ROEMHELD

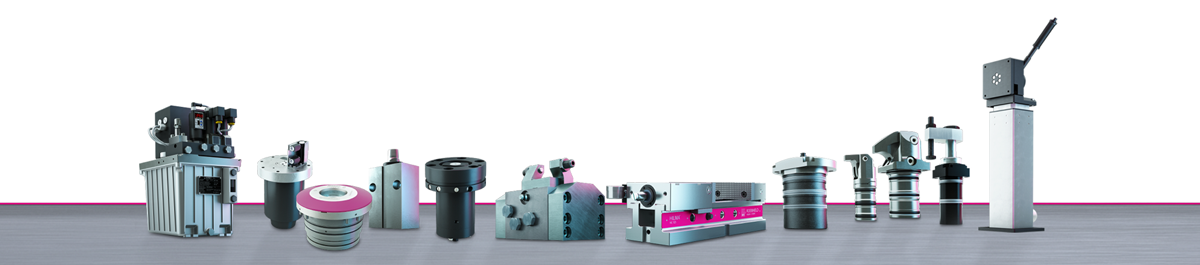

Products

Your solution provider in clamping and handling technology

ROEMHELD

Clamping devices, hydraulic

Hydraulic hinge clamps

Hinge clamps

- with metallic wiper edge and optional position monitoring

- double acting, max. operating pressure 250 bar

The hinge clamp is a low-cost hydraulic clamping element with many installation and connecting possibilities. If the clamping lever is completely retracted, unimpeded loading and unloading of the fixture can be effected.

A clamping recess in the workpiece a little bit wider than the clamping lever is sufficient as clamping surface. The special kinematics allow clamping nearly without side loads of workpieces which are very sensitive against deformation.

When pressurising the element, the piston moves upwards and swivels the clamping lever over the hinges forwards and at the same time downwards onto the workpiece. The piston force is deviated by 180° and is available as clamping force with virtually no loss of efficiency.

If the level of the clamping surface is exactly in the centre of the clamping range, no side loads are introduced into the workpiece.

The bodies are recessible in the fixture up to the flange. Alternatively intermediate plates are available for height adjustment.

All versions are optionally available with extended piston rod and with inductive or pneumatic position monitoring.

Discover our extensive product range at www.roemheld.de/en!

- with metallic wiper edge and optional position monitoring

- double acting, max. operating pressure 250 bar

The hinge clamp is a low-cost hydraulic clamping element with many installation and connecting possibilities. If the clamping lever is completely retracted, unimpeded loading and unloading of the fixture can be effected.

A clamping recess in the workpiece a little bit wider than the clamping lever is sufficient as clamping surface. The special kinematics allow clamping nearly without side loads of workpieces which are very sensitive against deformation.

When pressurising the element, the piston moves upwards and swivels the clamping lever over the hinges forwards and at the same time downwards onto the workpiece. The piston force is deviated by 180° and is available as clamping force with virtually no loss of efficiency.

If the level of the clamping surface is exactly in the centre of the clamping range, no side loads are introduced into the workpiece.

The bodies are recessible in the fixture up to the flange. Alternatively intermediate plates are available for height adjustment.

All versions are optionally available with extended piston rod and with inductive or pneumatic position monitoring.

Discover our extensive product range at www.roemheld.de/en!

Block cylinder S

|

Clamping device, hydraulic

ROEMHELD

Clamping devices, hydraulic

Block cylinder S

- double acting

- max. operating pressure 250 bar and 500 bar

- use as punching cylinder max. 250 bar

Hydraulic block cylinders are universally used for all linear movements with high force requirements and very small dimensions. The block cylinder S can withstand high mechanical and thermal loads.

Its preferred applications are:

Punching (Max. operating pressure 250 bar *)

Deburring

Forming such as bending, riveting, stamping

In mould making for actuating core pullers and slides

In automatic manufacturing systems with very short cycle times

The double-acting function ensures high function safety as well as exactly calculable and repeatable stroke times.

The block cylinders S are equipped with the latest sealing technology, so that optimally adapted versions are available depending on the operating pressure (250 or 500 bar), temperature and hydraulic fluid. At the piston rod outlet, the dirt wipers are largely protected against swarf by the recessed installation.

All series are equipped with piston and rod guide rings which absorb side loads between the sliding components and prevent direct metal contact.

This increases the service life and minimizes leakage. The admissible piston side load depends on the stroke and can be taken from the diagrams on page 5 of the catalogue sheet. The internal piston stops are of sturdy design. The admissible piston speed depends on the mass fixed to the piston and can be read in the diagram on page 5 of the catalogue sheet.

*) Maximum operating pressure 250 bar Required for punching applications due to the high load caused by the cutting impact. Even with the high-pressure version (500 bar), the pressure must be limited to 250 bar. The advantage of this is the longer service life of the high-pressure seals.

