handling pallets

|

Palletising systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising systems

Liebherr-Verzahntechnik GmbH offers an extensive range of automation systems that support modern high-efficiency production. They not only assist in reducing the production costs, but also permit short-term and flexible responses to changes in the demands of the market. In the field of pallet handling systems, Liebherr complements the established linear PHS with the new RLS rotation loading system.

Both pallet handling systems are primarily used for the automatic loading of machining centres. The PHS is available in four sizes to transport loads ranging from 100 to 6,500 kg. The RLS is available in two sizes and is designed to transport loads ranging from 500 to 1,500 kg. Each of the automation devices presented here are part of a modular system that can be individually adapted to the particular application. The number of connected machines as well as equipment and storage slots remains variable.

PHS 750

|

Palletising systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising systems

| 1,200 kg | |

| 1000 x 1000 mm | |

| max. 630 x 630 mm | |

| 180 m/min | |

| 1.0 m/s² | |

| 90 m/min | |

| 1.0 m/s² | |

| 48 m/min | |

| 96 m/min | |

| 0.5 m/s² | |

| 2.00 m/s² | |

| max. 630 x 630 mm | |

| Siemens | |

| SOFLEX PCS |

The flexible automation for machining centers

The modular concept allows unlimited flexibility in the implementation of customer requirements. Machine tools from all manufacturers can be integrated into the system. If required, the system can be expanded with a tool handling system.

PHS 1500

|

Palletising systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising systems

| 2.500 kg | |

| 2000 x 1400 mm | |

| max. 1000 x 800 mm | |

| 180 m/min | |

| 1,0 m/s² | |

| 30 m/min | |

| 1,0 m/s² | |

| 48 m/min | |

| 96 m/min | |

| 0,5 m/s² | |

| 2,00 m/s² | |

| max. 800 x 1.200 mm | |

| Siemens | |

| SOFLEX PCS |

The flexible automation for machining centers

The modular concept allows unlimited flexibility in the implementation of customer requirements. Machine tools from all manufacturers can be integrated into the system. If required, the system can be expanded with a tool handling system.

PHS 3500

|

Palletising systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising systems

| 6.500 kg | |

| 3000 x 2500 mm | |

| max. 1600 x 1250 mm | |

| 120 m/min | |

| 1,0 m/s² | |

| 30 m/min | |

| 0,5 m/s² | |

| 48 m/min | |

| 96 m/min | |

| 0,5 m/s² | |

| 2,00 m/s² | |

| Siemens | |

| SOFLEX PCS |

The flexible automation for machining centers

The modular concept allows unlimited flexibility in the implementation of customer requirements. Machine tools from all manufacturers can be integrated into the system. If required, the system can be expanded with a tool handling system.

PHS 10000

|

Palletising systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising systems

| 13.000 kg | |

| 4000 x 2500 mm | |

| max. 2000 x 1600 mm | |

| 90 m/min | |

| 0,5 m/s² | |

| 13 m/min | |

| 0,2 m/s² | |

| 30 m/min | |

| 120 m/min | |

| 0,2 m/s² | |

| 0,40 m/s² | |

| Siemens | |

| SOFLEX PCS |

The flexible automation for machining centers

The modular concept allows unlimited flexibility in the implementation of customer requirements. Machine tools from all manufacturers can be integrated into the system. If required, the system can be expanded with a tool handling system.

Pallet handling system

|

Palletising systems

Liebherr-Verzahntechnik GmbH Verzahntechnik und Automationssysteme

Palletising systems

Liebherr-Verzahntechnik GmbH offers an extensive range of automation systems that support modern high-efficiency production. They not only assist in reducing the production costs, but also permit short-term and flexible responses to changes in the demands of the market. In the field of pallet handling systems, Liebherr complements the established linear PHS with the new RLS rotation loading system.

The RLS is characterized by its high storage density per installation area as well as by its flexibility and user-friendliness. The great advantage of the PHS is the unique optional front access to the machine. Front access makes unrestricted manual as well as automatic operation possible.

Loading ...