ROEMHELD

Products

Your solution provider in clamping and handling technology

ROEMHELD

Machine vices

HILMA.MCP

| 8-35 kN | |

| 15-25 kN | |

| 40-125 mm |

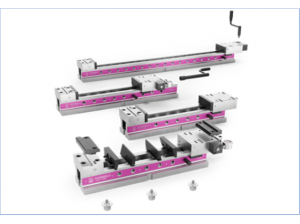

HILMA.MCP

- HILMA.MCP clamping against fixed jaw, mechanically operated, jaw widths: 40, 60, 100 and 125 mm

- HILMA.MCP Z concentric clamping, mechanically or hydraulically operated, jaw widths: 40, 60, 100 and 125 mm

- HILMA.MCP ZB position flexible clamping, mechanically operated, jaw widths: 60, 100 and 125 mm

Application

The workholding systems HILMA.MCP are especially advantageous for 5-axis machining. The compact design allows a good accessibility of the tools to the workpiece. Collision-free tool paths and a 5-sided workpiece machining can be achieved with short standard tools. Due to the good swarf protection, workholding systems HILMA.MCP are particularly suitable for the use in pallet systems. The high force and stability obviate the need for pre-stamping of the workpieces.

Description

Workholding systems of the HILMA.MCP series excel by a very compact design and their patented segment design. Thanks to the adjusting spindle arranged in the upper part of the housing, deformation in the base during clamping is reduced to a minimum. Thus, a high rigidity of the workholding system is obtained. The patented segment design ensures a high degree of precision and stability. The guiding clearance is reduced to nearly zero. All essential components are made of hardened steel. The workholding systems of the HILMA.MCP series are already prepared for the use on zero point clamping systems. For this purpose, there are location threads for retractable nipples at the bottom side of the housing.

Advantages

- Patented segment design

- Clamping without deformation of workpieces by position flexible clamping point

- Clamping system also suitable for concentric clamping

- high zero-point stability

- Compact design

- High precision and accuracy of the manufactured workpieces by high rigidity

- Sturdy design and good swarf protection

- Large jaw openings

- Extensive range of jaws

- Clamping of raw and finished parts without retrofitting

- Easy to maintain

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

- HILMA.MCP clamping against fixed jaw, mechanically operated, jaw widths: 40, 60, 100 and 125 mm

- HILMA.MCP Z concentric clamping, mechanically or hydraulically operated, jaw widths: 40, 60, 100 and 125 mm

- HILMA.MCP ZB position flexible clamping, mechanically operated, jaw widths: 60, 100 and 125 mm

Application

The workholding systems HILMA.MCP are especially advantageous for 5-axis machining. The compact design allows a good accessibility of the tools to the workpiece. Collision-free tool paths and a 5-sided workpiece machining can be achieved with short standard tools. Due to the good swarf protection, workholding systems HILMA.MCP are particularly suitable for the use in pallet systems. The high force and stability obviate the need for pre-stamping of the workpieces.

Description

Workholding systems of the HILMA.MCP series excel by a very compact design and their patented segment design. Thanks to the adjusting spindle arranged in the upper part of the housing, deformation in the base during clamping is reduced to a minimum. Thus, a high rigidity of the workholding system is obtained. The patented segment design ensures a high degree of precision and stability. The guiding clearance is reduced to nearly zero. All essential components are made of hardened steel. The workholding systems of the HILMA.MCP series are already prepared for the use on zero point clamping systems. For this purpose, there are location threads for retractable nipples at the bottom side of the housing.

Advantages

- Patented segment design

- Clamping without deformation of workpieces by position flexible clamping point

- Clamping system also suitable for concentric clamping

- high zero-point stability

- Compact design

- High precision and accuracy of the manufactured workpieces by high rigidity

- Sturdy design and good swarf protection

- Large jaw openings

- Extensive range of jaws

- Clamping of raw and finished parts without retrofitting

- Easy to maintain

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

HILMA.NC

|

Machine vice

ROEMHELD

Machine vices

HILMA.NC machine vice

- jaw widths 100, 125 and 160 mm

The modular system of the HILMA.NC series is preferably used on vertical machining centres. Depending on the machining strategy and degree of automation, the clamping force can be applied manually by means of a crank handle (HILMA.NC) or hydraulically by means of a power unit (HILMA.NCH).

