MMC Hartmetall GmbH

Products

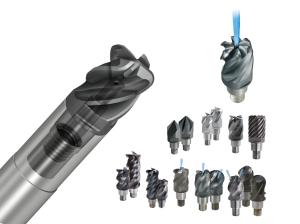

MINI DVAS

|

Drill

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Drills

Solid carbide Tristar drill series for fast, reliable and accurate drilling.

Mini DVAS ? High efficiency, long tool life, high precision.

The DVAS drills can peform at higher feeds and speeds meaning faster drilling cycles.

Straighter holes and improved dimensional accuracy

are enabled by using DVAS drills. The tool life exceeds

all normal expectations.

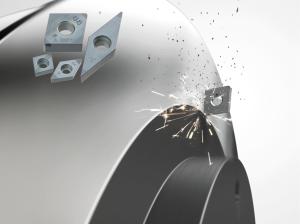

BC5110

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

Coated PCBN grade for grey cast iron.

Excellent wear resistance when turning grey cast irons at low cutting speeds.

Provides fine surface finishes on low rigidity workpieces.

Applications:

- For continuous cutting of grey cast iron materials

- For general applications

- For lower cutting speeds and low rigidity workpieces of grey cast iron materials

Features:

- For continuous cutting of grey cast iron materials

- For general applications

- For lower cutting speeds and low rigidity workpieces of grey cast iron materials

BC8200

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

BC8210 and BC8220 are the newest innovative PCBN grades for hard turning in continuous, light and medium interrupted cutting applications.

The new BC8220 and BC8210 grades exhibit excellent flank and crater wear resistance. Together with increased chipping resistance this provides more stable machining processes and enables long tool life over a wide range of high speed applications.

The new BR chipbreaker in combination with BC8220 was developed to provide the advantage of improved chip

control during high depth of cut machining.

The gold coated outer layer makes it easier for wear detection and easily defines used cutting edges.

MC5100 Series

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

CVD-coated grades for turning cast iron

from high speed turning to interrupted cut turning.

The process of casting iron enables complex geometries to be formed in the component that is produced. Different types of cast irons produce different chips when machined and can cause various types of damage to an insert. The complex shapes produced in castings also creates challenges because contact with the workpiece can suddenly change from continuous to interrupted cutting. In response to these challenges, Mitsubishi Materials has created a series of grades that are able to successfully machine all types of cast iron materials and component geometries.

MC6100 Series

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

MC6125 & MC6115 are the first recommendations for steel turning and are suitable for a wide range of continuous through to intermittent machining applications. By improving the existing technology, wear and fracture resistance and cutting edge stability have been dramatically increased.

Machine tools have become more powerful and efficient,

so to meet the demand of higher cutting speeds and to improve their machining efficiency, the MC6100 series of grades have been developed.

To respond to these demands for high efficiency, and also for use on conventional applications, MC6115 and MC6125, the latest CVD coated grades have been developed for turning steels at high speeds. They also provide improved cutting edge stability.

MH515

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

The MH515 CVD coated carbide grade was developed for machining of cast austenitic stainless steels and ductile cast iron, making it ideal for parts such as turbocharger housings. The new advanced coating improves adhesion to the carbide substrate to prevent plastic deformation of the cutting edge, therefore increasing tool life.

MP9000

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

The new MP9000?/?MT9000 turning insert grades have been developed for difficult-to-cut materials.

The 9000 series is divided into 2 types ? coated (MP) and uncoated (MT). All inserts are ground and available in different geometries. The latest technologies of the coated grades (MP) provide improved fracture and wear resistance. The uncoated grades (MT) with polished, sharp cutting edges provide long tool life when machining titanium alloys.

MS6015

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

The new MS6015 gains high marks for innovation due to the combination of the special carbide substrate and the new PVD coating. Ideal for outstanding performance when machining low carbon precision steel parts.

Reduced built-up edge and low wear guarantees minimal tolerance deviations.

MS7025

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

The MS7025 PVD coated carbide grade is suitable for low feed machining of small, high-precision parts. The dense nano-multi-layer coating suppresses damage that tends to occur during low feed machining and dramatically improves chip welding and wear resistance.

The market demand for improvement in machining accuracy is increasing because of the miniaturization of parts due to the digitalization of automobiles. The machining of workpiece materials where the speed and feed cannot be increased is growing. Especially the cases when machining with small automatic lathes where a low feed area is the main target, there are demands for tools that are capable of achieving these machining parameters.

