Samsys

Products

Samsys GmbH

Gripping tools and automatic fixtures

Gecko Gripper from OnRobot

Gecko Gripper

The Gecko Gripper (SP) enables the use of the innovative Gecko adhesive gripper technology in applications with a small surface area. Such areas which could not be automated so far. The gecko-inspired adhesive technology offers precise, track-free gripping. Even with porous workpieces this technology works. For example printed circuit boards or glossy surfaces. Cleaning is not necessary. The three different Gecko Single Pad Grippers (SP1, SP3 and SP5) are named after their payload in kilograms. Of course, the Gecko grippers can be used with leading lightweight robots and cobots. The compact single-pad design allows easy access to the workpiece, even in tight spaces. Since no electronics or air supply is required, the Gecko SP is a cost-effective plug-and-play solution.

The Gecko gripper leaves no marks on glass. This eliminates the need for manual cleaning. This means a higher RoI and lower operating costs.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Functionality

Due to the simple connection of the grippers and the operation and programming via the dedicated URCap (only applies to Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick-change system Quick Changer and Dual Quick Changer.

Features of the Gecko gripper

The Gecko gripper SP enables automation even with flat, shiny or porous workpieces. Gripping of the workpieces is completely free of traces and without electricity or air supply. The Gecko SP is available in three sizes, SP1, SP3 and SP5. The designation of the Gecko grippers is based on the payload of the gripper in kilograms. This allows them to grip different flat, smooth, shiny or perforated surfaces. Since the technology leaves no marks even on high-gloss surfaces, there is no need for a cleaning step in the manufacturing processes. This saves time and increases production output. The Gecko SP can grip even porous workpieces such as printed circuit boards, aluminium mesh or head gaskets.

ProFeeder Flex

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

The ProFeeder Flex robot trolley from EasyRobotics opens up new ways of account-friendly and mobile machine feeding in whole different areas.

It is placed on a machine together with a robot from Universal Robots. The docking module facilitates easy alignment and positioning. Its primary task is machine loading and unloading. However, there are of course no limits to its application and it can also be used for handling work.

Application area

In modern production it is often necessary to move semi-finished goods from machine to machine for further processing. The ProFeeder Flex is mobile in your production with its rollers and positions itself with a docking station to another machine in shortest time.

The ProFeeder Flex is available in 3 different versions:

ProFeeder Flex Base: The robot is mounted on a pedestal. There are no additional storage tables in this variant, only a storage area in which the robot?s controller is placed.

ProFeeder Flex One: Instead of the storage surface, a storage table is mounted. Workpieces can be placed on it, but also KTS boxes.

Profeeder Flex Three: The number of deposit tables has been increased to three. This increases the unmanned processing time as well as the space for workpieces.

The ProFeeder Flex robot trolley from EasyRobotics opens up new avenues of account-friendly and mobile machine loading in whole different areas.

In addition, you can increase your productivity by using OnRobot grippers. Thanks to the newly developed Quick Changer module, grippers can be changed in no time at all.

In addition, OnRobot grippers can be easily connected and programmed via the URCap.

The ProFeeder Flex was developed with modernity and maximum mobility in mind. The integrated wheels and handles make it easy to move and set up.

Whether for loading measuring machines or pick-and-place applications, we modernize your production with the compact robot unit.

Vacuum gripper VGP20 from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Vacuum gripper VGP20

Due to its compact design and nevertheless high number of suction cups, the VGP20 from OnRobot is the most powerful vacuum gripper worldwide. With a payload of 20kg, its field of application is ideally the palletizing of boxes, cardboard boxes and workpieces. The nature of the surface, especially in the case of cardboard packaging, does not play a major role here. Therefore it is perfect for handling porous objects such as cartons made of thinner, less expensive cardboard or recycled materials.

Like any vacuum gripper from OnRobot, the suction channels of the VGP20 can be controlled individually, allowing several objects to be moved and set down at the same time. By using one of the integrated options, the gripper?s airflow can be continuously monitored. If the vacuum is lost, the robot stops immediately and a pop-up window in the gripper software draws attention to the incident.

Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

The vacuum gripper is equipped with double gripper functionality, a tool changer and various common suction cup attachments.

In addition, there are many third-party suction cup attachments on the market to fit any application.

Ideal for packaging and palletizing, machine loading or placement.

