ROEMHELD

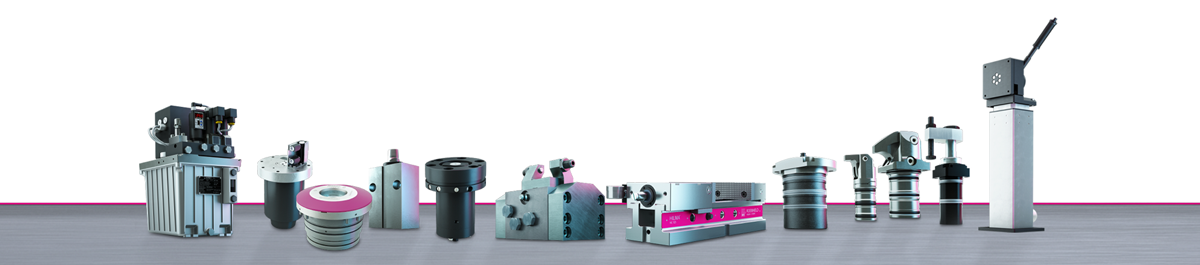

Products

Your solution provider in clamping and handling technology

ROEMHELD

Chucking systems

STARK.basic

| 88 bis 55.000 N | |

| < 0,01 mm |

STARK.basic

Pneumatic single acting

The fast closing clamps of the STARK.basic product family are zero point clamping systems with a wide range of applications. STARK.basic are used for installation in machine pallets, plates, angles, cubes, towers and swing bridges. Can be used for all common machining operations such as milling, turning, grinding, eroding as well as on test benches for assembly fixtures. The fast closing clamps made of high-quality tool steel are clamped mechanically and released pneumatically.

Special features of the STARK.basic product family

- Simple: modular design

- Economic: simple assembly and installation

- Price-conscious: cost effective entry-level models

- Compact: smallest STARK zero point clamping system

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

Pneumatic single acting

The fast closing clamps of the STARK.basic product family are zero point clamping systems with a wide range of applications. STARK.basic are used for installation in machine pallets, plates, angles, cubes, towers and swing bridges. Can be used for all common machining operations such as milling, turning, grinding, eroding as well as on test benches for assembly fixtures. The fast closing clamps made of high-quality tool steel are clamped mechanically and released pneumatically.

Special features of the STARK.basic product family

- Simple: modular design

- Economic: simple assembly and installation

- Price-conscious: cost effective entry-level models

- Compact: smallest STARK zero point clamping system

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

HILMA.TS

|

Tower workholding sytems

ROEMHELD

Chucking systems

| 100 und 125 mm | |

| 4 | |

| 25 kN | |

| 40 kN |

HILMA.TS Workholding System

- clamping against the fixed jaw

- HILMA.TS with 4 clamping sides

HILMA.TS TriStar with 3 clamping sides

- mechanically operated

- jaw widths 100 and 125 mm

Application

HILMA.TS tower workholding systems are used on horizontal machining centres, in vertical machining in connection with 4th axis, but also on 5-axis machining centres. The applications range from manually equipped machines to pallet stations and fully automated systems.

Description

The tower workholding systems HILMA.TS convince with their durability and precision. The patented guidance and sealing principle works without any delicate sheet metal covers or plastic wipers. The design as a monoblock, without interfaces to individually screwed workholding systems, stands for high stability and high accuracy. The centrally arranged fixed jaw as a central jaw is without load and thus absolutely zero point stable. The workpieces are positioned close to each other, thus reducing the travel paths of the machining centre to a minimum. The purely mechanical operation enables clamping also with low and always reproducible clamping forces. These characteristics turn the tower workholding systems HILMA.TS into a flexible standard fixture for a wide variety of applications in modern production.

