Contact

Metal Work Deutschland GmbH

Rankinestraße 2 86899 Landsberg am Lech

Germany

Germany Route planner

Route planner

Enter the destination

Pin

Unpin

Pin

Unpin

A blog article has been published

2022-03-02

Pin

Unpin

Pin

Unpin

10 products have been added

2021-03-30

198

More information

155

More information

192

More information

153

More information

158

More information

188

More information

135

More information

Pin

Unpin

Pin

Unpin

8 products have been added

2021-03-30

146

More information

183

More information

179

More information

118

More information

100

More information

191

More information

Pin

Unpin

Pin

Unpin

3 products have been added

2021-03-26

Pin

Unpin

Pin

Unpin

2 products have been added

2021-03-25

130

More information

Pin

Unpin

Pin

Unpin

4 products have been added

2021-03-23

Pin

Unpin

Pin

Unpin

7 products have been added

2021-03-22

190

More information

160

More information

147

More information

123

More information

120

More information

Pin

Unpin

Pin

Unpin

A product has been added

2021-01-13

183

More information

Pin

Unpin

Pin

Unpin

Attended a fair

2020-02-12

Show more entries

Address

Gallery

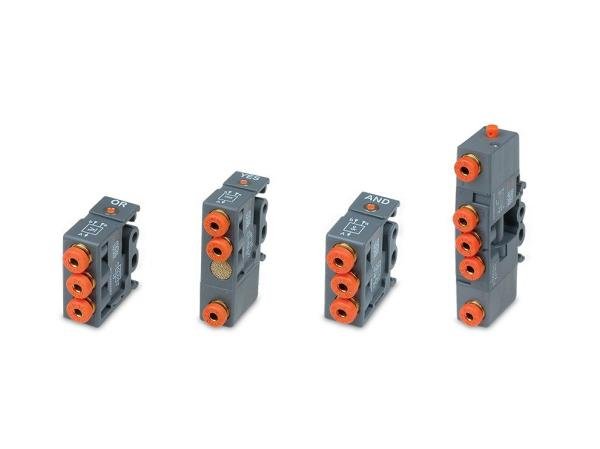

Fittings

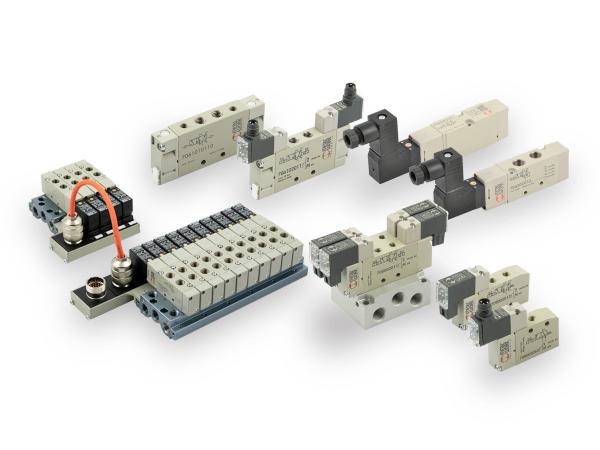

Valves

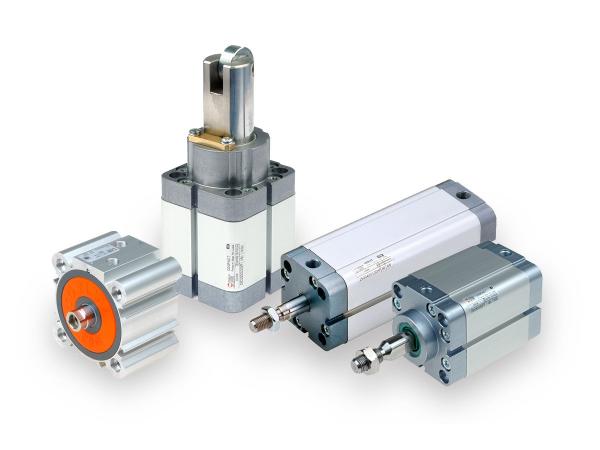

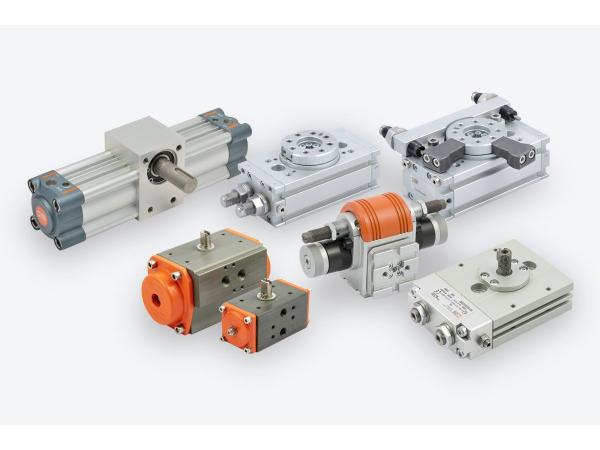

Actuators

Italy

Italy

Social Networks