Reishauer

Products

Reishauer AG

Gear grinding machines

Continous Generating Gear Grinding Machine RZ 126 4.0

Regarding productivity, the RZ 126 4.0 grinding machine sets industry standards in the high volume production of gears, and in its field, is the fastest machine on the market. Grinding speed (max.) 100 m/s The RZ 126 4.0 builds and expands on Reishauer?s successful twin-spindle machine concept. The machine combines the speed and productivity of the RZ 60 4.0 with the flexibility and the latest grinding technologies of the RZ 160 4.0 und RZ 260 4.0. Flexibility and Productivity The design principle embodies the uncompromising reduction of non-productive time by the twin-spindle technology, the short reaction time of the spindle drives and the high grinding speeds.

Continuous Generating Gear Grinding Machine RZ 1000

|

Gear grinding machine

Reishauer AG

Gear grinding machines

Big, but no job too small The RZ 1000 gear grinding machine combines universality, high precision and robust material removal rates. This machine embodies state-of-the-art gear grinding technologies. Furthermore, as the grinding oil flow is completely separated from the machine bed, it features extraordinary thermal stability.

Continuous Generating Gear Grinding Machine RZ 160 4.0

|

Gear grinding machine

Reishauer AG

Gear grinding machines

The Automotive Gear Grinding Machine The machine that can handle all the gears that are used in automotive transmissions. The RZ 160 4.0 gear grinder?s productivity sets the industrial standard for the production of automotive gears. Its working range diameter of up to 160 mm and its module range of 0.5 to 4 covers all gears, disk-type or shaft-type parts that are used in automotive transmissions.

Continuous Generating Gear Grinding Machine RZ 260 4.0

|

Gear grinding machine

Reishauer AG

Gear grinding machines

From automotive ring-gears to gears for medium-sized trucks The RZ 260 4.0 gear grinding machine covers the largest range of workpieces for the automotive industry. This includes all gears for car transmissions and gears of medium-sized trucks, ranging in diameter from 0 to 260 mm, and from module 0.5 to 5 mm.

Continuous Generating Gear Grinding Machine RZ 410

|

Gear grinding machine

Reishauer AG

Gear grinding machines

The Job Shop Machine The RZ 410 gear grinding machine combines universality, high precision and robust material removal rates. This machine represents state-of-the-art gear grinding technologies. As the grinding oil flow is completely separated from the machine bed, it features extraordinary thermal stability.

Continuous Generating Gear Grinding Machine RZ 550

|

Gear grinding machine

Reishauer AG

Gear grinding machines

Adding value to your gears The RZ 550 gear grinding machine combines universality, high precision and robust material removal rates. This machine embodies state-of-the-art gear grinding technologies. Furthermore, as the grinding oil flow is completely separated from the machine bed, it features extraordinary thermal stability.

Generating Grinding Machine RZ 126/160 KWS 4.0

|

Gear grinding machine

Reishauer AG

Gear grinding machines

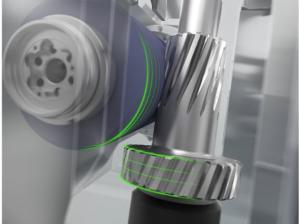

Grinding parts with interfering contours The Reishauer KWS series, featuring small diameter grinding worms, has enabled us to keep pace with the rapidly expanding electric mobility market. In this way, we have created further opportunities for our customers who require efficient high-volume production of high-precision gearing with collision-critical workpieces. Ensures the productivity advantages of continuous generating grinding If you look at processing times, generating gear grinding is superior to discontinuous grinding processes in practically all respects. In particular, the design of the grinding machine with two workpiece spindles enables loading to take place without affecting primary machining time. This can significantly shorten grinding cycles and thus achieve low unit costs. To keep providing you with the productivity of generating grinding with Reishauer level quality and precision, we have further developed two variants from our proven Reishauer 4.0 model series. Both the RZ 126 KWS 4.0 and the RZ 160 KWS 4.0, the latter designed for larger workpieces, enable efficient generating grinding of gears with interfering contours.

Vorsatzspindel KWS

|

Gear grinding machine

Reishauer AG

Gear grinding machines

Upgrade module for maximum flexibility

The KWS attachment spindle extends the range of services, especially for companies that want to cover a broader spectrum of gearings with just a few machines, and offers new possibilities while maintaining the same working range.

Maximum flexibility on one machine

The upgrade module for the Reishauer RZ 410 to RZ 1000 uses a corundum grinding worm with a reduced diameter of 140 mm (df min 67 mm), making the advantages of the generating grinding process available for extended applications. It fills the gap between our highly productive double spindle models RZ 126 / 160 KWS 4.0 and the profile grinding process. Translated with DeepL

The KWS attachment spindle extends the range of services, especially for companies that want to cover a broader spectrum of gearings with just a few machines, and offers new possibilities while maintaining the same working range.

Maximum flexibility on one machine

The upgrade module for the Reishauer RZ 410 to RZ 1000 uses a corundum grinding worm with a reduced diameter of 140 mm (df min 67 mm), making the advantages of the generating grinding process available for extended applications. It fills the gap between our highly productive double spindle models RZ 126 / 160 KWS 4.0 and the profile grinding process. Translated with DeepL