Functionality

The grippers are ready for use in the shortest possible time by using the URCap specifically made for the OnRobot grippers. In addition, the connection time is reduced by the OnRobot Quick Changer and Dual Quick Changer system.

Features of the VGC10

Due to its compact design and nevertheless high number of suction cups, the VGP20 from OnRobot is the most powerful vacuum gripper worldwide. The payload of 20kg helps to move objects with porous or uneven surfaces. It does not require an external air pump or compressed air at all. With adaptable suction cup mounts, there are no limits to the gripper.

2 Finger Gripper RG2 from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

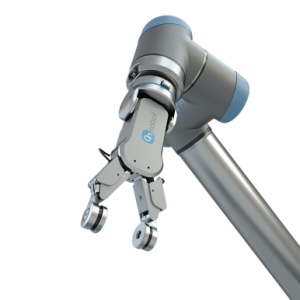

2 Finger Gripper RG2

The two-finger gripper RG2 is a robot arm gripper with a payload of 2 kg. It is a collaborative gripper that is extremely flexible thanks to the integrated Quick Changer and a stroke of up to 110 mm. It offers intelligence, fast deployment, easy customization, and simple and intuitive programming. The outstanding software features of this system solution from OnRobot significantly reduce development and manufacturing times.

The RG2 gripper is a tool for a wide range of applications. Adjustable fingertips provide great flexibility when gripping. This allows customers to use one tool for different parts of the production process. The result is a maximization of robot utilization.

The RG2 works seamlessly with OnRobot?s Dual Quick Changer and any other OnRobot gripper. This allows you to get the most out of your robot. Protective covers for the two-finger gripper RG2 are included in the standard scope of delivery. Another feature is the TÜV certification of the RG2.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Functionality

Due to the simple connection of the grippers and the operation and programming via the own URCap (applies only to robots from Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick change system Quick Changer and Dual Quick Changer.

Features of the RG2

A combination of the RG2 two-finger gripper with the Dual Quick Changer module is possible. The Dual Quick Changer works on the same principle as the Quick Changer module. However, the Dual Quick Changer was developed to allow the simultaneous use of two gripper tools. An example would be to install an RG2 gripper and an RG6 gripper in parallel.

OnRobot?s unique robot gripper tool helps you get the most out of your robots. The Dual Quick Changer makes it possible to handle several workpieces simultaneously. Thus a reduction of the production time is achieved. In general, the Dual Quick Changer can increase production efficiency by about 50%.

2 Finger Gripper RG2-FT from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Robot gripper RG2-FT

The Intelligent Robot gripper RG2-FT is a modern gripper with additional sense of touch and intelligence. It has an integrated force/torque and proximity sensor for extremely precise automation. This enables real collaboration with human users and supports them like a helping hand. Insertion is faster and more precise. For example, this gripper can easily insert pins, which would be difficult for humans. Due to the advanced sensor technology, the gripper allows the robot to feel during assembly when a part is correctly assembled. The RG2-FT Robot gripper offers high productivity and rapid deployment, saving technicians many hours of man-hours during integration.

It´s the world?s first robot gripper with integrated force/torque and proximity sensors that can see and feel objects to ensure extremely safe handling

The Robot gripper RG2-FT can accurately detect the position of objects. It detects the risk of slipping before it happens, thus improving production quality through accurate touching.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Functionality

Due to the simple connection of the grippers and the operation and programming via the dedicated URCap (only applies to Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick change system Quick Changer and Dual Quick Changer.

Features of the RG2-FT

The RG2-FT Robot gripper is a unique version of the RG series with integrated force/torque sensors and a proximity sensor at the finger tips. This allows the position of objects to be detected precisely. It is an advanced gripper with advanced perception and intelligence. It´s capable of controlling the robot and itself to achieve exactly what the user has in mind. Even if precise parameters cannot be programmed in advance.

This enables true collaboration with human users, as it supports the user like a helping hand and ensures precise handling hour after hour.

2 Finger Gripper RG6 from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

2 Finger Gripper RG

The 2 Finger Gripper RG6 is a robot arm gripper with a payload of 6 kg. It is a collaborative gripper that is extremely flexible thanks to the integrated Quick Changer and a stroke of up to 160 mm. It offers intelligence, fast deployment, easy customization, and simple and intuitive programming. The outstanding software features of this system solution from OnRobot significantly reduce development and manufacturing times.

