Okuma Europe GmbH

Products

Portal milling machines

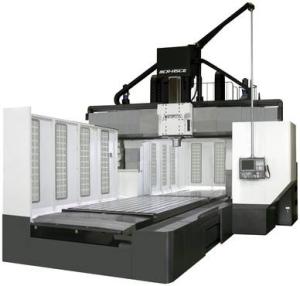

MCR-A5CII

|

Double Columns

Okuma Europe GmbH

Portal milling machines

| 2.150 - 3.650 | |

| 1.500 x 3.000 - 3.000 x 12.000 | |

| 3.200/2.600/800 - 12.200/4.100/1.200 | |

| 4.000 [6.000, 10.000] | |

| 50 [80, 100, 120, 180] | |

| 26/22 [30/22] | |

| 30/32/20 | |

| 6.180 x 8.430 - 7.780 x 28.420 |

The MCR-A5CII is a high-speed double column machining center with compact auto loading/unloading attachments for true 5-sided machining in a compact footprint. The solid double column construction ensures greater rigidity and closer tolerances, making this machine well-suited for the efficient machining of general parts and rapid die/mould jobs.

MCR-BIII

|

Double Columns

Okuma Europe GmbH

Portal milling machines

| 2.050 - 3.550 | |

| 2.800 x 1.500 - 3.000 x 11.800 | |

| 3.000/2.700/800 - 12.000/4.200/1.300 | |

| 4.000 [3.600, 6.000, 8.000, 10.000] | |

| 32 [50, 72, 100, 120, 180] | |

| 30/22 [45/37, 26/22] | |

| 15/20/15 | |

| 6.995 x 8.200 - 8.780 x 27.400 |

The Okuma MCR-BIII double column machining center provides five-face machining of parts in a single, economical and efficient setup. The ram-type head features a 30 kW, 4.000 min vertical spindle for powerful cutting and rigidity. A wide variety of machining, including angular and compound angular surface machining, can be performed automatically with a single workpiece setup through the use of various attachments. Automatic tool changing to the vertical spindle or to the horizontal attachment is provided with a standard 50 tool magazine located on the side of the column, with additional tool chain capacities optional. The MCR-BIII is versatile enough to handle everything from heavy cutting to high-accuracy finishing of die/mould jobs and large, complex parts.

MCR-C

|

Double Columns

Okuma Europe GmbH

Portal milling machines

| 2.650 - 3.650 | |

| 2.000 x 4.000 - 3.000 x 12.000 | |

| 4.200/3.200/1.050 - 12.200/4.200/1.250 | |

| 4.000 [6.000] | |

| 50 [80, 100, 120, 180] | |

| 45/37 | |

| 24/24/15 | |

| 7.810 x 10.730 - 8.710 x 28.420 |

The MCR-C double column machining center was created to meet the demand of heavy industries for high power, high torque and high productivity. The exceptionally rigid spindle delivers powerful, 5-axis cutting on a thermally stable machine that provides efficient and accurate machining of large components. The MCR-C double column machining center’s auto tool changer (ATC) and full array of available spindle heads (attachments) support the machining of all types and shapes of parts.

MCR-S

|

Double Columns

Okuma Europe GmbH

Portal milling machines

| 2,000 × 4,000 to 2,500 × 6,500 | |

| 2,650 to 3,150 | |

| 30 to 10,000 | |

| 50, 80, 100, 120, 180 | |

| 26/22 | |

| X: 30 / Y: 32 / Z: 15 | |

| X: 4,200 / Y: 3,200 / Z: 800 / W: 1,000 to X: 6,700 / Y: 3,700 / Z: 800 / W: 1,200 | |

| 7,370 × 10,730 / 12,830 / 16,430, 7,870 ×10,730 / 12,830 / 16,430 |

The MCR-S is a high-speed, high-quality double column machining centre that offers outstanding dimensional accuracy and surface quality for press die manufacturing. The exceptionally rigid spindle delivers powerful, 5-axis cutting on a thermally stable machine that provides efficient and accurate machining of large components. The machine’s structural design achieves fastest-class continuous feed rates and reduces cycle time by 25 percent compared to previous models.

MCV-AII

|

Double Columns

Okuma Europe GmbH

Portal milling machines

| 1.650 - 2.050 | |

| 1.200 x 2.100 - 1.500 x 5.100 | |

| 2.000/ 1.600 / 1.000 - 5.000/ 2.000/ 1.150 | |

| 4.000 [6.000, 10.000] | |

| 24 [50, 72, 100] | |

| 22/18,5 [22/15] | |

| 20/20/10 | |

| 4.740 x 6.000 - 5.140 x 12.200 |

The MCV-AII delivers smooth performance with the speed and power you expect from an Okuma double column machining center. This machine is perfect for streamlined machining of medium to large parts from heavy-duty cutting to fast finishing. The direct (gearless) spindle drive means less noise for better work environment and less vibration for longer tool life. Standard spindle cooler delivers consistently high accuracies while the solid double-column construction ensures flawless precision and rigidity.