Samsys

Products

Samsys GmbH

Separators for coolants and lubricants, pumps, filters, centrifuges

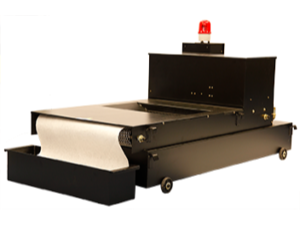

Paper belt filter Unimag PFA-20/-40/-60/-80/-120

Paper belt filter (PFA series) have been used for many years in many different applications. Due to the high filtration rate, autonomous operation and low operating costs, paper belt filters are already installed in a large number of workshops. Due to the accumulation of dirt on the filter membrane, better known as ?filter cake?, the final filtration accuracy is increased.

The filters are mainly used in machine tools. For example, in the machining of aluminium and cast iron. The belt filter is also often used for grinding and honing to achieve optimum surface roughness (RA).

The paper band filters are available in nine different capacities. Customer-specific requests are also possible. Within this PFA series there is always a paper belt filter for your lathe, milling machine and / or grinding machine. Our representatives can help you choose the right paper belt filter.

Features of the PFA series:

Applicable to both ferrous and non-ferrous particles

The filter paper automatically moves forward if impurities accumulate and clog it

The filtration effect depends on the paper accuracy. Choose between 50µ , 30µ and 15µ

For reasons of paper consumption, the belt filter is not suitable for heavy-duty processing. Use magnetic separator as pre-filter to reduce paper consumption

In general, the use of filter techniques means optimum care of the cooling lubricant used. This not only extends its service life, but also that of tools and pumps. There are significantly fewer blockages of pipes and fittings. In addition, slideways and guideways are subject to less wear and tear, and by keeping the grinding wheel open, a sustained higher grinding performance is achieved.

Fewer machine downtimes are another result of using filter techniques, because they remain clean and require less cleaning. They improve productivity through lower scrap rates. They also reduce operating costs.

Not forgetting a significant advantage: cleaned coolants attack the skin much less. So you protect the health of your employees at the workplace.

High pressure pump Profluid PF70-20DF/-30DF

|

Separator for coolants and lubricants, pumps, filters, centrifuges

Samsys GmbH

Separators for coolants and lubricants, pumps, filters, centrifuges

High pressure pump Profluid PF70-20DF/-30DF

The high pressure pump Profluid with double filter version have the advantage that their process does not have to be interrupted when one filter is full. You can simply close one filter with a 3-way ball valve and open the other to clean the dirty filter without interrupting the system.

The Profluid PF70-20DF/-30DF comes standard with feed pump, flow test, delta P switch, pressure relief valve and two 25 micron filter bags. It is suitable for CNC-lathe machines and milling machines, including vertical and horizontal machining centres and tapping centres.

The Profluid high pressure pumps with double filter are available in two different versions. There is also a series with a single filter and a series with a larger working pressure range. Within this Profluid series there is always a high pressure pump for your lathe or milling machine. Our representatives can help you to choose the right high pressure pump.

Recently, interest in high-pressure fluid has grown as machine tools tend to be high-speed and high-precision. At low pressure (below 14kgf/cm²), vapour barriers are created by the cutting speed of machine tools. This results in blocking of the cutting fluid. The cutting fluid loses its function before it can enter the cutting zone by evaporation. On the other hand, cutting fluid can reach the cutting zone under high pressure (over 20kgf/cm²). You can achieve the following:

1. Frictionless lubrication and cooling effect

2. The cutting ability is improved

3. Improvement of tool life by eliminating the phenomenon of chip regrooving

4. Improvement of the cut surface roughness

5. Smooth chip removal effect

6. deburring effect

7. Smooth cut and improvement of the cutting ability for special processes such as deep hole machining and difficult to cut material processing

A comparison between a conventional cutting fluid and a 70kgf/cm² high pressure cutting fluid shows the following result:

20% reduction in cycle time due to improved cutting speed and feed rate

50% improvement in tool life

characteristics when drilling, boring etc.:

The cutting fluid is fed to a machining point with the highest pressure.

Chips are effectively discharged from a deep hole by reflected pressure and cutting fluid.

The drill can perform a more difficult machining operation and thus reduce the working time.

The life of the tool is significantly increased compared to the use of low pressure cutting fluid.

Features when turning:

Spraying cutting fluid directly at a machining point will create a greatly reduced heat zone.

Cutting chips into small pieces increases the chip removal capacity. Thus we prevent the re-cutting of chips. This results in a longer tool life.

Depending on the application, a cutting hydraulic wedge effect can be generated. This reduces tool wear by cooling the contact zone between chip and tool.

Paper belt filter Unimag PFA-160/-240/-360/-500

|

Separator for coolants and lubricants, pumps, filters, centrifuges

Samsys GmbH

Separators for coolants and lubricants, pumps, filters, centrifuges

Paper band filter (PFA series) have been used for many years in many different applications. Due to the high filtration rate, autonomous operation and low operating costs, paper belt filters are already installed in a large number of workshops. Due to the accumulation of dirt on the filter membrane, better known as ?filter cake?, the final filtration accuracy is increased.