The RG6 gripper is a tool for a wide range of applications. Adjustable fingertips provide great flexibility when gripping. This allows customers to use one tool for different parts of the production process. The result is a maximization of robot utilization.

The RG6 works seamlessly with OnRobot?s Dual Quick Changer and any other OnRobot gripper. This allows you to get the most out of your robot. Protective covers for the two-finger gripper RG6 are included in the standard scope of delivery. Another feature is the TÜV certification of the RG6.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Functionality

Due to the simple connection of the grippers and the operation and programming via the own URCap (applies only to robots from Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick change system Quick Changer and Dual Quick Changer.

Features of the RG6

A combination of the 2 finger gripper RG6 with the Dual Quick Changer module is possible. The Dual Quick Changer works on the same principle as the Quick Changer module. However, the Dual Quick Changer was developed to allow the simultaneous use of two gripper tools. An example would be to install an RG2 gripper and an RG6 gripper in parallel.

OnRobot?s unique robot gripper tool helps you get the most out of your robots. The Dual Quick Changer makes it possible to handle several workpieces simultaneously. Thus a reduction of the production time is achieved. In general, the Dual Quick Changer can increase production efficiency by about 50%.

3 finger gripper 3FG15 from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

3 finger gripper 3FG15

The 3FG15 3 finger gripper is ideal for gripping a wide variety of cylindrical objects. For example, for the feeding of CNC lathes. Due to the design of the gripper, workpieces are automatically centred. This ensures quick readiness for use as well as a strong, stable grip and precise placement. With a payload of up to 15 kg, the 3FG15 competes with larger, bulkier and much less flexible finger grippers. Like all OnRobot grippers, the 3FG15 can be seamlessly integrated into the robot of your choice.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Due to its flexibility and large stroke, the 3 finger gripper is suitable for various applications. For example for the CNC ? machine loading . Another possibility of application would be assembly. It is also ideal for packaging and palletising.

Functionality

Due to the simple connection of the grippers and the operation and programming via the dedicated URCap (only applies to Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick change system Quick Changer and Dual Quick Changer.

Features of the 3FG15

The 3FG15 3 finger gripper has an impressive maximum stroke of 150 mm and a slim design that makes it easy to handle a wide range of processes. It is ideal for gripping a wide variety of cylindrical objects with a width of 20 mm to 150 mm, for example when feeding CNC lathes, in insert applications and even for palletizing. The 3FG15 provides a strong, stable grip for both positive (inside the object) and non-positive (outside) gripping, increasing the flexibility of your implementation. Due to the design of the gripper, workpieces are automatically centred. This ensures a strong, stable grip and precise placement in the clamping head. With a payload of up to 15 kg and a gripping force of 10 N to 240 N, the 3FG15 competes with larger, bulkier and much less flexible finger grippers.

Double Gripper Dual Quick Changer from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Double Gripper Dual Quick Changer

Do you want to use the OnRobot grippers as double grippers? The Dual Quick Changer double gripper system allows the use of different OnRobot gripping tools in one pass. With this innovative solution, you can use two RG2 grippers or one RG6 gripper with a VG10 ? it?s up to you. Switch quickly and seamlessly between our tools with the Dual Quick Changer to maximize the utilization of your robots. With the Dual Quick Changer, throughput times can be accelerated and thus the productivity of your plant increased.

Not only suitable for OnRobot products. The DUAL Quick Changer can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example are existing tools, which can also be equipped with the OnRobot quick-change system.

The Dual Quick Changer is the alternative to the Quick Changer. This makes it easy to install two tools on one robot arm.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Functionality

A simple push on the release button and the tool can be removed. The new tool is just as easily reinserted and pressed into the quick-change system until the lock engages. Thus, the change from one tool to the next takes only a few moments.

Features of the Dual Quick Changer

The Dual Quick Changer double gripper quick change system offers the same flexibility and fast tool change as the normal Quick Changer. The only difference is that you can now equip your robot with two gripper tools at the same time. If you equip your robot arm with two end effectors, two tools can be used in one pass. This allows an increase in productivity of 50% or more. The Dual Quick Changer has a low height and low weight and is suitable for all common robot brands. So you can use our tools with your existing robots and achieve maximum efficiency.

ER Work

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

The mobile robot ER Work from EasyRobotics is a compact robot station which can be used for handling work or CNC assembly.

