LTI Motion

Products

Controls & electronic equipment

Other electric and electronic components and assemblies

Magnetic bearing motors / generators

|

Electric motor

LTI Motion GmbH

Electric motors

Complete drive solutions for high-speed applications

• Optimal solution for blower and turbine applications

• Can be used as magnetic bearing motor or generator

• Completely maintenance-free

• Power: up to 300 kW

• Speed: up to 70,000 min-1 (depending on the pressure Ratio, performance and the medium)

• Scope of supply: without impeller

• Built-in or separate magnetic bearing electronics for simple and low cost installation

• Integrated water cooling

Motor parts

|

Electric motor

LTI Motion GmbH

Electric motors

Customized high-speed and motor elements

• Power range of up to 300 kW

• Speeds: up to more than 100,000 min-1

• Laminations up to 300 mm (outer diameter)

Our motor parts are characterized by:

• wide speed ranges

• very compact design

• low losses

• air or water cooling

• rotor and stator designs specially adapted to the application

• full potting possible for optimal thermal coupling

For example, application in:

• Machine tool spindles

• Liquid pumps

• Turbine fans

• Turbo generators

• Compressors and expanders

• Vacuum pumps …

Servo motors

|

Electric motor

LTI Motion GmbH

Electric motors

Motor competence for mechanical Engineering

• Synchronous servo motors:

0.1 Nm - 1,344 Nm

• Asynchronous servo motors:

33 Nm - 3,024 Nm

• Gear direct mounting

• High dynamics at low detent torque

• One-cable solution

• Electronic rating plate

Control and drive systems

SystemOne CM

|

CNC for cutting machine

LTI Motion GmbH

CNC for cutting machines

Its compact Integration of machine controller, suplly unit and multi-axis controller, along with completely new Standards when it comes to flexibility, safety, dynamics, precision and simplicity make the SystemOne CM stand out from the rest.

Are you ready to a revolutionary in your field?

Compactness:

• 40% space saving compared to multi-axis systems

• 75% space saving compared to single-axes

• Unique three-axis controller

• Supply unit with integrated 24 V power supply

Simplicity:

• Greatly reduced costs for assembly and installation

• Reduced cable lengths thanks to one-cable solution

• Central programming and parameterization with the MotionCenter tool

Functionality:

• Motion functions in accordance with PLCopen

• Robotics packages from handling to articulated arm

• CNC packages for laser, milling, grinding and eroding applications in development

Safety:

• Integrated safety control

• STO as standard in the axis controller

• Safe movements in the axis controller

• Safe area monitoring in the System

Dynamics & precision:

• ASIC LTI drive with high computing power

• Efficient control structures

• Compensation functions

• Monitor for controlling vibrating mechanisms

• Auto-tuning

andronic 3060

|

CNC for other machine

LTI Motion GmbH

CNC for other machines

Together with the ServoOne drive controllers, the CNC control andronic 3060 is a system that leaves nothing to be desired. High performance from the CNC control up to the drives with sufficient performance buffer to guarantee high dynamics and precision even with large data volumes.

Functionality and openness:

andronic 3060 features:

• Up to 16 simultaneously interpolating axes

• Compensation functions

• Real-time coordinate transformations

• Integration of hardware provided by the customer

• Interface for the connection of customer software

Laser control:

• Control of pulse and analog-controlled laser units

• Position synchronized pulse signals with a resolution time of 10ns

• Laser commands are programmed based on position

• Analog power setting (0-10V) can be interpolated within the contour.

Dynamics and precision:

• Higher computing power due to the dual processor architecture

• Very short block processing time of just 100 µs

• Dynamic look ahead buffer

• Pico-interpolation

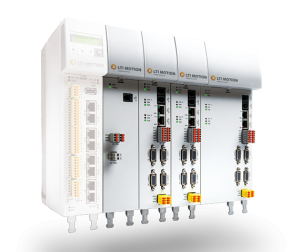

COconnect I/O

|

Other control and drive system

LTI Motion GmbH

Other control and drive systems

COconnect is the I/O system suitable for MotionOne. It contains analog and digital communication and encoder evaluation modules for automation solutions.

The modules can be connected directly to the MotionOne CP controller and can be operated remotely at any time with an EtherCAT bus coupler.

Functionality:

The I/O system can be flexibly used to generate automation solutions:

• Digital I/Os: 6, 8, 16 inputs per module; 8, 14 outputs

• Analog I/Os: 4, 4, 2/2 inputs/outputs

• Temperature measuring modules: 4, 6 inputs

• Communication modules: RS232 / 422, CANopen, Ethernet

• Encoder modules: 4 TTL / SSI

• The supply concept allows a central and secure shut down of the machine parts.

Durability:

The I/O modules comply with all EN 61131 standards.