MS9025

|

Insert for turning

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

Improved cutting edge delivers next generation small parts machining.

The PVD coated MS9025 grade has improved thermal conductivity by optimising the grain size and reducing the boundary contact between the carbide particles. This optimisation reduces the temperature of the cutting edge during machining.

The even surface of the coating has been achieved by first making the carbide substrate smooth then by promoting straight growth of the coating crystals. This leads to excellent welding resistance. The high Al-rich (Al,Ti)N single layer coating provides stabilization of the high hardness phase and succeeds in dramatically improving wear, crater and welding resistance.

WJX - Series

|

Surface milling tool

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Surface milling tools

Mitsubishi Materials has added 2 new sizes and a new insert grade to its recently launched WJX series of high feed cutters. WJX has been designed to be multi-functional and able to perform at high feed ates to ensure usability and efficiency across a wide choice of applications. To increase its capabilities, 2 maller diameters, 50 mm and 52 mm have been introduced, with the Ø50 being provided in both 3 and 4 tooth types.

Furthermore, a new grade of insert, MC7020, for high performance machining of steels and stainless steels has been added to expand the range of applications for the WJX series. The CVD coated MC7020 grade has been designed to suppress crater wear that occurs during high speed cutting, and helps to achieve process stability, especially in high efficiency machining conditions.

The high feed capability of this new cutter means it is ideal for rough machining under the demands of modern high efficiency conditions. WJX achieves stable machining and lowers cutting noise at high depths of cut and even during interrupted machining. This is due to its ability to reduce the cutting resistance generated at the initial point of contact between the insert and material.

Inserts

The double-sided negative inserts with the complex-shaped flank face provides excellent economy, increased sharpness and strength. The unique cutting edge geometry forms short chips and helps to prevent chip tangling to further enhance usability. To cope with the loads at high feed rates, the increased insert thickness provides the strength needed and helps to prevent sudden fracturing. Furthermore, a straight section of the cutting edge extends along the insert to enable high feed machining even at maximum depths of cut. The chip pocket area is left clear by use of a dovetail geometry that prevents the insert from lifting and provides stable clamping without the need to use a clamp bridge. In addition, the dovetail insert pocket geometry helps to absorb cutting forces. The cutting edge also has a small wiper face that provides good surface finishes for rough machining. Overall, the geometry of the inserts provides the best features of traditional single sided inserts, namely good ramping performance and sharpness, whilst also having the best double sided features of cost efficiency and strength.

Grades and sizes

MC7020 complements the eight different grades of

insert currently available and the new Ø50 and Ø52

adds to the existing Ø63-Ø160mm range.

WWX Series

|

Surface milling tool

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Surface milling tools

The WWX400 is MMC?s latest high performance 90° milling cutter with double-sided trigonal inserts. The precise positioning of the insert ensures a true 90° shoulder milling operation. The insert with six usable cutting edges ensures cost effectiveness thanks to a special negative geometry and also provides excellent machining reliability whilst maintaining a sharp cutting action.

VQ-Serie

|

End miller

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

End millers

A wide range of high-performance milling cutters:

VQ: High performance for difficult-to-machine materials

VQT6UR: Circular arc milling cutter for finishing titanium alloys

VQT5MVRB: Outstanding efficiency in milling deep grooves

Coolstar: Ideal for high productivity machining of stainless steel and titanium components.

Find out more. Download our brochure "VQ-B236" in the Product Details tab.

GW-Series

|

Indexable insert for grooving and parting

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Indexable inserts for grooving and parting

Mitsubishi Materials extensive range of high quality turning tools has been expanded to include a brand new series of grooving and parting-off tools, called GW.

Simple and efficient

Simplicity and efficiency; in addition to the pre-requisite high quality and performance, were the benchmarks defined during the design phase of the new GW series. The simplicity was taken care of by using the tool blade itself to clamp the insert without any screws. By using a unique wrench, it is possible to remove and replace the insert with one simple action, thereby making it efficient for everyday use in the workshop. Added security and rigidity is provided by the reverse taper geometry that prevents extraction during machining. The design also incorporates three large convex location faces for precise insert location epeatability, and in combination with a small location key, gives provision for increased reliability during machining.