The ER Work is most often used in combination with the ProFeeder Compact. Here the ProFeeder Compact serves as a kind of parts store. In this case the ER Work loads and unloads the machine. Of course, the ER Work can also do its work alone in front of a CNC machine.

Field of application

In modern productions, workpieces are often transported from machine to machine for further processing. The ER Work with its rollers is mobile in your production and can be connected to another machine in no time with an optional docking station.

In this way, an ER Work can accompany an entire production cycle and take over part handling.

With a UR5e or UR16e from Universal Robots, the ER Work is therefore ideal for loading and unloading machines. However, there are no limits to the application. It can also be used on conveyor belts or as an assembly aid.

The mobile robot ER Work from EasyRobotics is a compact robot station that can be used for handling work or CNC assembly.

With the use of OnRobot grippers you can also increase your productivity.

With the newly developed Quick Changer module from OnRobot, grippers can be changed in no time at all.

Grippers from OnRobot can be used in many areas. Workpieces of almost any shape can be processed with a three-finger gripper from OnRobot. That this increases productivity and is time-efficient, we do not need to explain further at this point.

The ER Work was developed with safety and maximum mobility in mind. The integrated rollers and handles make it easy to move and set up the ER Work.

Whether for the loading of measuring machines or pick-and-place applications, with the compact robot unit we make your production easier.

Gecko Gripper from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Gecko Gripper

The Gecko Gripper (SP) enables the use of the innovative Gecko adhesive gripper technology in applications with a small surface area. Such areas which could not be automated so far. The gecko-inspired adhesive technology offers precise, track-free gripping. Even with porous workpieces this technology works. For example printed circuit boards or glossy surfaces. Cleaning is not necessary. The three different Gecko Single Pad Grippers (SP1, SP3 and SP5) are named after their payload in kilograms. Of course, the Gecko grippers can be used with leading lightweight robots and cobots. The compact single-pad design allows easy access to the workpiece, even in tight spaces. Since no electronics or air supply is required, the Gecko SP is a cost-effective plug-and-play solution.

The Gecko gripper leaves no marks on glass. This eliminates the need for manual cleaning. This means a higher RoI and lower operating costs.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Functionality

Due to the simple connection of the grippers and the operation and programming via the dedicated URCap (only applies to Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick-change system Quick Changer and Dual Quick Changer.

Features of the Gecko gripper

The Gecko gripper SP enables automation even with flat, shiny or porous workpieces. Gripping of the workpieces is completely free of traces and without electricity or air supply. The Gecko SP is available in three sizes, SP1, SP3 and SP5. The designation of the Gecko grippers is based on the payload of the gripper in kilograms. This allows them to grip different flat, smooth, shiny or perforated surfaces. Since the technology leaves no marks even on high-gloss surfaces, there is no need for a cleaning step in the manufacturing processes. This saves time and increases production output. The Gecko SP can grip even porous workpieces such as printed circuit boards, aluminium mesh or head gaskets.

Magnetic gripper MG10 from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Magnetic gripper MG10

OnRobot?s MG10 is a versatile magnetic gripper for material handling, assembly and machine tending in manufacturing. Through OnRobot?s unified system solution, the MG10 is compatible with all major robot brands. It offers unique, customizable force and grip detection features that give users unprecedented control. Hereby, the magnetic gripper does not require any external compressed air supply, but is plug-and-play usable via the URCap.

Due to its integrated intelligence, the gripping force can be easily regulated. This also makes it possible to pick up workpieces one on top of the other without moving the other parts. In addition, to ensure safe collaborative operation, the gripper holds the workpiece even in the event of a power failure or emergency stop.

Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Thanks to the easily configurable magnetic force, the OnRobot MG10 can adjust the force even in difficult applications, such as single stacking of metal sheets. An integrated proximity sensor detects whether the part has been picked up or not. Multiple magnet configurations support applications where reliable handling of large or heavy workpieces is required.

Furthermore the cost-effective MG10 requires no external air supply or wiring, so it can be installed quickly and easily at no additional cost. Like all straightforward electric grippers in the OnRobot family, the MG10 uses OnRobot?s Quick Changer and intuitive programming for fast setup.

OnRobot?s MG10 is a versatile magnetic gripper for material handling, assembly and machine tending in manufacturing. Unlike vacuum grippers, OnRobot?s magnetic gripper leaves no marks and can handle perforated, abrasive or dusty workpieces. In press feeding and bending applications, the MG10 can handle parts throughout the process, even if the part changes shape.