The filters are mainly used in machine tools. For example, in the machining of aluminium and cast iron. The band filter is also often used for grinding and honing to achieve optimum surface roughness (RA).

The paper band filter are available in nine different capacities. Customer-specific requests are also possible. Within this PFA series there is always a paper belt filter for your lathe, milling machine and / or grinding machine. Our representatives can help you choose the right paper belt filter.

Features of the PFA series:

Applicable to both ferrous and non-ferrous particles

The filter paper automatically moves forward if impurities accumulate and clog it

The filtration effect depends on the paper accuracy. Choose between 50µ , 30µ and 15µ

For reasons of paper consumption, the belt filter is not suitable for heavy-duty processing. Use magnetic separator as pre-filter to reduce paper consumption

In general, the use of filter techniques means optimum care of the cooling lubricant used. This not only extends its service life, but also that of tools and pumps. There are significantly fewer blockages of pipes and fittings. In addition, slideways and guideways are subject to less wear and tear, and by keeping the grinding wheel open, a sustained higher grinding performance is achieved.

Fewer machine downtimes are another result of using filter techniques, because they remain clean and require less cleaning. They improve productivity through lower scrap rates. They also reduce operating costs.

Not forgetting a significant advantage: cleaned coolants attack the skin much less. So you protect the health of your employees at the workplace.

trommelfilter, drum filter Drum filter Unimag DF-140/-200/-360/-500/-1000/-1500/-2000

|

Separator for coolants and lubricants, pumps, filters, centrifuges

Samsys GmbH

Separators for coolants and lubricants, pumps, filters, centrifuges

Drum filter

In addition to standard paper belt filters, we also offer compact drum filter that require little space in terms of space requirements. Due to the hydrostatic pressure of the medium on the filter web a very efficient filtration is achieved. These compact drum filters are available up to a capacity of 2000 litres per minute. The DF series can be supplied with any tank required.

They are available in seven different capacities. The tank is manufactured according to customer-specific requirements. Due to the compact design and the enormous capacities of this drum filter, these belt filters are particularly suitable for workshops with limited space.

The drum filter are available in seven different capacities You can use the compact drum filter for the filtration of your lathe, milling machine and / or grinding machine. Our representatives can help you choose the right paper belt filter.

Features of the drum filter DF:

Consume only 1/3 of the space of a conventional paper filter

Suitable for coolant filtration to extend the X-change frequency of the coolant

Available for filtering coolant from ferrous, non-ferrous and non-metallic materials

Fully automatic discharge to produce a clean coolant. Thereby you create a brilliant surface of the workpiece.

The filtration effect depends on the paper belt. Select 50µ, 30µ or 15µ

Available to be equipped with a magnetic separator for coarse filtration. This allows you to reduce filter paper consumption satisfactorily.

An optimal machining process requires the removal of contaminants such as chips, oil and other dirt particles. Continuous cleaning of coolant prevents the health of people, smelly cooling water, corrosion on workpieces, clogging of cooling channels and excessive wear on machine components. Dormatec offers various options for liquid filtration.

In general, the use of filtration techniques means optimum care of the cooling lubricant used. This not only extends its service life, but also that of tools and pumps. There are significantly fewer blockages of pipes and fittings. In addition, slideways and guideways are subject to less wear and tear, and by keeping the grinding wheel open, a sustained higher grinding performance is achieved.

Fewer machine downtimes are another result of using filter techniques, because they remain clean and require less cleaning. They improve productivity through lower scrap rates. They also reduce operating costs.

Not forgetting a significant advantage: cleaned coolants attack the skin much less. So you protect the health of your employees at the workplace.

Vessel Filter Profluid MCF 20

|

Separator for coolants and lubricants, pumps, filters, centrifuges

Samsys GmbH

Separators for coolants and lubricants, pumps, filters, centrifuges

Vessel filter Profluid MCF 20.

The Profluid vessel filter are equipped with an integrated delta P-meter. If the filter bag is dirty, this differential pressure sensor gives a signal. The filters are available in 5, 10, 25 and 50µm. If you use a duplex setup, you can change the filter bag without switching off the instrument. This facilitates maintenance. So you minimize the downtime of your machine. The result is increased productivity.

Lathes, milling machines or grinding machines with an operating pressure of up to 20 bar require protection against abrasive particles such as chips and other contaminants. Especially for this application up to 20 bar we have a Profluid vessel filter in our program, which can be easily mounted on existing machines and pumps.

In general, the use of filter techniques means optimum care of the cooling lubricant used. This not only extends its service life, but also that of tools and pumps. There are significantly fewer blockages of pipes and fittings. In addition, slideways and guideways are subject to less wear and tear, and by keeping the grinding wheel open, a sustained higher grinding performance is achieved.

Fewer machine downtimes are another result of using filter techniques, because they remain clean and require less cleaning. They improve productivity through lower scrap rates. They also reduce operating costs.

Not forgetting a significant advantage: cleaned coolants attack the skin much less. So you protect the health of your employees at the workplace.