Particular attention was paid to interference immunity and industry capability. Output modules are designed for the switching of inductive loads.

A standard galvanic separation in all modules increases the interference immunity and allows machine parts to be shut down.

ServoOne - multi-axis system

|

Other control and drive system

LTI Motion GmbH

Other control and drive systems

The drive solution in the power range from 2 to 450 A.

The modularity of the ServoOne family guarantees you optimum Integration into the machine process at all times.

A coordinated single-axis and energy-efficient multi-axis System meet the needs of any application across a wide power range. Whether a in high-speed field bus communication with the central multi-axis machine Controller or with distributed MotionControl intelligence in the drive controller - the ServoOne is a master of both.

The energy-efficient multi-axis system consists of DC-powered axis controllers and matched power supply units with sinusoidal mains power regeneration. A constantly controlled DC link voltage guarantees the independence of globally varying power supplies. Surplus kinetic braking energy is converted into electrical energy and sinusoidally -powered back into the supply grid, which protects the environment and saves costs.

• Axis controller 4 - 450 A rated current

• Overload factor up to 300 % at 4 kHz switching frequency

• DC link fuses integrated

• Power supply units with feed in power of 26 kW – 360 kW

Communication:

Field bus variety

The product range offers the flexible integration into the world of control and automation technology.

ServoOne provides a wide range of different field bus systems.

• Real-time Ethernet-based communication interfaces such as: EtherCAT, Sercos III, PROFINET IRT or PowerLink

• Sercos II + III as the established machine tool communication interfaces

• Proven field bus interfaces like CANopen based on DS301/DSP402 and PROFIBUS DP-V1 profiles complete the ServoOne field bus Portfolio

Safety:

Integral part of SO

STO (Safe Torque Off) integrated as Standard

• Acceptance up to SIL3 in accordance with IEC 61508 / IEC 62061 and PL e in accordance with EN ISO 13849

Optional safety control can be integrated into SIL3 / PL e

• Safe position or speed control with safety functions such as SS1/SS2, SOS, SLS, SLI, SLP

• Flexible and safe programming of the safety application

• Simple use of predefined safety sensors

• Implementation of complete machine safety solutions with safe cross communication with safety master in ServoOne

Dynamics and precision:

Impressive control technology for your machine

• High sampling rates of up to 16 kHz for optimal motor control

• Predictive pilot control structures for precise path accuracy

• Filter for damping mechanical vibrations

• Correction of encoder errors using patented GPOC procedure

• Compensation of motor cogging and friction torques

• Correction of mechanical spindle errors

• Autocommutation for synchronous motors without absolute value encoders

• Sensorless control of synchronous motors

ServoOne - single-axis system

|

Other control and drive system

LTI Motion GmbH

Other control and drive systems

The modularity of the ServoOne Family guarantees you optimum integration into the machine process at all times.

A coordinated single-axis and energy-efficient multi-axis system meet the needs of any application across a wider power range. Whether in high-speed field bus communication with the central multi-axis machine controller or with distributed MotionControl intelligence in the drive controller - the ServoOne is a master of both.

Thanks to its extremely wide power range, AC-powered ServoOne single-axis servocontroller can be used in a wide range of applications.

• 4 – 450 A rated current at 3 x 400 – 480 V AC power supply

• Overload factor up to 200 % at 8 kHz switching frequency

• 8 sizes for the optimal capacity gradation

• Integrated mains filter up to 72 A

• Cooling concepts:

- Air cooling

- Liquid cooling from 16 A

• Brake resistance can be integrated

- air-cooled up to 32 A

- water-cooled up to 450 A

Communication:

Field bus variety

The product range offers the flexible integration into the world of control and automation technology.

ServoOne provides a wide range of different field bus systems.

• Real-time Ethernet-based communication interfaces such as:

EtherCAT, Sercos III, PROFINET IRT or PowerLink

• Sercos II + III as the established communication interfaces in machine tools

• Proven field bus interfaces like CANopen based on DS301/DSP402 and PROFIBUS DP-V1 profiles complete the ServoOne field bus portfolio.

Safety:

Integral part of the SO

STO (Safe Torque Off) integrated as standard

• Certificate corresponding to SIL3 in accordance with IEC 61508 / IEC 62061 and PL e in accordance with EN ISO 13849

Optional safety control can be integrated into SIL3 / PL e

• Safe position or speed control with safety functions such as SS1 / SS2, SOS, SLS, SLI, SLP

• Flexible and safe programming of the safety application

• Simple use of predefined safety sensors

• Implementation of complete machine safety solutions with safe cross communication with safety master in ServoOne

Dynamics & precision:

Impressive control technology for your machine

• High sampling rates of up to 16 kHz for optimal motor control

• Predictive pilot control structures for precise path accuracy

• Filter for damping mechanical vibrations

• Correction of encoder errors using patented GPOC procedure

• Compensation of motor cogging and friction torques

• Correction of mechanical spindle errors

• Autocommutation for synchronous motors without absolute value encoders

• Sensorless control of synchronous motors

ServoOne CM

|

Other control and drive system

LTI Motion GmbH

Other control and drive systems

Compact multi-axis servocontroller

ServoOne CM is a drive system containing the following components, perfectly coordinated with each other:

• Supply unit

• Power supply for auxiliary voltage supply

• Single-Axis, two-axis and three-axis controllers

Compactness and simplicity:

75% more compact with ServoOne CM:

• 40 % space saving compared to multi-axis systems

• 75 % space saving compared to single-axes

• Unique three-axis controller

• Supply unit with integrated 24 V power supply

Everything is easy with ServoOne CM:

• Greatly reduced costs for assembly and installation

• Reduced cable lengths with one-cable solution

Safety:

Safe and secure – ServoOne CM:

• Safety control integrated into the axis controller

• STO as standard in the axis controller

• Safe movements in the axis controller

Dynamics and precision:

• ASIC LTI drive with high computing power

• Efficient control structures

• Compensation functions

• Monitor for controlling vibrating mechanisms

• Auto-tuning

ServoOne Safety

|

Other control and drive system

LTI Motion GmbH

Other control and drive systems

The ServoOne FS (Functional Safety) with integrated safety control offers the basis for efficient machine safety solutions thanks to its innovative features. In cooperation with LTI Motion’s highly experienced team, economical solutions, customized to their application, can be swiftly implemented.

Integrated safety control:

• Simple implementation of machine safety solutions

• Graphically programmable

• Certified function blocks

Safe cross-communication:

• Simple combination of up to 6 ServoOne FS

• Without costly parallel wiring

• Optimal use of I/O

Flexibility and speed:

Encoder flexibility:

• High encoder variance (Sin-Cos, Resolver, TTL, HTL)

• Safe evaluation of two encoders per axis for monitoring the mechanism

• Evaluation of a second encoder for monitoring another axis

Short response time:

• Two program tasks

• Fast channel

Simplicity:

Central data handling:

• Central data storage in the master

• Simple serial commissioning

• Validation support

Large range of safety functions:

• Safety functions in accordance with EN 61800-5-2

• Numerous special functions for simple application

• Predefined sensors

SMC1

|

safety control

LTI Motion GmbH

Other control and drive systems

The SMC1 product range provides a modular safety control for implementing machine safety solutions.

The safety control can be easily graphically programmed, parameterized and validated using the SafePLC programming interface.

Modularity:

The scalability of the SMC1 product range means that you will find the right safety control for every application.

• SMC1-Z10 (without axis monitoring)

• SMC1-Z2x, (1 axis monitoring)

• SMC1-Z3x, (2 axis monitoring)

• SMC1-Z40, (2 axis monitoring + safe analog IN)

I/O Expansion:

All SMC1 safety controls can be combined with up to two I/O expansion modules. These are easy to connect with each other via the back panel bus.

This means that solutions can be implemented with up to 58 safe inputs.

LeviSpin

|

CNC for cutting machine

LTI Motion GmbH

Spindle drives

The latest development in LTI Motion GmbH is a magnetic bearing drilling spindle with a HSK32 tool interface where the fluctuating shaft can be redirected and the frequency, amplitude and mode of vibration can be freely programed using the CNC control. This makes it possible to optimally adjust the chip size, chip shape, entry speed and entry angle of the cutting edge to the drilling process. Thanks to integrated sensor technology, important process data, for instance cutting power, can also be recorded and processed online to determine the drill wear. In addition, for example, the start of drilling or different material layers can be recognized, and the processing parameters can be flexibly adjusted during the process.

Your benefits:

• Increase in productivity (e.g. through higher feed and cutting speeds)

• Increase in quality by minimizing friction with very small chips

• Process optimization (e.g. rear-side deburring in a single process step)

• Intelligent process monitoring (e.g. tool wear detection)

Technical highlights:

• Magnetic bearing drilling spindle with “floating” shaft (no abrasion)

• Integrated sensor for intelligent monitoring of the process

• Adjustment of the processing parameters such as chip size, chip shape, entry speed and entry angle chip size, chip shape, entry speed and entry angle

Magnetic bearing spindles

|

Spindle drive

LTI Motion GmbH

Spindle drives

Complete solutions for challenging processing tasks

• Magnetic bearing spindle solutions for processing tasks with specific requirements

• Power in the multi-kilowatt range

• Speeds of up to 60,000 min-1

• Automatic tool clamping system

• Targeted periodic deflections of the shaft position are possible in radial and axial directions

• Integrated minimum lubrication (MQL)