Parallel gripper 2FG7 from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

2 Finger Gripper 2FG7

The 2FG7 2 Finger Parallel Gripper is ideal for gripping in confined environments as well as challenging objects, whether inside or outside grip. This easy-to-program, collaborative parallel gripper is equipped with everything you need for rapid deployment in the most diverse work environments. With a maximum payload of 11 kg, an external gripper width of up to 73 mm and a gripping force of 20 N to 140 N, the 2FG7 is versatile even for heavy and bulky workpieces.

Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Due to its flexibility and the relatively large gripping force, the 2 finger gripper is suitable for various applications. Furthermore it can be used for the assembly as well as the area of packaging and palletizing.

Functionality

Due to the simple connection of the grippers and the operation and programming via the dedicated URCap (only applies to Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick change system Quick Changer and Dual Quick Changer.

Features of the 2FG7

The 2FG7 2 Finger Parallel Gripper is ideal for gripping in confined environments as well as challenging objects, whether inside or outside grip.

It has an impressive maximum stroke of 73 mm and a slim design. This allows it to handle a wide variety of processes with ease. With its powerful grip of 20 to 140 N and small footprint, the 2FG7 is the perfect gripper for use in space-constrained work environments. In addition it is perfect for applications with little freedom of movement. Even for demanding workpieces.

The 2FG7 offers a strong, stable grip for both internal and external gripping of the workpiece. Therefore there are only few limits to the possibilities. With a payload of up to 11 kg and a gripping force of 20 N to 140 N, the 2FG7 easily competes with larger and bulkier finger grippers.

ProFeeder

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Series size: The ProFeeder is perfectly suited for automated small and medium series.

Quick changeover: Thanks to the simple carriage changing system, downtimes are significantly reduced and productivity is increased at the same time.

ER+ : A special palletizing software simplifies the installation of the application. Only the dimensions of the workpiece and a quick calibration of the deposit are necessary, then the robot knows where the palletizing level is located and which paths it must travel. Time-saving and stress-free!

Mobility: The robotic cell can be moved from machine to machine either with heavy-duty wheels or with a pallet truck.

Collaborative robots: By using the latest generation of Universal Robots robots, working with the robot has never been safer or more effective. Thanks to the newly installed force moment sensors in the joints, the robot detects even the smallest collisions and stops to prevent damage

ProFeeder Compact

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

The ProFeeder Compact from EasyRobotics is a robust robotic cell with compact dimensions that can be easily moved in your production.

The ProFeeder Compact is placed separately in front of the machine to be operated. Then an ER Work or an ER Pedestal is positioned in front of the machine. The robot is located on the ER Work / ER Pedestal. The robot now takes workpieces from the ProFeeder Compact and loads and unloads the machine. It then loads the workpieces back into the ProFeeder Compact.

This results in advantages for you, such as more space in your production, quick adaptability for different workpieces and a mobile robot cell.

Thanks to the simple design of the drawers of the ProFeeder Compact, workpieces of various sizes and lengths can be processed without major changeover work.

Structure

The ProFeeder Compact from EasyRobotics is a robust robotic cell with compact dimensions that can be moved in your production.

The cell is available in 2 different versions. A distinction is made between the locking types of the drawers. On the one hand, the cell locks the drawers using compressed air or a mechanical system. The locking is necessary to protect the operator and to ensure a smooth running of the program.

The ProFeeder Compact is equipped with 6 drawers as standard.

On the surface of the ProFeeder Compact there are several ways to mount the robot. Due to the various positioning possibilities of the robot, there are almost no limits to its movement cycle.

Optional for the cell are GD heavy duty wheels and a docking station. This makes the ProFeeder Compact mobile and allows it to be connected to different machines in a very short time.

Field of application

The ProFeeder Compact, in combination with the ER Work, can be used in almost all areas of production.

It can be positioned on CNC machines or even on simple conveyor belts.

The latest technology built into the E-series of Universal Robots opens up completely new areas of application. Polishing, grinding and measuring are just a few of the countless possibilities for integrating the robotic cell into your production.

ProFeeder Light

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

With a fixed storage tray, the ProFeeder Light palletizing robot from EasyRobotics is ideally suited for automated processes of small series.

