MMC Hartmetall GmbH

Products

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

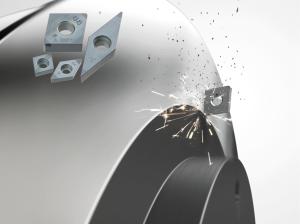

BC8100 - CBN Insert Series

For the efficient turning of high hardened steel, Mitsubishi Materials has an extensive range of coated CBN insert grades, the BC8100 series. Four grades make up the complete range:

BC8105 for the highest speeds and fine surface finishing. This grade can provide long tool life and fine surface finishes of Ra 0.6?m or better due to the improved lubricity of the CrAlN and TiAlN layered coating.

BC8110 is the first choice for continuous high speed and light interrupted machining up to 310 m/min cutting speeds.

BC8120 for general applications delivers a substantially better wear resistance and cutting edge toughness through use of a substrate with a new micro-particle binder that prevents crack development. This micro particle binder is also adopted across the whole 8100 series.

BC8130 is for the toughest workpieces and for heavily interrupted cutting. Peeling of the coating, usually caused by the impact of interrupted machining, is prevented by the adoption of a high CBN content substrate and a customised ceramic coating.

BC5110

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

Coated PCBN grade for grey cast iron.

Excellent wear resistance when turning grey cast irons at low cutting speeds.

Provides fine surface finishes on low rigidity workpieces.

Applications:

- For continuous cutting of grey cast iron materials

- For general applications

- For lower cutting speeds and low rigidity workpieces of grey cast iron materials

Features:

- For continuous cutting of grey cast iron materials

- For general applications

- For lower cutting speeds and low rigidity workpieces of grey cast iron materials

BC8200

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

BC8210 and BC8220 are the newest innovative PCBN grades for hard turning in continuous, light and medium interrupted cutting applications.

The new BC8220 and BC8210 grades exhibit excellent flank and crater wear resistance. Together with increased chipping resistance this provides more stable machining processes and enables long tool life over a wide range of high speed applications.

The new BR chipbreaker in combination with BC8220 was developed to provide the advantage of improved chip

control during high depth of cut machining.

The gold coated outer layer makes it easier for wear detection and easily defines used cutting edges.

MC5100 Series

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

CVD-coated grades for turning cast iron

from high speed turning to interrupted cut turning.

The process of casting iron enables complex geometries to be formed in the component that is produced. Different types of cast irons produce different chips when machined and can cause various types of damage to an insert. The complex shapes produced in castings also creates challenges because contact with the workpiece can suddenly change from continuous to interrupted cutting. In response to these challenges, Mitsubishi Materials has created a series of grades that are able to successfully machine all types of cast iron materials and component geometries.

MC6100 Series

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

MC6125 & MC6115 are the first recommendations for steel turning and are suitable for a wide range of continuous through to intermittent machining applications. By improving the existing technology, wear and fracture resistance and cutting edge stability have been dramatically increased.

Machine tools have become more powerful and efficient,

so to meet the demand of higher cutting speeds and to improve their machining efficiency, the MC6100 series of grades have been developed.

To respond to these demands for high efficiency, and also for use on conventional applications, MC6115 and MC6125, the latest CVD coated grades have been developed for turning steels at high speeds. They also provide improved cutting edge stability.

MH515

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

The MH515 CVD coated carbide grade was developed for machining of cast austenitic stainless steels and ductile cast iron, making it ideal for parts such as turbocharger housings. The new advanced coating improves adhesion to the carbide substrate to prevent plastic deformation of the cutting edge, therefore increasing tool life.

MP9000

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

The new MP9000?/?MT9000 turning insert grades have been developed for difficult-to-cut materials.

The 9000 series is divided into 2 types ? coated (MP) and uncoated (MT). All inserts are ground and available in different geometries. The latest technologies of the coated grades (MP) provide improved fracture and wear resistance. The uncoated grades (MT) with polished, sharp cutting edges provide long tool life when machining titanium alloys.

MS6015

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

The new MS6015 gains high marks for innovation due to the combination of the special carbide substrate and the new PVD coating. Ideal for outstanding performance when machining low carbon precision steel parts.

Reduced built-up edge and low wear guarantees minimal tolerance deviations.

MS7025

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

The MS7025 PVD coated carbide grade is suitable for low feed machining of small, high-precision parts. The dense nano-multi-layer coating suppresses damage that tends to occur during low feed machining and dramatically improves chip welding and wear resistance.

The market demand for improvement in machining accuracy is increasing because of the miniaturization of parts due to the digitalization of automobiles. The machining of workpiece materials where the speed and feed cannot be increased is growing. Especially the cases when machining with small automatic lathes where a low feed area is the main target, there are demands for tools that are capable of achieving these machining parameters.

MS9025

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

Improved cutting edge delivers next generation small parts machining.

The PVD coated MS9025 grade has improved thermal conductivity by optimising the grain size and reducing the boundary contact between the carbide particles. This optimisation reduces the temperature of the cutting edge during machining.

The even surface of the coating has been achieved by first making the carbide substrate smooth then by promoting straight growth of the coating crystals. This leads to excellent welding resistance. The high Al-rich (Al,Ti)N single layer coating provides stabilization of the high hardness phase and succeeds in dramatically improving wear, crater and welding resistance.