Discover our extensive product range at www.roemheld.de/en!

- double acting

- max. operating pressure 250 bar and 500 bar

- use as punching cylinder max. 250 bar

Hydraulic block cylinders are universally used for all linear movements with high force requirements and very small dimensions. The block cylinder S can withstand high mechanical and thermal loads.

Its preferred applications are:

Punching (Max. operating pressure 250 bar *)

Deburring

Forming such as bending, riveting, stamping

In mould making for actuating core pullers and slides

In automatic manufacturing systems with very short cycle times

The double-acting function ensures high function safety as well as exactly calculable and repeatable stroke times.

The block cylinders S are equipped with the latest sealing technology, so that optimally adapted versions are available depending on the operating pressure (250 or 500 bar), temperature and hydraulic fluid. At the piston rod outlet, the dirt wipers are largely protected against swarf by the recessed installation.

All series are equipped with piston and rod guide rings which absorb side loads between the sliding components and prevent direct metal contact.

This increases the service life and minimizes leakage. The admissible piston side load depends on the stroke and can be taken from the diagrams on page 5 of the catalogue sheet. The internal piston stops are of sturdy design. The admissible piston speed depends on the mass fixed to the piston and can be read in the diagram on page 5 of the catalogue sheet.

*) Maximum operating pressure 250 bar Required for punching applications due to the high load caused by the cutting impact. Even with the high-pressure version (500 bar), the pressure must be limited to 250 bar. The advantage of this is the longer service life of the high-pressure seals.

Discover our extensive product range at www.roemheld.de/en!

Hydraulic swing clamps with position monitoring

|

Clamping device, hydraulic

ROEMHELD

Clamping devices, hydraulic

Swing clamps with robust swing mechanism

- top flange type

- with optional integrated pneumatic position monitoring

- double acting

- max. operating pressure 70 bar

Hydraulic swing clamps are used for clamping workpieces where the clamping points must be free for loading and unloading the fixture. This series achieves very high clamping forces even at 70 bar and can be connected directly to the low-pressure hydraulics of machine tools. An additional power unit for the clamping hydraulics is no longer necessary.

With the robust swivel mechanism and the optional position controls, the swing clamps are particularly suitable for:

- Fully automated manufacturing systems with very short cycle times

- Clamping devices with workpiece changeover by handling systems

- Transfer lines

- Testing systems for motors, gears and axles

- Assembly lines

- Special processing machines

With the new integrated pneumatic position control, users save space compared to the previously available position control. The double-acting elements with top flange are offered in four sizes. Because of their compact design, they are partially retractable and achieve very high effective clamping forces of up to 13.3 kN even at 70 bar operating pressure.

The hydraulic swing clamp is a pull cylinder in which part of the total stroke is used as a swing stroke to rotate the piston. Due to the robust swivel mechanism, the angular position of the clamp is maintained even after a slight collision during loading and unloading of the workpiece or during the clamping process. The angular position of the clamping bar is fixed with a cylindrical pin. The FKM wiper on the piston rod can be protected from coarse and hot chips by the optionally available metal wiper. The version with continuous switching rod is intended for the attachment of a pneumatic or an electric position control (accessory).

Discover our extensive product range at www.roemheld.de/en!

- top flange type

- with optional integrated pneumatic position monitoring

- double acting

- max. operating pressure 70 bar

Hydraulic swing clamps are used for clamping workpieces where the clamping points must be free for loading and unloading the fixture. This series achieves very high clamping forces even at 70 bar and can be connected directly to the low-pressure hydraulics of machine tools. An additional power unit for the clamping hydraulics is no longer necessary.

With the robust swivel mechanism and the optional position controls, the swing clamps are particularly suitable for:

- Fully automated manufacturing systems with very short cycle times

- Clamping devices with workpiece changeover by handling systems

- Transfer lines

- Testing systems for motors, gears and axles

- Assembly lines

- Special processing machines

With the new integrated pneumatic position control, users save space compared to the previously available position control. The double-acting elements with top flange are offered in four sizes. Because of their compact design, they are partially retractable and achieve very high effective clamping forces of up to 13.3 kN even at 70 bar operating pressure.

The hydraulic swing clamp is a pull cylinder in which part of the total stroke is used as a swing stroke to rotate the piston. Due to the robust swivel mechanism, the angular position of the clamp is maintained even after a slight collision during loading and unloading of the workpiece or during the clamping process. The angular position of the clamping bar is fixed with a cylindrical pin. The FKM wiper on the piston rod can be protected from coarse and hot chips by the optionally available metal wiper. The version with continuous switching rod is intended for the attachment of a pneumatic or an electric position control (accessory).

Discover our extensive product range at www.roemheld.de/en!