A cost-effective application that sets new standards in precision machining when combined with a robot from Universal Robots. Equipped with special software and the help of UR+ Caps, set-up times as well as machining times can be greatly reduced. In addition, employees can concentrate more on more important activities and increase productivity.

Structure

The ProFeeder Light consists of a robust cell. A storage tray is built onto the surface of the cell. This makes it ideal for processes with small quantities or frequently changing workpieces.

Thanks to the latest generation of Universal Robots robots (e-series) and the force torque sensor built into it, the robotic cell is safer than ever. The robot stops at the slightest deviation of its programming path, e.g. due to a collision or a programming error.

Optionally equipped with heavy-duty wheels, the cell can be connected to various machines in a mobile manner.

The robot is mounted on a base which can be fixed on three different sides. The base can also be rotated. Thus the robot either sits on a straight surface or is angled at 45°.

With a firmly fixed storage tray, the ProFeeder Light palletizing robot is ideally suited for automated processes in small series.

If work is required in the area of machine feeding, EasyRobotics? ER+ software makes programming easier. It is specially designed for easy programming of palletizing functions. The surface is calibrated and the dimensions of the workpiece are entered with a tool that is attached instead of the gripper. Workpieces can then be changed within a few minutes and changeover times are greatly reduced.

The ER+ software as well as the software of OnRobot or Robotiq grippers is installed via a URCap. Simply connect the stick supplied to the UR robot. Then start working directly with the accessories.

ProFeeder Table

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

The handling robot ProFeeder Table from EasyRobotics is a perfect assistant for processes in the field of grinding, polishing and deburring.

A cost-effective application that sets new standards in precision machining when combined with a robot from Universal Robots. Equipped with special software and the help of UR+ Caps, set-up times as well as processing times can be greatly reduced. In addition, employees can concentrate more on more important activities and increase productivity.

Structure

The ProFeeder Table simplifies your entry into the world of robot automation. The cell is optionally equipped with a Universal Robots robot of the latest generation. This makes programming easier and protects the operator with its collaborative features. This makes it ideal for the first steps with a robot application.

Optionally equipped with heavy-duty wheels, the cell can be connected to various machines on the move.

The robot is mounted on a base which can be fixed on three different sides. The base can also be rotated. Thus the robot either sits on a straight surface or is angled at 45°.

Application areas

The handling robot ProFeeder Table from EasyRobotics is a perfect assistant for processes in the field of grinding, polishing and deburring.

Different grippers from OnRobot make it possible to use the cell in various applications. With a vacuum gripper, for example, handling work in the area of packing can also be realized.

If work is required in the area of machine assembly, the ER+ software from EasyRobotics makes programming easier. It is specially designed for easy programming of palletizing functions. The surface is calibrated and the dimensions of the workpiece are entered with a tool that is attached instead of the gripper. Workpieces can then be changed within a few minutes and changeover times are greatly reduced.

The ER+ software as well as the software of OnRobot or Robotiq grippers is installed via a URCap. Simply connect the stick supplied to the UR robot. After that you can directly stark working with the equipment.

ProFeeder X

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

The automatic drawer system ProFeeder X from EasyRobotics with its up to 10 drawers is perfectly suited for productions from small to large series.

It shines not only because of its performance thanks to the included software, but also because of its changeover times.

The software, which has been specially created for the ProFeeder X, makes it easier to write the robot programs in the palletizing area. This reduces tiresome programming times and increases productivity at the same time.

Structure

The automatic drawer system ProFeeder X from EasyRobotics with its up to 10 drawers is perfectly suited for productions from small to large series.

With its compact dimensions of 890 x 970 x 1008 mm, the cell can be positioned on almost any machine.

Whether 10, 5 or 2 drawers, the ProFeeder X can be adapted to any workpiece in no time at all. Several hole patterns are predrilled on the surface of the ProFeeder X, on which the robot can be placed by Universal Robots or Nachi, for example. This allows the robot its ultimate flexibility.

2 variants are available for the locking system. On the one hand the drawers can be locked by compressed air (Air-Lock), on the other hand a mechanical locking (Mech-Lock) is possible. The locking of the drawers guarantees protection for the operator not to interfere with running processes and at the same time to maintain productivity.