Advantages

- 2 sizes for optimum design to the machining centre

- Clamping of 4, 8 or 16 workpieces with standard jaws

- Clamping of different workpiece dimensions also on one side

- Purely mechanical build up of the clamping force

- Easy and safe operation

- Large jaw openings and high flexibility due to extensive range of clamping jaws

- Highest stability by design as a monoblock

- Optimum protection against contamination and wear through patented guidance and sealing

- Process-safe application of clamping force, also when using grip jaws

Handling

The pneumatic clamping unit greatly improves the operating facility to an unrivalled extent. The operator triggers the clamping and unclamping process by actuating a foot-operated switch. Thus, he can use both hands for handling workpieces, which is especially important in the case of heavy workpieces. The torque for clamping the clamping system HILMA.TS must not be applied manually. The pneumatic screwdriver which has almost no weight, is suspended from two balancers and can be freely moved. The pneumatic clamping unit combines the reliable and simple mechanical features of the clamping system HILMA.TS with the user friendliness provided by a hydraulic system. The clamping system HILMA.TS can also be used in automated processes.

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

- clamping against the fixed jaw

- HILMA.TS with 4 clamping sides

HILMA.TS TriStar with 3 clamping sides

- mechanically operated

- jaw widths 100 and 125 mm

Application

HILMA.TS tower workholding systems are used on horizontal machining centres, in vertical machining in connection with 4th axis, but also on 5-axis machining centres. The applications range from manually equipped machines to pallet stations and fully automated systems.

Description

The tower workholding systems HILMA.TS convince with their durability and precision. The patented guidance and sealing principle works without any delicate sheet metal covers or plastic wipers. The design as a monoblock, without interfaces to individually screwed workholding systems, stands for high stability and high accuracy. The centrally arranged fixed jaw as a central jaw is without load and thus absolutely zero point stable. The workpieces are positioned close to each other, thus reducing the travel paths of the machining centre to a minimum. The purely mechanical operation enables clamping also with low and always reproducible clamping forces. These characteristics turn the tower workholding systems HILMA.TS into a flexible standard fixture for a wide variety of applications in modern production.

Advantages

- 2 sizes for optimum design to the machining centre

- Clamping of 4, 8 or 16 workpieces with standard jaws

- Clamping of different workpiece dimensions also on one side

- Purely mechanical build up of the clamping force

- Easy and safe operation

- Large jaw openings and high flexibility due to extensive range of clamping jaws

- Highest stability by design as a monoblock

- Optimum protection against contamination and wear through patented guidance and sealing

- Process-safe application of clamping force, also when using grip jaws

Handling

The pneumatic clamping unit greatly improves the operating facility to an unrivalled extent. The operator triggers the clamping and unclamping process by actuating a foot-operated switch. Thus, he can use both hands for handling workpieces, which is especially important in the case of heavy workpieces. The torque for clamping the clamping system HILMA.TS must not be applied manually. The pneumatic screwdriver which has almost no weight, is suspended from two balancers and can be freely moved. The pneumatic clamping unit combines the reliable and simple mechanical features of the clamping system HILMA.TS with the user friendliness provided by a hydraulic system. The clamping system HILMA.TS can also be used in automated processes.

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

STARK.connect

|

Zero point clamping system

ROEMHELD

Chucking systems

STARK.connect

Single and double acting, pneumatic

The STARK.connect series consists of fast closing clamps made of high-quality tool steel and housings made of anodised, high-strength aluminium with very small space requirements due to compact external dimensions. The system is mechanically tensioned with springs, pneumatically powerenhanced and also pneumatically released. The integrated spring assembly makes the STARK.connect self-locking.

Special features of the STARK.connect product family:

- Process-reliable: Industry 4.0 ready

- Flexible: various equalising options

- Ideal: active insertion despite small design

- Robust: high level of resilience

- Fast: very short clamping/release time

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

Single and double acting, pneumatic

The STARK.connect series consists of fast closing clamps made of high-quality tool steel and housings made of anodised, high-strength aluminium with very small space requirements due to compact external dimensions. The system is mechanically tensioned with springs, pneumatically powerenhanced and also pneumatically released. The integrated spring assembly makes the STARK.connect self-locking.

Special features of the STARK.connect product family:

- Process-reliable: Industry 4.0 ready

- Flexible: various equalising options

- Ideal: active insertion despite small design

- Robust: high level of resilience

- Fast: very short clamping/release time

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!