Special features of the HILMA.NC machine vice family:

- adapted: three jaw widths and variable base lengths

- modular: extensive range of jaws and accessories

- fixed: optimal possibilities for fixation

- safe: precise and constant clamping force

- clean: easy cleaning

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

- jaw widths 100, 125 and 160 mm

The modular system of the HILMA.NC series is preferably used on vertical machining centres. Depending on the machining strategy and degree of automation, the clamping force can be applied manually by means of a crank handle (HILMA.NC) or hydraulically by means of a power unit (HILMA.NCH).

Special features of the HILMA.NC machine vice family:

- adapted: three jaw widths and variable base lengths

- modular: extensive range of jaws and accessories

- fixed: optimal possibilities for fixation

- safe: precise and constant clamping force

- clean: easy cleaning

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

HILMA.SCS

|

Workholding System

ROEMHELD

Machine vices

WS 5.4600

| 80 und 120 mm | |

| 21 bis 40 kN |

HILMA.SCS Workholding System

- clamping against the fixed jaw

- mechanically or hydraulically operated

- jaw widths 80 and 120 mm

The clamping systems of the series HILMA.SCS are particularly suitable for use on 5-axis machining centres. Thanks to the compact design, the risk of collisions of the machine spindle with the clamping system is minimised. An improved accessibility to small workpieces is achieved by moving the fixed jaw.

The combined use of clamping systems of the series HILMA.SCS and the rapid change block Quintus provides additional benefits: On the one hand the important distance to the machine table is created, on the other hand setups can be transferred from internal to external and thus the machine running time can be prolonged. This is made by creating a defined interface for the quick change to other clamping systems, for example on three-jaw chucks.

The extensive range of jaws allows the use of the HILMA.SCS clamping systems for a multitude of machining operations. The clamping systems of the series HILMA.SCS is available as a mechanical or hydraulic system, depending on the requirements.

Special benefits

- collision-free tool paths

- good protection against swarf by covered lead screw and guideway

- easy clamping with torque wrench or hydraulically

- flexible applications, extensive accessories and range of clamping jaws

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

- clamping against the fixed jaw

- mechanically or hydraulically operated

- jaw widths 80 and 120 mm

The clamping systems of the series HILMA.SCS are particularly suitable for use on 5-axis machining centres. Thanks to the compact design, the risk of collisions of the machine spindle with the clamping system is minimised. An improved accessibility to small workpieces is achieved by moving the fixed jaw.

The combined use of clamping systems of the series HILMA.SCS and the rapid change block Quintus provides additional benefits: On the one hand the important distance to the machine table is created, on the other hand setups can be transferred from internal to external and thus the machine running time can be prolonged. This is made by creating a defined interface for the quick change to other clamping systems, for example on three-jaw chucks.

The extensive range of jaws allows the use of the HILMA.SCS clamping systems for a multitude of machining operations. The clamping systems of the series HILMA.SCS is available as a mechanical or hydraulic system, depending on the requirements.

Special benefits

- collision-free tool paths

- good protection against swarf by covered lead screw and guideway

- easy clamping with torque wrench or hydraulically

- flexible applications, extensive accessories and range of clamping jaws

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

HILMA.UC 125

|

Machine vice

ROEMHELD

Machine vices

| concentric | |

| mechanical | |

| 52 kN | |

| 0-200 mm | |

| 350 mm |

HILMA.UC 125 machine vice

Modular, flexible, precise, jaw width 125

The HILMA.UC125 universal clamping system is suitable for almost unlimited clamping tasks. Small workpieces as well as large plates can be clamped and machined with high degrees of freedom. Even when production requirements change, there is no need to invest in new clamping devices. The HILMA.UC universal clamping system can be adapted to different workpiece geometries in just a few steps.

Special features of the HILMA.UC 125 machine vice family:

- universal: for 3, 4 or 5-axis machining centres as well as turning and milling machines

- precise clamping: center clamping with pull-down effect

- modular: versatile accessories

- flexible: clamps small workpieces up tp large plates

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!

Modular, flexible, precise, jaw width 125

The HILMA.UC125 universal clamping system is suitable for almost unlimited clamping tasks. Small workpieces as well as large plates can be clamped and machined with high degrees of freedom. Even when production requirements change, there is no need to invest in new clamping devices. The HILMA.UC universal clamping system can be adapted to different workpiece geometries in just a few steps.

Special features of the HILMA.UC 125 machine vice family:

- universal: for 3, 4 or 5-axis machining centres as well as turning and milling machines

- precise clamping: center clamping with pull-down effect

- modular: versatile accessories

- flexible: clamps small workpieces up tp large plates

Discover our extensive product range at www.roemheld.de/en and www.stark-roemheld.com/en!