Functionality

By pressing the release button, the operator confirms that he is opening and loading a drawer to the operator side. If the robot is not working on the drawer at that time, the lock (Air-Lock) opens and the drawer is open. The drawer is now filled with workpieces by the operator. He then closes the drawer again and presses the release button again. This signals to the robot that it can process the drawer.

The robot now moves to the drawer and pulls it out independently. Using a gripper from OnRobot or Robotiq, for example, it now grips a raw part. Afterwards the robot clamps it in the machine after removing the finished part.

When the processing of the drawer is finished, the operator has the release to unlock and reload the drawer.

An optional automatic door is available as a retrofit for almost any of your CNC machines. It is fitted to the door to prevent the robot from having to push the door open by itself. This saves valuable seconds and again increases the productivity of the cell.

Samsys EasyPalletizer

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

The EasyPalletizer is a mobile palletizing robot that is easy to program and operate. It can be extended by any robot arm. The EasyPalletizer is available in 3 versions depending on the height of the load:

with lift module

with fixed base (height 855 mm)

without base

It consists of a robot console the size of a Euro pallet, which contains a compartment for the robot control unit, cables and a lifting module or base. The EasyPalletizer is of robust construction and has a total weight of 300 kg (without robot and without lift module).

Each side of the EasyPalletizer is equipped with a docking station that checks the placement of the pallet using 4 pressure sensors each. Once all pallets have been placed correctly, palletizing begins.

The EasyPalletizer is multifunctional:

Palletizing at floor level

Reloading system (loading or unloading)

Double palletising system (2 pallets simultaneously)

Pictures show the EasyPalletizer with the robot from Universal Robots

Other robots on request.

Screwdriver for robots from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Screwdriver for robots

With the new intelligent OnRobot screwdriver for light industrial, cooperation and assembly robot you can easily automate processes. Intelligent error detection and handling of multiple screw sizes ensures consistent results and drastically reduces your cycle time.

Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Functionality

Due to the simple connection of the screwdriver and the operation and programming via the own URCap (only applies to Universal Robots) the grippers are ready for use in the shortest time.

In addition, the connection time is reduced by the OnRobot quick-change system Quick Changer and Dual Quick Changer.

Features of the Screwdriver

Automated bolting to increase productivity and quality has never been easier, smarter or more cost effective. The intelligent OnRobot screwdriver speeds setup and programming and gives you everything you need right out of the box. Simply mount the screwdriver on any assembly robot and install the appropriate bit, then enter screw length and torque directly into the robot?s user interface.

The precise torque control and embedded axis eliminate the time and cost of additional integration and ensure consistent, accurate screw insertion. Switching to a different screw type or size takes only minutes, reducing downtime and increasing ROI.

The OnRobot screwdriver and available screw feeders handle a wide range of screw sizes. This ranges from M1.6 to M6 and up to 50 mm in length. The precise torque control ranges from 0.15 Nm to 5 Nm. The OnRobot screwdriver is more versatile and intelligent than conventional tools. During the tightening process it detects whether the screw has been removed, is the correct length or has been inserted correctly.

The OnRobot screwdriver has protective functions that make it suitable for cooperative robot applications for screws up to 35 mm in length. During movement, the screws are fully retracted into the screwdriver.

The safety stop is automatically activated if a screw is subjected to excessive force along its axis. An alarm light indicates the problem.

Silicone gripper Soft Gripper from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Soft Gripper

The silicone gripper Soft Gripper from OnRobot can pick up a wide variety of irregular shapes and delicate objects. This makes it ideal for pick-and-place applications. The Soft Gripper is particularly suitable for applications in food and beverage production, manufacturing and packaging. The gripper is available with three interchangeable silicone-coated suction cups. Whether eggs, fruit, bottles or cans ? this silicone gripper from OnRobot makes food and beverage automation easier.

Like all OnRobot grippers, the Soft Gripper can be seamlessly integrated into the robot of your choice. The Soft Gripper operates without an external air supply, so there is no additional cost or complexity, and no dust or noise is generated as with conventional grippers.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Functionality

Due to the simple connection of the grippers and the operation and programming via the dedicated URCap (only applies to Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick change system Quick Changer and Dual Quick Changer.

Features of the silicone gripper SoftGripper

The new OnRobot Soft Gripper is available with three interchangeable, silicone-coated suction cups. This makes it suitable for a variety of irregular shapes and delicate objects. It is ideal for pick-and-place applications in food and beverage production. It is also suitable for other ?clean? production applications such as cosmetics and pharmaceuticals, as well as for manufacturing or packaging. The Soft Gripper comes with OnRobot?s revolutionary Quick Changer, a base unit and silicone suction cups in star or finger version for more flexibility.