Double through coolant holes

Two through coolant holes positioned close to the cutting edge simultaneously supply cutting fluid to the rake and flank faces. This provides effective cooling and lubrication for increased wear resistance that in turn provides the end user with longer tool life and lower costs. Up to 7MPa coolant pressure can be used to provide the best conditions for reducing heat generation.

Flexibility

There are 6 coolant ports on the tool block, facilitating easy input configuration for the coolant. Further flexibility and ease of use is provided by the elongated coolant outlet that feeds into the blade. The overhang length is also easily set by using the simple scale etched onto the blade. A wide range of overhang settings within the zone clearly marked on the tool block and blade can be fed with coolant via the elongated supply ports.

Performance and reliability

A range of applications and materials from alloy and stainless steels, plus cast irons through to difficult to cut materials are covered by four of Mitsubishis high tech coated grades. The versatile PVD coated VP20RT inserts are highly versatile and suitable for multi material use, thereby saving on inventory costs. Other grades, such as the MY5015 is for steels as well as cast iron machining up to 300m/min, whilst the VP10RT grade covers the harder range of steels, stainless steels, heat resistant and titanium alloys. Two different chipbreakers are offered, the GS type for both parting off and grooving, plus the GM type that specialises in high performance parting off. All inserts are available in widths from 2mm to 5mm.

VFR

|

Die sinking cutters

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Die sinking cutters

When it comes to the machining of hardened steel, Mitsubishi Materials already has a reputation that places the cutting tool manufacturer as the industry benchmark. Further cementing this market position, the company has now launched its new VFR Series of ball nosed end mills. Capable of machining extremely hard materials up to 70HRC, this next generation of end mills are manufactured from an ultra-micro grain carbide substrate that has an (AlTiSi)N sub-layer coating that enhances wear resistance and improves adhesion strength for significantly improved tool life. Added to the sub-layer is Mitsubishi?s newly developed AlCrSiN multi-layered PVD coating. This innovative new layer technology offers unsurpassed oxidation resistance, improved lubricity and higher wear resistance. The result is tool life performance that extends machine utilisation whilst providing customers with the confidence to run unmanned machining on the hardest materials for periods that far exceed that of competitor products.

Revolution? line that is suitable for machining hard materials from 50 to 70HRC, the new VFR Series gives end users a particularly wide application range for hard material machining. This makes the new VFR Series of ball nosed end mills the tool of choice for everything from rough to finish machining of hard materials. The VFR Series is available in two variants, the VFR2SBF for fine finish and mirror finish machining and the VFR2SB for rough, semi-finishing and finishing applications.

The VFR2SBF finishing tool incorporates Mitsubishi?s Zero-? surface technology and a unique radius geometry that demonstrates impressive centre cutting credentials whilst the polished 30 degree flute helix rapidly evacuates swarf. The two flute finishing ball nose has a short cut length for maximum rigidity that optimises performance when cutting carbon steel, alloy steel, pre-hardened steel and hardened steels. The finishing tool is available with a straight shank variant or a tapered shank for maximising access to difficult to reach geometries. The VFR2SBF is offered in diameters of 1 mm through to 6 mm diameters.

MPS1 - drill

|

Drill with MiRACLE SIGMA coating

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Drills

Increased performance in all parameters

MPS1 drills were developed to meet future technological standards. The innovative cutting edge geometry with the reworked four margin flute design improves hole concentricity and surface finish. The newly designed straighter cutting edge together with MIRACLE SIGMA coating enables smoother penetration at the highest feeds and speeds, thereby increasing overall productivity. Mitsubishi Materials TRI-COOLANT technology provides optimised lubrication at the cutting point of the drill, offering reliability and increased performance under demanding machining conditions. In addition MQL drilling is possible with the MPS1 drill and is a suitable way to increase cost efficiencies. MPS1 drills can be used for multiple applications and materials and are ideal for steels, cast iron and stainless steels.