Swing clamps with sturdy swing mechanism

|

Clamping device, hydraulic

ROEMHELD

Clamping devices, hydraulic

Swing clamps with sturdy swing mechanism

- Cartridge type

- position monitoring optional

- double acting

- max. operating pressure 350 bar

Hydraulic swing clamps are used for clamping of workpieces, when it is essential to keep the clamping area free of straps and clamping components for unrestricted workpiece loading and unloading.

This series obtains very high clamping forces already at 120 bar and can directly be connected to the low-pressure hydraulics of the ma-

chine tool. An additional power unit for power workholding is no longer necessary.

With the sturdy swing mechanism and the optional position monitoring these swing clamps are particularly suitable for:

Automatic manufacturing systems with very short cycle times

Clamping fixtures with workpiece loading by handling systems

Transfer lines

Test systems for motors, gears and axes

Assembly lines

Special machine tools

The hydraulic swing clamp is a pull-type cylinder where a part of the total stroke is used to swing the piston.

Due to the sturdy swing mechanism the angle position of the clamping arm remains the same after a slight collision with the workpiece during loading and unloading or during clamping.

The angle position of the clamping arm is fixed with a dowel pin.

The FKM wiper at the piston rod can be protected against coarse and hot swarf by an optionally available metallic wiper.

The version with extended switch rod is provided for mounting of pneumatic or electrical position monitorings (accessory).

Version without bottom cover

Focusing on a short length, the bottom cover had been omitted. The piston contacts the bottom of the cartridge-type hole.

Discover our extensive product range at www.roemheld.de/en!

- Cartridge type

- position monitoring optional

- double acting

- max. operating pressure 350 bar

Hydraulic swing clamps are used for clamping of workpieces, when it is essential to keep the clamping area free of straps and clamping components for unrestricted workpiece loading and unloading.

This series obtains very high clamping forces already at 120 bar and can directly be connected to the low-pressure hydraulics of the ma-

chine tool. An additional power unit for power workholding is no longer necessary.

With the sturdy swing mechanism and the optional position monitoring these swing clamps are particularly suitable for:

Automatic manufacturing systems with very short cycle times

Clamping fixtures with workpiece loading by handling systems

Transfer lines

Test systems for motors, gears and axes

Assembly lines

Special machine tools

The hydraulic swing clamp is a pull-type cylinder where a part of the total stroke is used to swing the piston.

Due to the sturdy swing mechanism the angle position of the clamping arm remains the same after a slight collision with the workpiece during loading and unloading or during clamping.

The angle position of the clamping arm is fixed with a dowel pin.

The FKM wiper at the piston rod can be protected against coarse and hot swarf by an optionally available metallic wiper.

The version with extended switch rod is provided for mounting of pneumatic or electrical position monitorings (accessory).

Version without bottom cover

Focusing on a short length, the bottom cover had been omitted. The piston contacts the bottom of the cartridge-type hole.

Discover our extensive product range at www.roemheld.de/en!

Threaded-Body Work Supports

|

Clamping device, hydraulic

ROEMHELD

Clamping devices, hydraulic

Threaded-Body Work Supports

- 3 function types, with metallic wiper edge,

- optional contact control

- single acting, max. operating pressure 500 bar

Hydraulic work supports are used to provide a self-adjusting rest for workpieces and avoid their vibration and deflection under machining loads.

The threaded-body design allows for space-saving and direct installation into the fixture body. Hydraulic oil supply and venting are made via drilled channels.

In the body of the threaded-body work supports a thin-walled locking bush is integrated, which locks cylindrically around the freely-movable support plunger when pressurising the element with hydraulic oil.

There are three variations of plunger actuation:

- Spring force

- Pneumatically

- Hydraulically and spring force

The correct contact at the workpiece can be controlled with the optional pneumatic contact control. The body with metallic wiper edge protects the subjacent FKM wiper against coarse and hot swarf.

Discover our extensive product range at www.roemheld.de/en!

- 3 function types, with metallic wiper edge,

- optional contact control

- single acting, max. operating pressure 500 bar

Hydraulic work supports are used to provide a self-adjusting rest for workpieces and avoid their vibration and deflection under machining loads.

The threaded-body design allows for space-saving and direct installation into the fixture body. Hydraulic oil supply and venting are made via drilled channels.

In the body of the threaded-body work supports a thin-walled locking bush is integrated, which locks cylindrically around the freely-movable support plunger when pressurising the element with hydraulic oil.

There are three variations of plunger actuation:

- Spring force

- Pneumatically

- Hydraulically and spring force

The correct contact at the workpiece can be controlled with the optional pneumatic contact control. The body with metallic wiper edge protects the subjacent FKM wiper against coarse and hot swarf.

Discover our extensive product range at www.roemheld.de/en!