The silicone suction cups of the Soft Gripper are dishwasher safe and comply with FDA 21 CFR (for fat-free food). It also comply to EC 1935/2004 regulation on materials and articles intended to come into contact with food. The maximum payload of 2.2 kg depends on the shape, softness and friction of the objects to be handled. The handle dimensions are between 11 mm and 118 mm depending on the suction cup used.

Available models:

? SG-a-H

? SG-a-S

? SG-b-H

Vacuum gripper VG10 from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Vacuum gripper VG10

Since the vacuum gripper VG10 does not require a compressor or an air supply, it is a compact and easy to move solution. This makes your production line more flexible and saves maintenance costs. It has flexible arms and an adjustable vacuum. This allows the VG10 to handle different objects in many different sizes. Furthermore, your efficiency is further increased because it is a double gripper. This means you can control the right and left side of the vacuum gripper independently of each other.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

The vacuum gripper is equipped with double gripper functionality, a tool changer and various common suction cup attachments.

In addition, there are many third party suction cup attachments on the market to suit any application.

Functionality

Due to the simple connection of the grippers and the operation and programming via the dedicated URCap (only applies to Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick change system Quick Changer and Dual Quick Changer.

Features of the VG10

The VG10 is a robotic gripping tool specifically designed for collaborative robotic applications. Unlike the vacuum gripper VGC10, the VG10 has an adjustable vacuum and adjustable gripper arms.

This makes it ideal for processes that involve workpieces of many different sizes and shapes.

The VG10 is a double suction pad. This means that you can activate the right and left side of the vacuum gripper to perform different tasks independently of each other. This shortens the passage time. The overall efficiency of your production line is increased.

The gripper has already integrated software that can be easily installed and programmed. This means that even employees without a technical background can carry out the setup.

Integrated electrical vacuum, therefore no external air supply is required. This saves maintenance costs and additional air ducts.

The suction cups can be easily replaced according to the requirements of the application. The reason for this is the configurable suction cups.

Vacuum gripper VGC10 from OnRobot

|

Handling of workpieces

Samsys GmbH

Handling of workpieces

Vacuum gripper VGC10

The compact, electric vacuum gripper VGC10 offers infinite adjustment possibilities. It also has optional suction cups for almost any application. The VGC10 is smaller than the VG10, making it suitable for tight environments where it can expand your automation capabilities. With the same payload, but half the weight of the VG10, the VGC10 can lift small, bulky and heavy objects even with a smaller robot arm. The VGC10 has two independently controlled air ducts. This allows it to be used as a double gripper with pickup and release in one action. This further increases efficiency and reduces throughput time. Since neither compressor nor air supply is required, this compact electric grab is easy to move. Easy programming allows it to be quickly reassigned, providing greater production flexibility.

Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

The vacuum gripper is equipped with double gripper functionality, a tool changer and various common suction cup attachments.

In addition, there are many third party suction cup attachments on the market to suit any application.

Ideal for packaging and palletizing, machine feeding or loading.

Functionality

Due to the simple connection of the grippers and the operation and programming via the dedicated URCap (only applies to Universal Robots), the grippers are ready for use in the shortest possible time.

In addition, the connection time is reduced by the OnRobot quick change system Quick Changer and Dual Quick Changer.

Features of the VGC10

The VGC10 is based on the award-winning VG10 electric vacuum gripper, but is smaller and lighter than its predecessor without sacrificing payload. This is an extremely adaptable gripper tool that allows manufacturers to focus on their application rather than on the complexity of the robot. This compact gripper is perfect for small spaces and smaller robot arms, while offering an impressive payload. Despite its compact size, this gripper tool can lift up to 15 kg.

Samsys-MZ Serie

|

Robot

Samsys GmbH

Handling of workpieces

Advantages:

- Smart cable routing

- Compact and flexible installation

- Easy programming

- Multipurpose usage

- Software Built-In PLC

UR 3/5/10, UR 3e/5e/10e/16e

|

Robotics

Samsys GmbH

Handling of workpieces

Advantages

- Quickly set up

- Simple programming

- Flexible use

- Kollaborierend and safely

- Fastest Time Automation in the industry