26. November 2018

SUCCESSFUL WORKSHOPS

Okuma provides know-how about cutting-edge technologies

CNC machine tool manufacturer Okuma welcomed visitors at the Technical Centre South in Langenau, Germany, and at the Technical Centre East in Parndorf, Austria.

During the workshops, international visitors were introduced to Okuma’s Premium Solutions that allow for process-intensive manufacturing methods, improved productivity or easy and efficient measuring and compensation. Live demonstrations provided clear examples of how processes could be optimised. The Okuma Technical Centres (OTC) are open to manufacturers around the world. Various hardware and software solutions are on display at the centres. Okuma engineers, service and sales experts are happy to discuss customer-specific requirements and options with visitors.

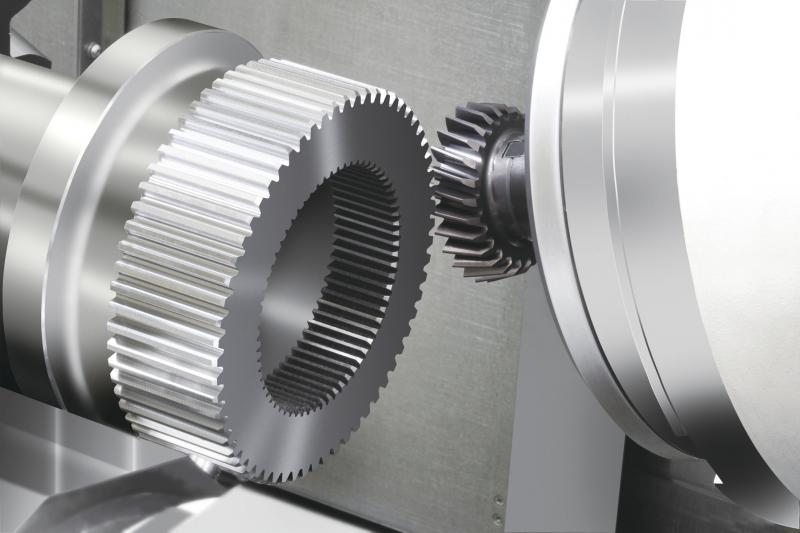

Advanced gear manufacturing and 3D gauging

Okuma’s Gear Manufacturing Package presented at the workshop allows for highly productive manufacturing of gears on multitasking machines or 5-axis machining centres. As the package includes turning, milling, skiving and hobbing in one machine, all necessary manufacturing steps can be completed within one setup.

Using NC Gage, gauging becomes easy and efficient. As the gage measures workpieces while they are mounted in a multitasking machine, additional setups for measuring procedures become obsolete. Also, changing the workpieces’ posture during measuring is not necessary as the gage moves while gauging.

Next level threading and turning

Multiple Premium Solutions improve and support threading operations. Variable Spindle Speed Threading for example optimises threading of long threads. By adjusting spindle speeds when the tool reaches critical areas of the workpiece, the solution avoids harmonic problems and suppresses chatter. Threads with excellent surface quality are the result.

Okuma’s Turn-Cut is a real game changer when it comes to turning unbalanced and asymmetric workpieces. Instead of rotating the workpiece, the application turns the machining centre’s tool inside or around the workpiece. In this way, the solution not only enables turning operations on a machining centre but also allows for achieving various hole diameters using one tool. The solution therefore opens entirely new possibilities for manufacturers and increases productivity.

Germany

Germany