ROEMHELD

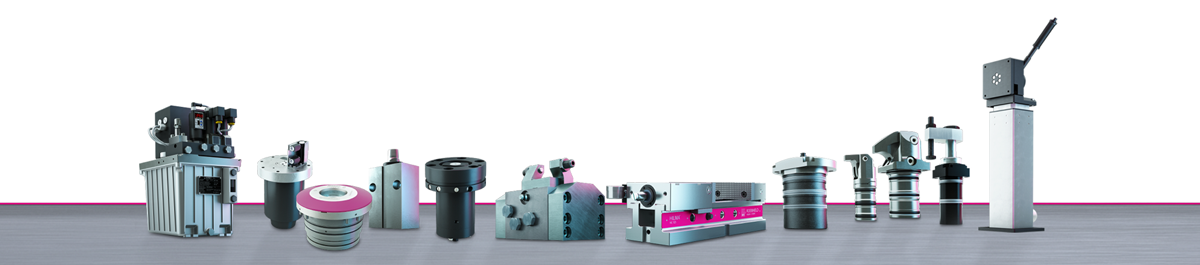

Products

Your solution provider in clamping and handling technology

Parts and components

Hydraulic and pneumatic components

Bore clamps, Eccentric

|

Hydraulic component, control and accessory

ROEMHELD

Hydraulic components, controls and accessories

| 8-12 mm | |

| 120 bar |

Bore clamps Eccentric

- Pneumatic seat check and clamping monitoring

- bore holes Ø 8 – 12 mm

- double acting, max. operating pressure 80 and 120 bar

The hydraulically-operated bore clamp is particularly suitable for clamping in workpieces with smooth bore holes in the support surface ranging from 8 to 12 mm in diameter.

The workpiece is placed directly onto the hardened supports of the bore clamp and is not deformed during clamping. Since clamping is effected within the bore, the remaining surfaces are free for machining on 5 sides.

The double-acting hydraulic cylinder operates a tie bolt that is eccentrically arranged at the edge of the housing in which the clamping bolt is safely engaged.

This conical clamping bolt expands the hardened clamping bushing so that its points penetrate the bore surface in the workpiece with a positive fit (see “Clamping principle”).

Clamping bolt and clamping bushing can be exchanged very quickly after loosening the workpiece support. The bore clamp can remain on the fixture and no hydraulic oil escapes.

All functions can be monitored pneumatically. The use of the connection for positive air pressure protection prevents liquids and swarf from entering the clamping bushing.

Discover our extensive product range at www.roemheld.de/en!

- Pneumatic seat check and clamping monitoring

- bore holes Ø 8 – 12 mm

- double acting, max. operating pressure 80 and 120 bar

The hydraulically-operated bore clamp is particularly suitable for clamping in workpieces with smooth bore holes in the support surface ranging from 8 to 12 mm in diameter.

The workpiece is placed directly onto the hardened supports of the bore clamp and is not deformed during clamping. Since clamping is effected within the bore, the remaining surfaces are free for machining on 5 sides.

The double-acting hydraulic cylinder operates a tie bolt that is eccentrically arranged at the edge of the housing in which the clamping bolt is safely engaged.

This conical clamping bolt expands the hardened clamping bushing so that its points penetrate the bore surface in the workpiece with a positive fit (see “Clamping principle”).

Clamping bolt and clamping bushing can be exchanged very quickly after loosening the workpiece support. The bore clamp can remain on the fixture and no hydraulic oil escapes.

All functions can be monitored pneumatically. The use of the connection for positive air pressure protection prevents liquids and swarf from entering the clamping bushing.

Discover our extensive product range at www.roemheld.de/en!

Power Units in Modular Design

|

Hydraulic pump and distributor

ROEMHELD

Hydraulic pumps and distributors

| 30 - 500 bar | |

| 0,9 - 12 l/min | |

| 11 l, 27 l, 40 l, 63 l |

Power Units in Modular Design

- Operating pressure 30 to 500 bar

- flow rate 0.9 to 12 l/min

- reservoir sizes 11 l, 27 l, 40 l, 63 l

Application

For the operation of hydraulic clamping fixtures and other handling and clamping systems on machine tools.

Description

The power units of this series consist of individual modules that are selected depending on the application and are assembled on the basis of a type code to a power unit ready for use.

Modules

- power unit (reservoir, pump, motor)

- connecting block basic functions

- valve block with up to 4 control circuits

- electronics

Characteristics

- for single and double-acting cylinders

- continuously adjustable operating pressure

- expandable to up to 8 pressure circuits

- constant flow rate

- wide range of valves

- wide range of hydraulic functions

- energy-saving mode S3 (intermittent mode) or S6 (unpressurised cycle)

- supplied ready for connection

Equipment - Standard

- connecting block with pressure relief valve

- pressure filter 10 μm

- oil level gauge

- stick thermometer

- design without piping

Equipment - Options

- electronic system pressure switch (with teach-in function)

- system pressure switch or machine tool interlock, mechanical or electronic

- electrical oil level control

- electrical temperature control

- return filter

- electrical filter control

- electric control

- terminal box

- foot switch or manual switch

- key switch

Discover our extensive product range at www.roemheld.de/en!

- Operating pressure 30 to 500 bar

- flow rate 0.9 to 12 l/min

- reservoir sizes 11 l, 27 l, 40 l, 63 l

Application

For the operation of hydraulic clamping fixtures and other handling and clamping systems on machine tools.

Description

The power units of this series consist of individual modules that are selected depending on the application and are assembled on the basis of a type code to a power unit ready for use.

Modules

- power unit (reservoir, pump, motor)

- connecting block basic functions

- valve block with up to 4 control circuits

- electronics

Characteristics

- for single and double-acting cylinders

- continuously adjustable operating pressure

- expandable to up to 8 pressure circuits

- constant flow rate

- wide range of valves

- wide range of hydraulic functions

- energy-saving mode S3 (intermittent mode) or S6 (unpressurised cycle)

- supplied ready for connection

Equipment - Standard

- connecting block with pressure relief valve

- pressure filter 10 μm

- oil level gauge

- stick thermometer

- design without piping

Equipment - Options

- electronic system pressure switch (with teach-in function)

- system pressure switch or machine tool interlock, mechanical or electronic

- electrical oil level control

- electrical temperature control

- return filter

- electrical filter control

- electric control

- terminal box

- foot switch or manual switch

- key switch

Discover our extensive product range at www.roemheld.de/en!

Pneumatic swing clamps

|

Pneumatic component, control and accessory

ROEMHELD

Pneumatic components, controls and accessories

| 140 - 1400 N | |

| 8 - 25 mm | |

| 20 - 63 mm | |

| 7 - 18 mm | |

| 7 bar |

Pneumatic swing clamps are used for applications which require only low clamping forces. The installed magnetic piston allows monitoring of clamping and unclamping position. When pressurising the element, the clamping arm swings and lowers by 90° to the clamping position and then lowers to the clamping point. The position monitoring gives the required information regarding the position of the piston, but not regarding the position of the clamping arm. Monitoring is made by electronic sensors which detect the magnetic field of the magnetic piston. The switching points can be continuously adjusted by displacement of the magnetic sensors.

Discover our extensive product range at www.roemheld.de/en!

Discover our extensive product range at www.roemheld.de/en!