Quinx

Products

Quinx AG

Manufacturing execution software (MES)

MDC 4000

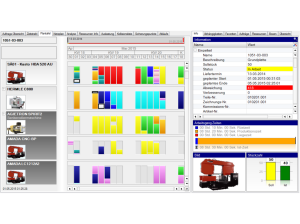

ProVis stands for «Production Visualisation» and is a modern MDC (Manufacturing Data

Collection) system that has been developed in object-oriented system architecture with a

graphical user interface and state-of-the-art client/server technology.

Today, a machine 'knows' which order it is currently processing, how quickly it is producing and what malfunctions are occurring. With the manufacturing data collection MDC 4000 from Quinx AG, the production data is collected, processed and made available to the relevant person in real time. For this reason, an the MDC 4000 serves many other applications: Maintenance, tool management, CAQ, energy management etc.

Customer's benefit:

- Reduction of the throughput times and delivery times

- Optimization of capacity and resource utilization

- Increase the productivity

- Optimisation of preventive maintenance and tool management

A standard interface such as OPC UA or MTConnect facilitates the direct readout of data from a controller. A wide variety of data can be recorded and evaluated. Quinx AG can directly connect various machine controls. With simple on-site tests, we check where this is possible without the support of the machine manufacturer. Information such as "machine running" or the number of pieces produced can also be collected most cost-effectively via an IO module.

JOBDISPO MES

|

Software for capacity and production scheduling

Quinx AG

Manufacturing execution software (MES)

Dynamic planning and scheduling based on real manufacturing data in real-time.

JOBDISPO MES automatically re-calculates and optimize the planning of hundreds of orders after a manual change of one single order within seconds. The consequence for each order is immediately visible and shown in a table. JOBDISPO fills up free capacity automatically. There is no manual work needed. You define and chose the algorithm how the system shall plan.

Customer's benefit:

- Drag & drop job order planning

- Automated scheduling algorithms

- Capapcity bottlenecks are displayed immediately

- Multilevel planning for complex projects

- Simulations, planning scenarios and analyses

- Interface to any kind of MRP

- MDC-Integration

-