MVX: Indexable Drill for Drilling Depth up to 6xD

|

Indexable Drill for Drilling Depth up to 6xD

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Drills

Increased performance and maximised drilling depth up to 6xD

- Economical insert with 4 cutting edges

- Strong body for high performance drilling

- One insert type for external and internal pocket

The MVX high performance indexable insert drill has an exclusively robust body with through coolant holes. The inner and outer inserts are interchangeable PVD and CVD coated types with 4 cutting edges. In addition to standard holes, MVX has been specifically developed to accurately penetrate partially angled surfaces. The unique wavy chipbreaker design of the inserts provide optimised chip control across various hole depths from 2xD and 3xD up to 6xD. The innovative MIRACLE SIGMA coating substrate offers superior tool life and an excellent resistance to chip welding at high speeds and feeds. This smart technology synergy offers process reliability and increased levels of productivity and ensures the MVX drill is ideal for the high performance machining of steels, stainless steels and cast iron.

BC8100 - CBN Insert Series

|

Coated CBN Grade for High Hardened Steel Applications

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Inserts for turning

For the efficient turning of high hardened steel, Mitsubishi Materials has an extensive range of coated CBN insert grades, the BC8100 series. Four grades make up the complete range:

BC8105 for the highest speeds and fine surface finishing. This grade can provide long tool life and fine surface finishes of Ra 0.6?m or better due to the improved lubricity of the CrAlN and TiAlN layered coating.

BC8110 is the first choice for continuous high speed and light interrupted machining up to 310 m/min cutting speeds.

BC8120 for general applications delivers a substantially better wear resistance and cutting edge toughness through use of a substrate with a new micro-particle binder that prevents crack development. This micro particle binder is also adopted across the whole 8100 series.

BC8130 is for the toughest workpieces and for heavily interrupted cutting. Peeling of the coating, usually caused by the impact of interrupted machining, is prevented by the adoption of a high CBN content substrate and a customised ceramic coating.

WSX445

|

Low Cutting Resistance Face Mill

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Surface milling tools

The WSX445 face mill is a next generation of face milling cutter and has been designed to elevate the performance level when machining steels, cast iron and stainless steels, as well as nickel based and titanium alloys. Embracing the latest MIRACLE SIGMA technology WSX445 uses inserts with advanced cutting materials, new geometries and coatings. Compared to conventional milling cutters, WSX445 uses unique double sided inserts instead of the standard single sided types. This means there are 8 fully functional cutting edges on each insert and are available in various chipbreaker geometries. This intelligent synergy ensures economically efficient production processes and added value for users without any loss in surface finish quality whilst also maintaining the required smooth cutting action for overall high Performance.

iMX - End Mill System

|

End miller

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

End millers

Smart milling for high end use.

- Ecological and flexible high Performance milling

- Heads for steel, stainless steel, Aluminium, and super alloys

- Excellent in Long overhang milling

The exchangeable end mill system iMX is one of the most innovative and flexible solutions and was developed to cater for a wide application area. The smart combination of the solid carbide screw-in heads, offered in 12 different geometries, and the solid carbide holders offers the highest levels of precision, stability and productivity levels, especially for deep pocketing and long overhang applications. The exchangeable heads have the latest MIRACLE SIGMA coating that offers a higher wear resistance and the maximum level of tool life for machining titanium alloys, stainless steels and other difficult to cut materials. Geometries are also available for machining carbon and hardened steels as well as aluminium alloys. The holders and selected head types have through coolant capability ensuring optimum chip removal and cooling.

GY - TRIFORCE-System

|

High performance grooving system

MMC Hartmetall GmbH - A Sales Company of Mitsubishi Materials

Indexable inserts for grooving and parting

High rigidity and accuracy for stable grooving applications

- High rigidity and accuracy

- Flexible due to modular blades

- Great selection of sizes, grades and chip breakers

The TriForce grooving system is a new series of innovative grooving tools designed to offer ultimate rigidity and accuracy for stable grooving applications. The modular system allows a variable tool selection whilst maintaining the important, overall rigidity and clamping strength. Additionally, a wide variety of inserts for the TRIFORCE range makes it possible to cover a diverse area of machining applications, ensuring high efficiency, precision machining.

TriForce system of clamping

The pioneering clamping system ensures that the cost efficient modular blade is securely located from 3 directions, side, front and top. This leads to high tool rigidity, comparable to a mono block type holder and able to produce results of equal quality.

Additionally, the modular system improves tool management by reducing stock of costly mono block holders and has the benefit that one tool holder can be used with several different blades. These blades are interchangeable so that different lengths can be used for different applications and also if tool breakage occurs, it is only necessary to change the blade, making it economically advantageous over a mono block types.